TM0-TE1 optical mode converter based on double-layer curve edge waveguide structure and optical device

A technology of TM0-TE1 and waveguide structure, which is applied in the field of integrated photonics, can solve the problems that it is difficult to take into account the compact size of the device and high conversion efficiency at the same time, achieve high mode conversion efficiency, ensure smoothness, and ensure the effect of manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] see Figure 4-Figure 5 , the material of the ridge layer and the plate layer is set to silicon, the periphery of the waveguide is set to silicon dioxide, the thickness H2 of the plate layer is set to 90nm, and the height H1 of the top of the ridge layer relative to the bottom of the plate layer is set to 220nm.

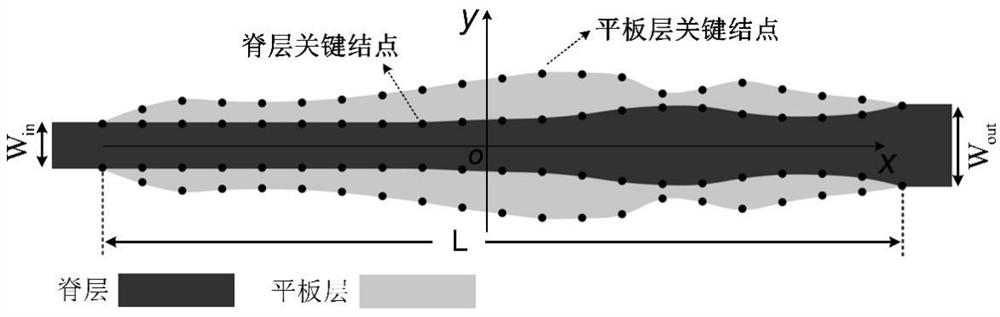

[0035] Introduce the wave into the port width W in Fixed at 440nm, the waveguide exit width W out It was fixed at 800 nm, and the device length L was fixed at 8 μm. The device has an axisymmetric structure along the light propagation direction. We set 21 equally spaced key nodes for each edge of the ridge-layer and slab-layer waveguides, and connected them through quadratic spline interpolation.

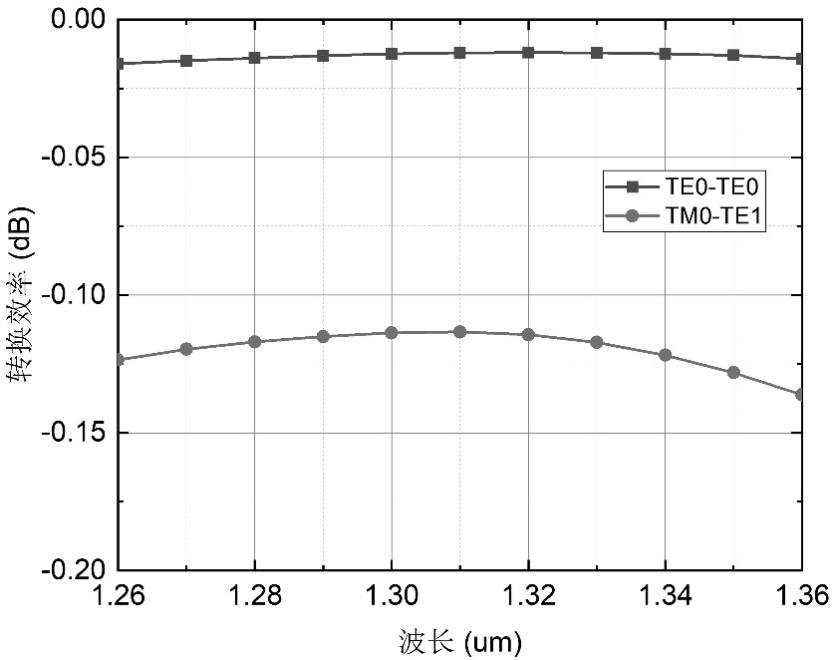

[0036] We fixed the position of the first node, and optimized the ordinates of the 38 free nodes in the middle using the adjoint optimization method based on 3-dimensional finite difference time domain (FDTD). The optimization goal was to maximize the conversion ef...

Embodiment 2

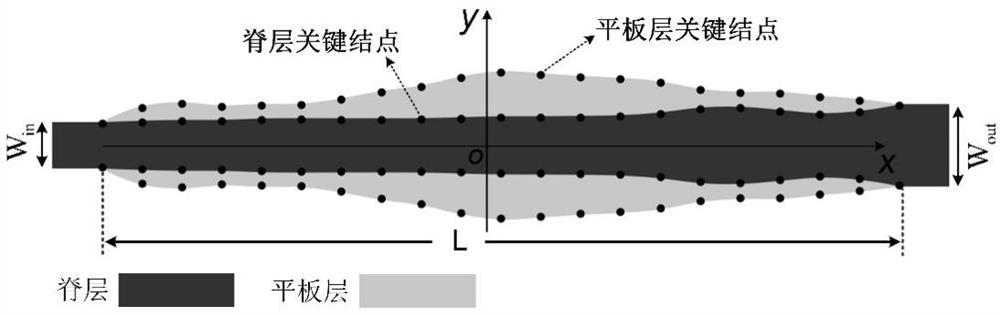

[0039] see Figure 6-Figure 7 , and then the thickness of the slab layer H 2 Change to 70nm, keep other materials and parameters unchanged, reuse the concomitant optimization method based on 3-dimensional finite difference time domain (FDTD) to optimize the ordinates of the 38 free nodes in the middle. The final optimized mode converter structure is as follows Image 6 As shown, it has a smooth waveguide edge shape and is easy to fabricate. The conversion efficiency obtained by 3D FDTD simulation is as follows Figure 7 As shown, it still has very high TM0-TE1 mode conversion efficiency and TE0-TE0 mode transmittance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com