Motor bearing state monitoring and early warning device

A state monitoring and early warning device technology, applied in the direction of temperature measurement of moving solids, can solve the problems such as rapid damage of arc-shaped metal sheets and temperature sensors, low life of arc-shaped metal sheets and temperature sensors, and inability to monitor bearings. Good effect, high practicability, and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

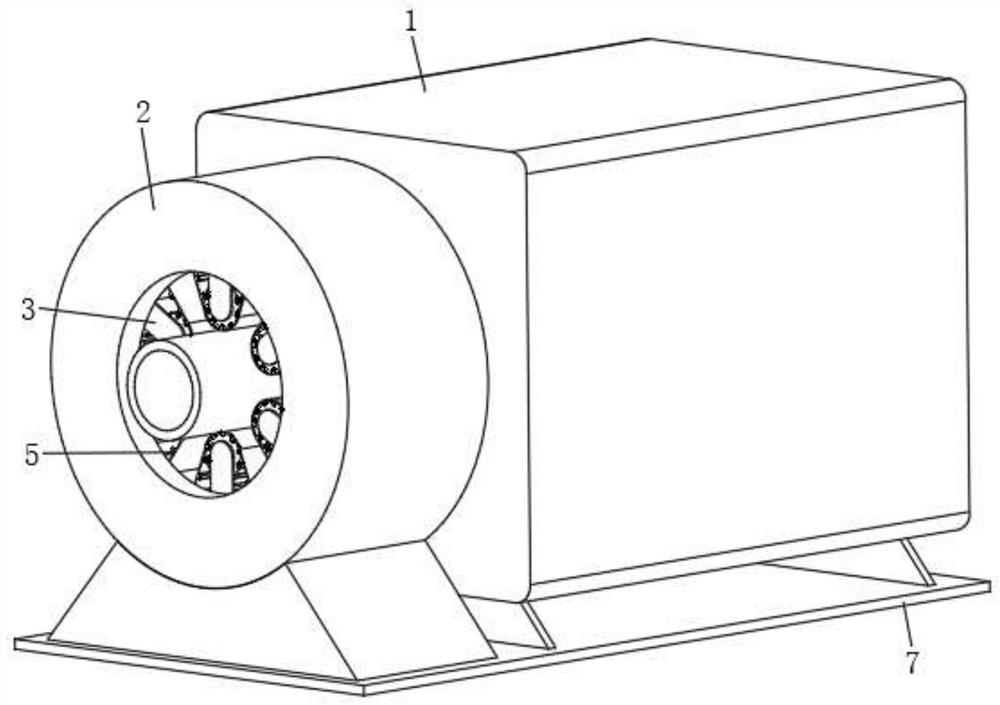

[0032] see Figure 1 to Figure 4 , the embodiment of the present invention provides a motor bearing state monitoring and early warning device: comprising a mounting seat 7 and a motor body 1 and a bearing seat 2 fixedly connected with the mounting seat 7, the bearing seat 2 is sleeved on the outside of the bearing of the output shaft of the motor body 1 ; The mounting seat 7 and the motor body 1 are existing mature technologies, and will not be described in detail here; the bottom of the bearing seat 2 is fixedly connected with the mounting seat 7, and its upper part is arranged in an annular sleeve outside the bearing, and the interior is hollow An annular placement groove is arranged and runs through the inner wall.

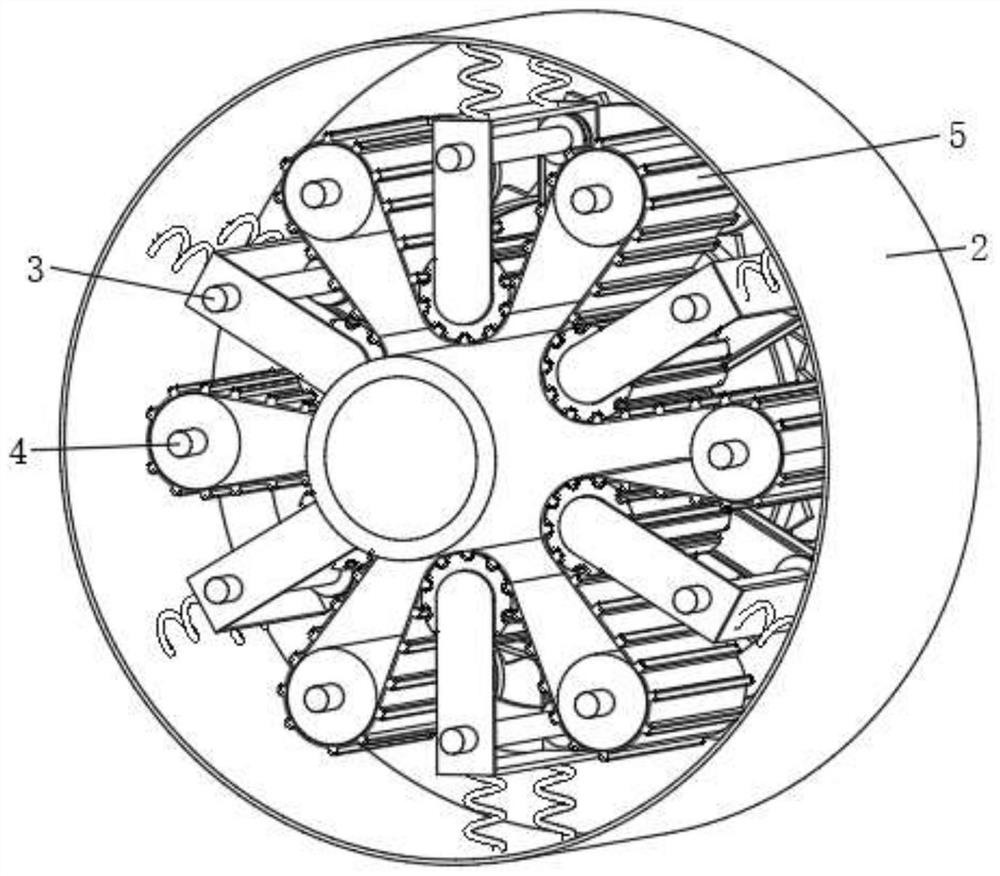

[0033] The internal movement of the placement groove is provided with a detection component 5 for monitoring the state of the bearing, and the internal movement of the bearing seat 2 is provided with several rotating components 3 and several connecting componen...

