Crude product separation and impurity removal mechanism for hydraulic ring sample analysis

A technology for sample analysis and crude products, which is used in the preparation of test samples, grain processing, etc., and can solve problems such as the inability to achieve complete drying of soil samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

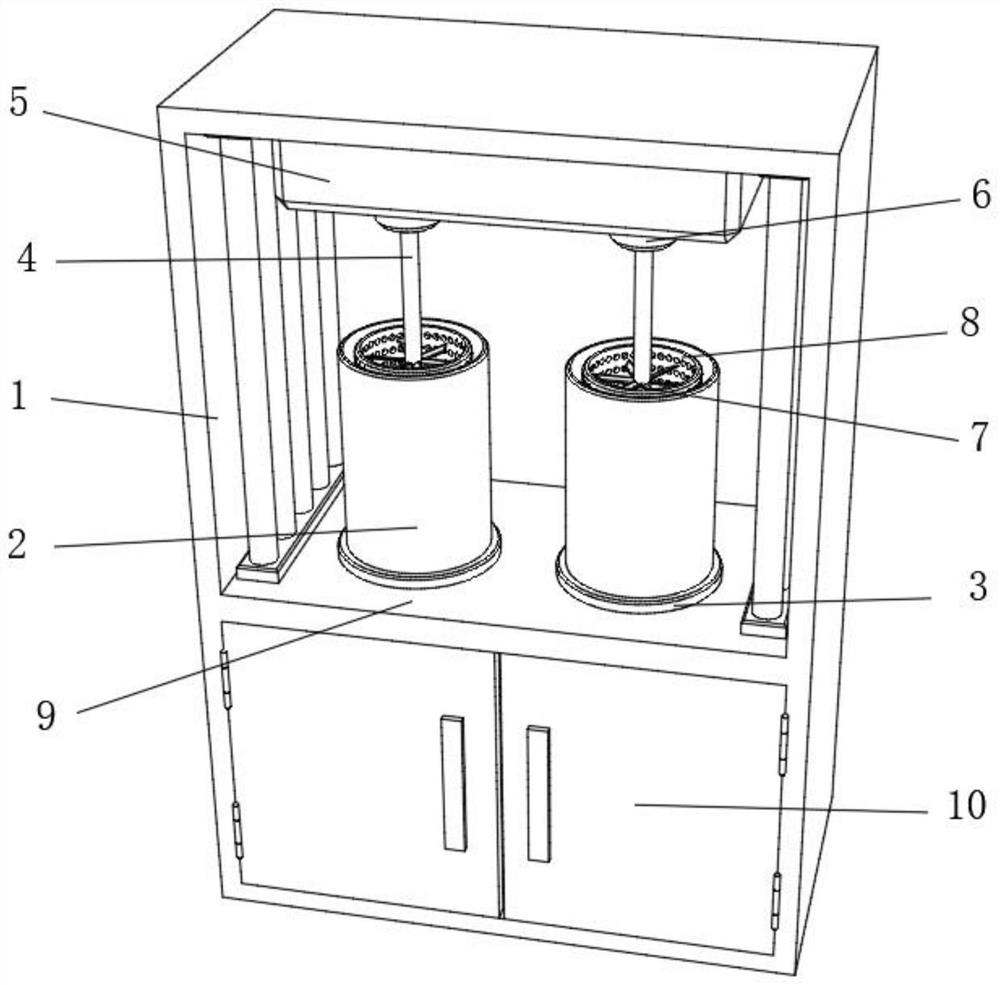

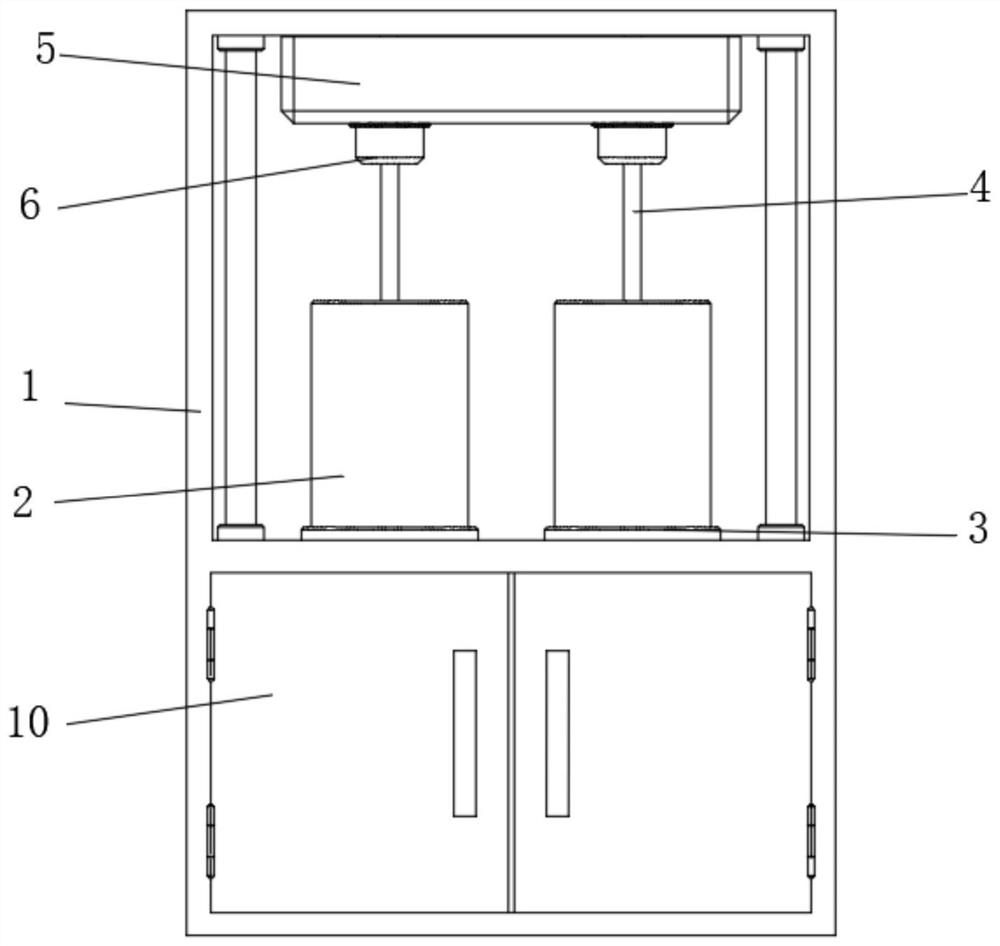

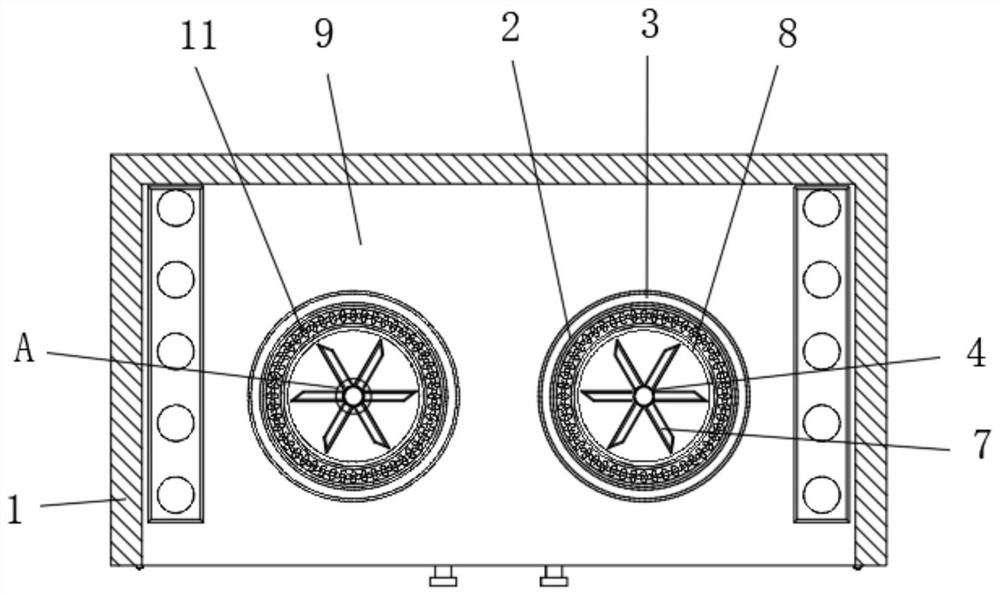

[0026] like Figure 1-6 As shown, the embodiment of the present invention provides a crude product separation and impurity removal mechanism for hydraulic ring sample analysis, comprising a device main body 1, the upper part of the device main body 1 is provided with a top bin 9, and the left and right sides of the inner bottom of the top bin 9 are threadedly connected with The fixing seat 3, the top middle of the fixing seat 3 is threadedly connected with a sieve cylinder 8, the outer side of the top middle of the fixing seat 3 is threadedly connected with the outer cylinder 2, the outer circumference of the sieve cylinder 8 is uniformly distributed with air outlet holes 23, and the interior of the sieve cylinder 8 is threaded. Both are provided with evenly distributed crushing knives 7, the crushing knives 7 are fixedly connected to the lower part of the outer circumference of the rotating shaft 4 respectively, and the top of the rotating shaft 4 runs through the empty bin 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com