Device for a microactuator, and microactuator equipped with such a device

A micro-actuator and actuator technology, applied in the field of micro-actuator devices and micro-technical fixture devices, can solve problems such as high asymmetry, complexity, and vulnerability, and achieve easy manufacturing and a small number of parts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

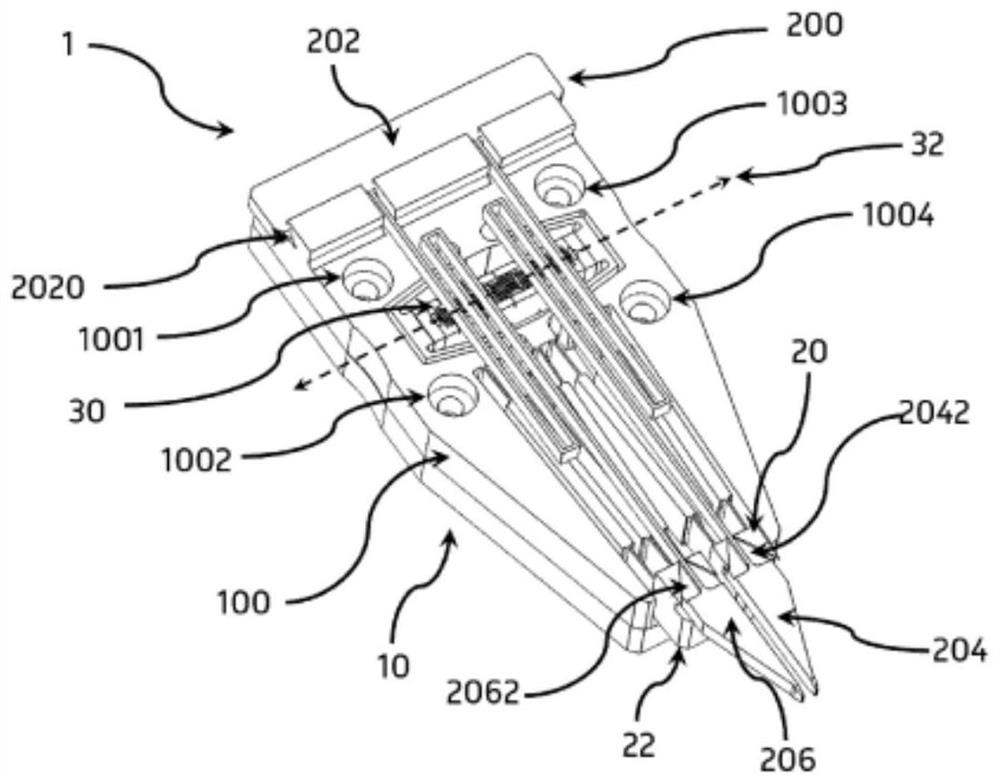

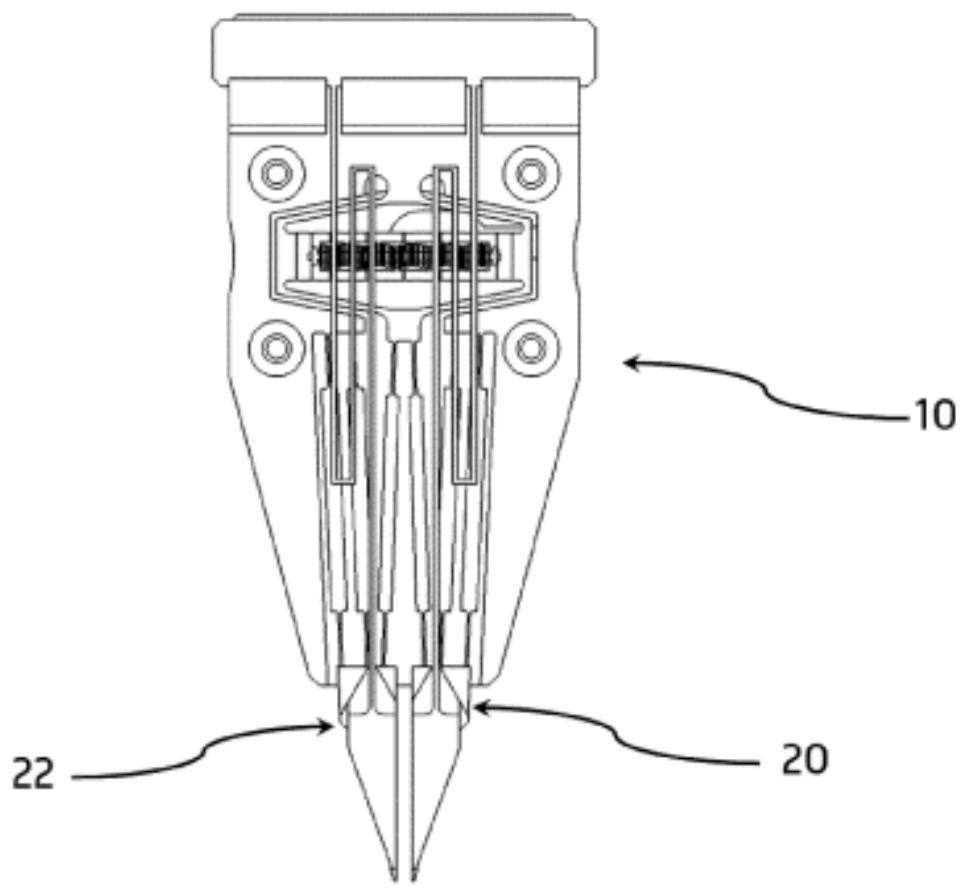

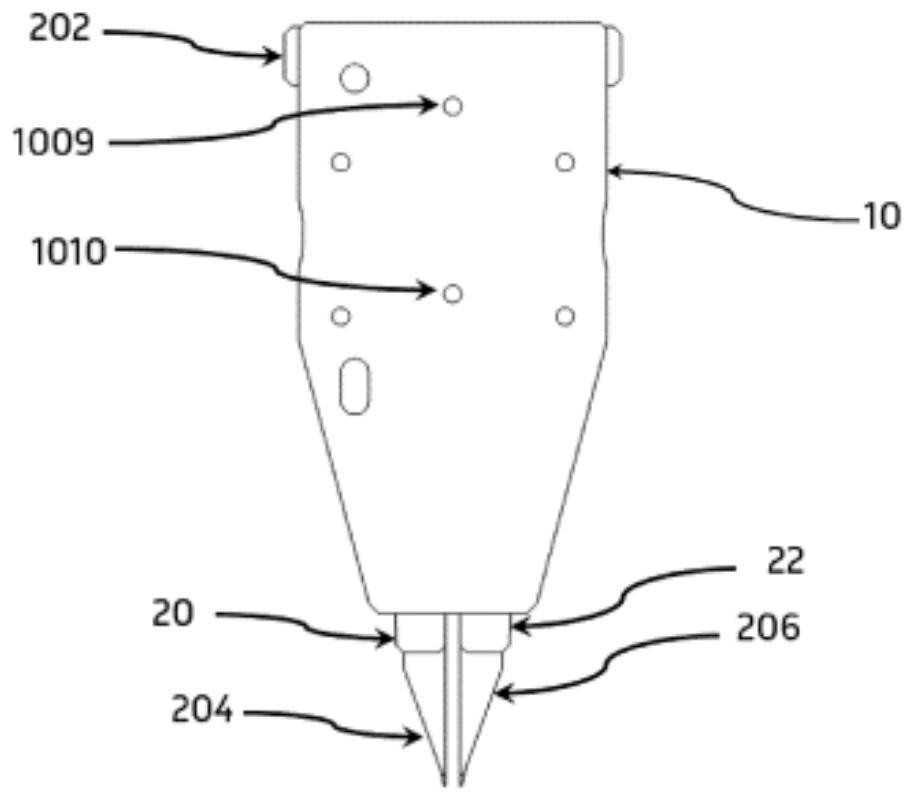

[0043] reference now Figure 1 to Figure 6 .

[0044] The microactuator 1 includes a base 10 , two terminal members 20 and 22 , and an actuator 30 that actuates the terminal members 20 and 22 .

[0045] In one embodiment, the microactuator 1 is a microtechnology clamp and the terminal members are gripping members, such as finger carriers, each of which can receive a finger. The actuator 30 can actuate the finger carriers 20 and 22 in order to perform grasping by the microactuator 1 .

[0046] The finger carriers 20, 22 can receive respective fingers to form a microtechnology fixture. In one embodiment, the microactuator 1 comprises an end piece 200 mounted on the base 10, comprising a support piece 202 and two fingers 204 and 206 connected to the support piece 202 by corresponding flexible connecting elements 2040, 2060 , such as described in the applicant's patent EP2718066. Each finger 204, 206 includes a respective fastening base 2042, 2062 by means of which the finger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com