Embodiment 2

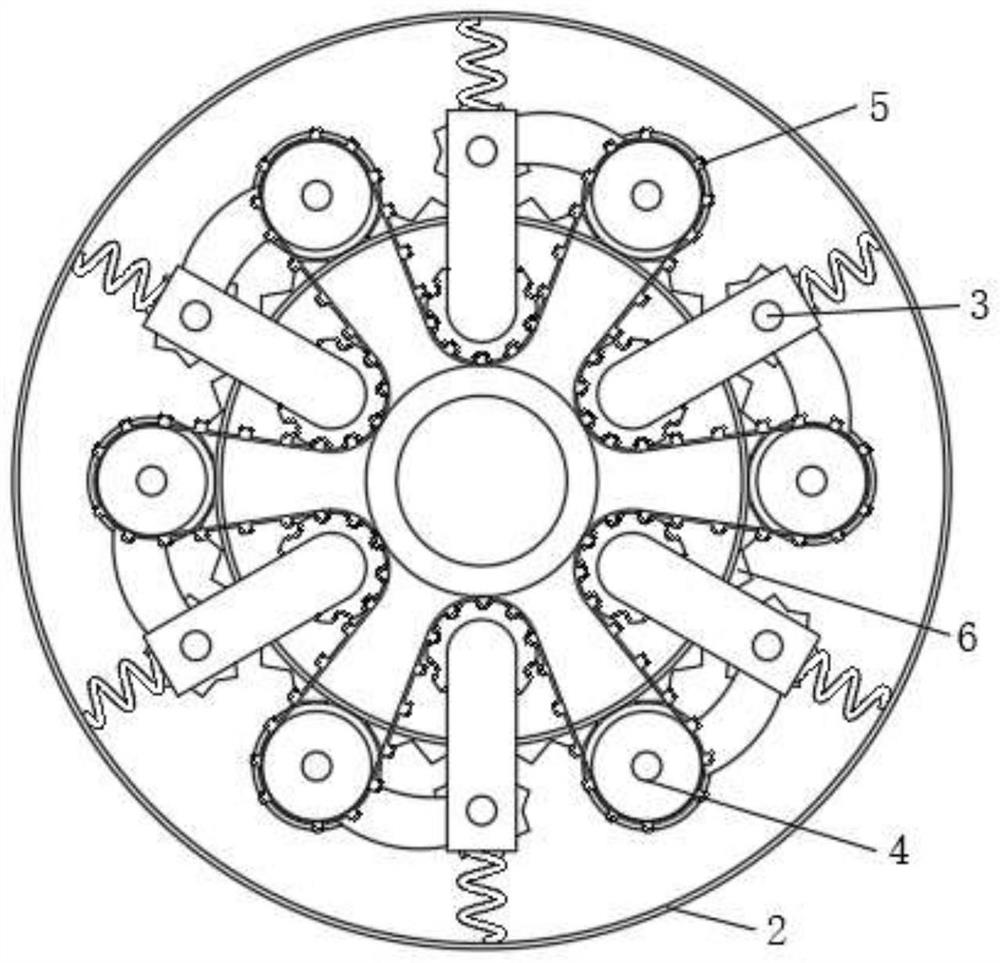

[0038] see Figure 1 to Figure 10On the basis of the first embodiment, the rotating assembly 3 includes a U-shaped bracket 301 located inside the placement groove, and a first spring 302 is provided between the surface of the U-shaped bracket 301 away from the bearing and the inner wall of the bearing seat 2. The first spring 302 It is fixedly connected to the U-shaped bracket 301 without being fixedly connected to the bearing seat 2. Because the first spring 302 is provided, the U-shaped bracket 301 tends to move relative to the bearing, and the first spring 302 can make the detection assembly 5 It can better contact with the bearing, so that the detection component 5 can better detect data; the surface of the U-shaped bracket 301 is penetrating and rotatably installed with a first support rod 303, and the end of the first support rod 303 is fixedly installed with a gear ring. 6. The gear 305 is connected by a transmission. A second support rod (not shown in the figure) is fi...

Embodiment 3

[0047] see Figure 1 to Figure 10 , on the basis of the second embodiment, a second spring (not shown in the figure) is arranged between the connecting rod 401 and the inner wall of the bearing seat 2, the second spring is arranged on the side of the connecting rod 401 close to the bearing, the second spring Not being fixedly connected with the connecting rod 401 and the bearing seat 2 will not affect the rotation of the connecting rod 401, but under the action of the second spring, the connecting rod 401 tends to move away from the bearing.

[0048] In this embodiment, it is preferred that when the elastic metal belt 501 rotates itself and rotates relative to the bearing under the action of the rotating roller 306 and the cylinder 402, its moving route is from below the rotating roller 306 through the cylinder 402 Above, and then below the next rotating roller 306, because the second spring is provided, the connecting rod 401 and the cylinder 402 have a tendency to move away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com