Double-magnetic driving system for optical-mechanical system of electronic equipment

A drive system and dual-drive technology, applied in electric components, propulsion systems, optics, etc., can solve problems affecting image resolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

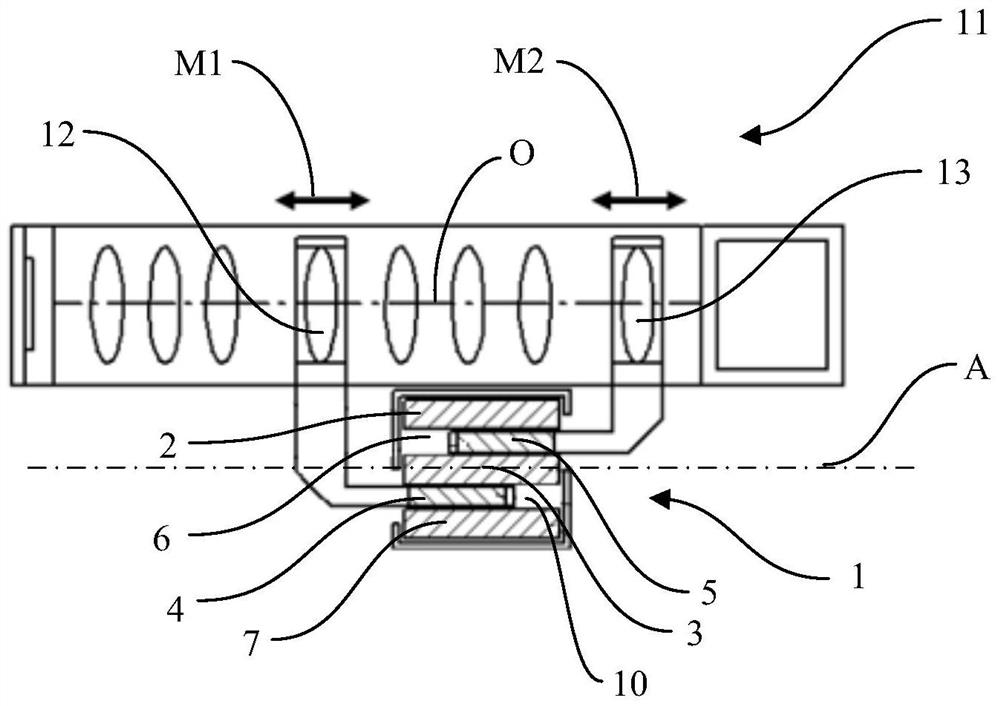

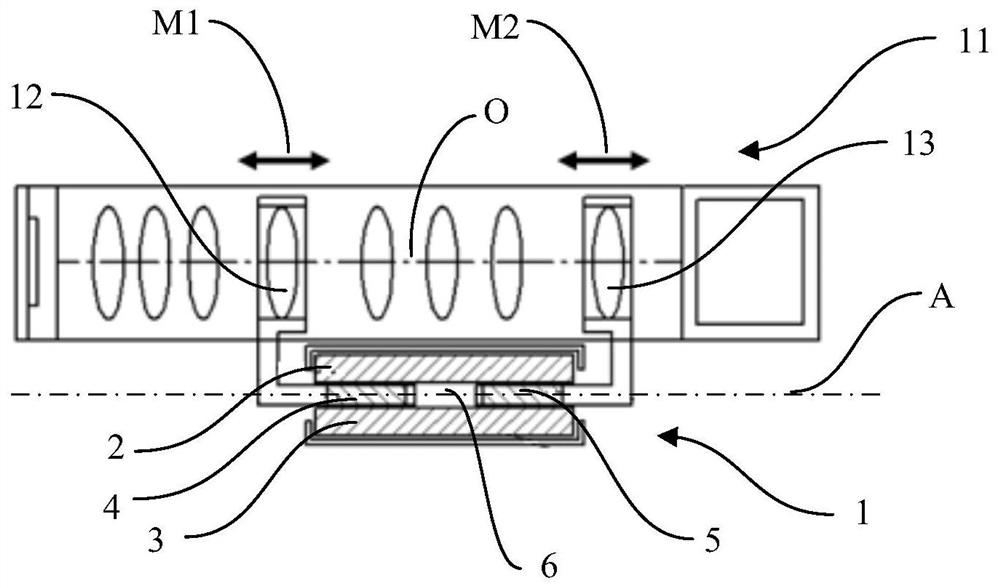

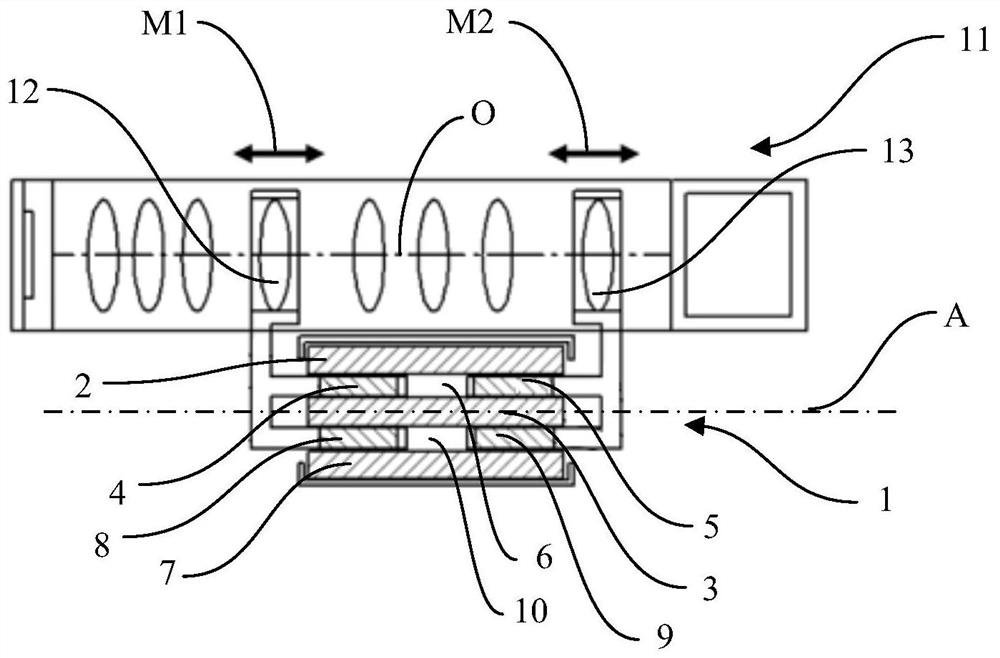

[0032] The invention relates to a dual drive system 1 with a common drive shaft A. The drive system 1 includes at least a first magnet 2 , a second magnet 3 , a first coil 4 and a second coil 5 . The first magnet 2 , the second magnet 3 , the first coil 4 and the second coil 5 are arranged in a direction perpendicular to the drive axis A in an at least partially overlapping manner.

[0033] The drive system 1 operates by: operating the current in the first coil 4, which produces a first movement M1 along the drive axis A; operating the current in the second coil 5, so The current produces a second movement M2 along the drive axis A. The first movement M1 and the second movement M2 are independent of each other. The first movement M1 and the second movement M2 may be generated simultaneously. Further, the first movement M1 and the second movement M2 may be generated in the same direction of the drive axis A and / or in opposite directions of the drive axis A.

[0034] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com