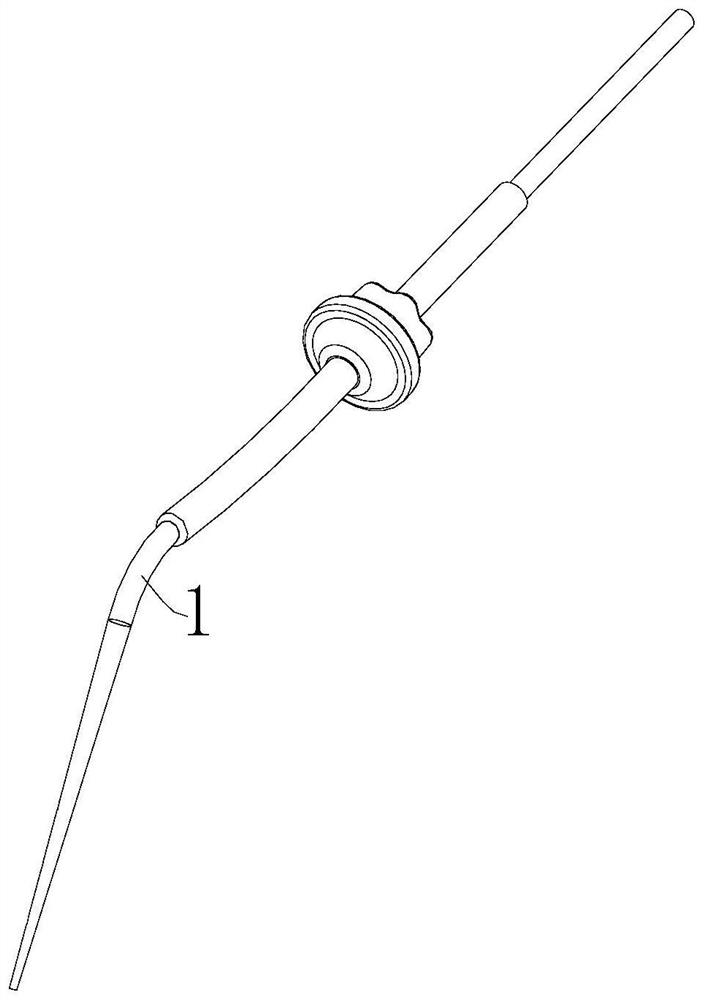

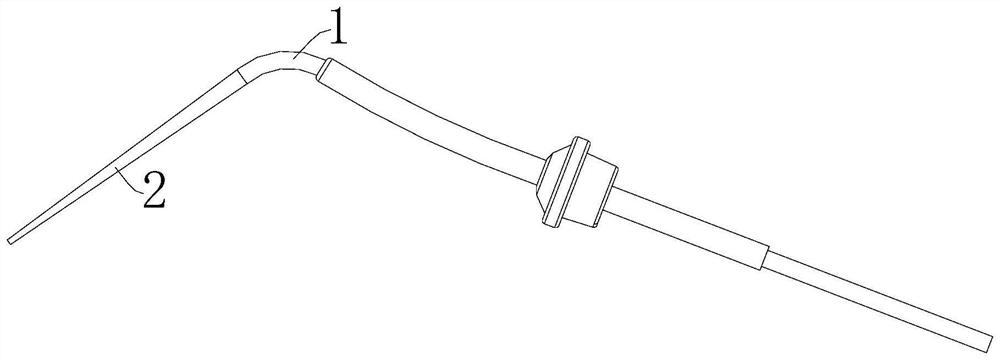

Work tip for hot melting gutta-percha filling machine

A glue filling machine and working tip technology, used in dentistry, filling teeth, dental prosthetics, etc., can solve problems such as low friction, treatment impact, and residual gutta percha

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0021] Embodiment 2 of the present invention is a working tip for a hot-melt gutta-percha filling machine. On the basis of Embodiment 1, the rough surface 2 is a sandblasting layer or a diamond-coated layer. The sandblasting layer or the emery-plated layer has stable properties, is not easy to fall off the working tip 1, and has high hardness, fine sand grains, and a large adhesion area of the gutta-percha tip.

Embodiment 3

[0022] Embodiment 3 of the present invention is a working tip for a hot-melt gutta-percha filling machine. On the basis of Embodiment 1, the rough surface 2 is a grooved layer. The multi-groove structure in the grooved layer can increase the adhesion area of the gutta-percha tip, improve the friction force, and does not affect the heat conduction performance of the working tip body, the structure is simple, and the completion efficiency is high.

Embodiment 4

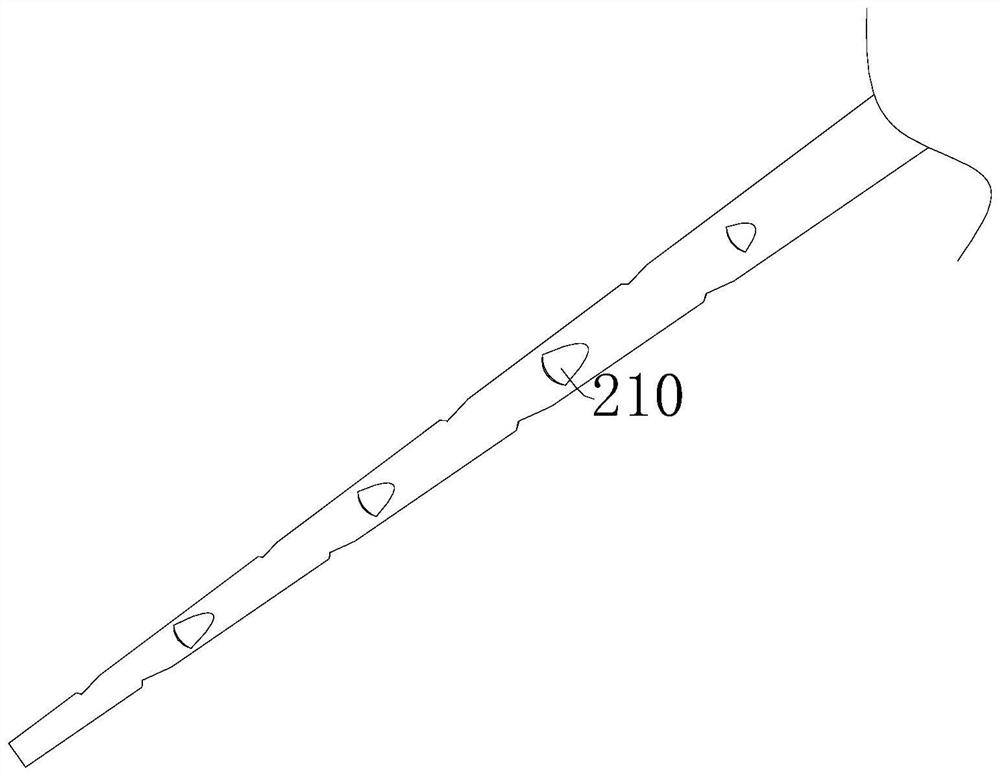

[0023] Embodiment 4 of the present invention is a working tip for a hot-melt gutta-percha filling machine. On the basis of Embodiment 3, a plurality of block-shaped grooves 210 are staggered on the grooved layer. Part of the gutta-percha tips after hot-melting flow into the block-shaped groove 210 to increase the adhesion area of the gutta-percha tips, so that the gutta-percha tips are more easily attached to the outside of the working tip body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com