Multi-runner printing device based on battery pole piece coating and printing method thereof

A technology for printing devices and battery pole pieces, which is used in devices for coating liquid on the surface, electrode manufacturing, coating, etc. It can solve the pulsation of slurry supply, poor consistency of pole piece coating thickness, and unstable discharge flow. and other problems, to achieve the effect of reducing fluid vortex and disturbance, improving drying shrinkage stability, and improving discharge stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

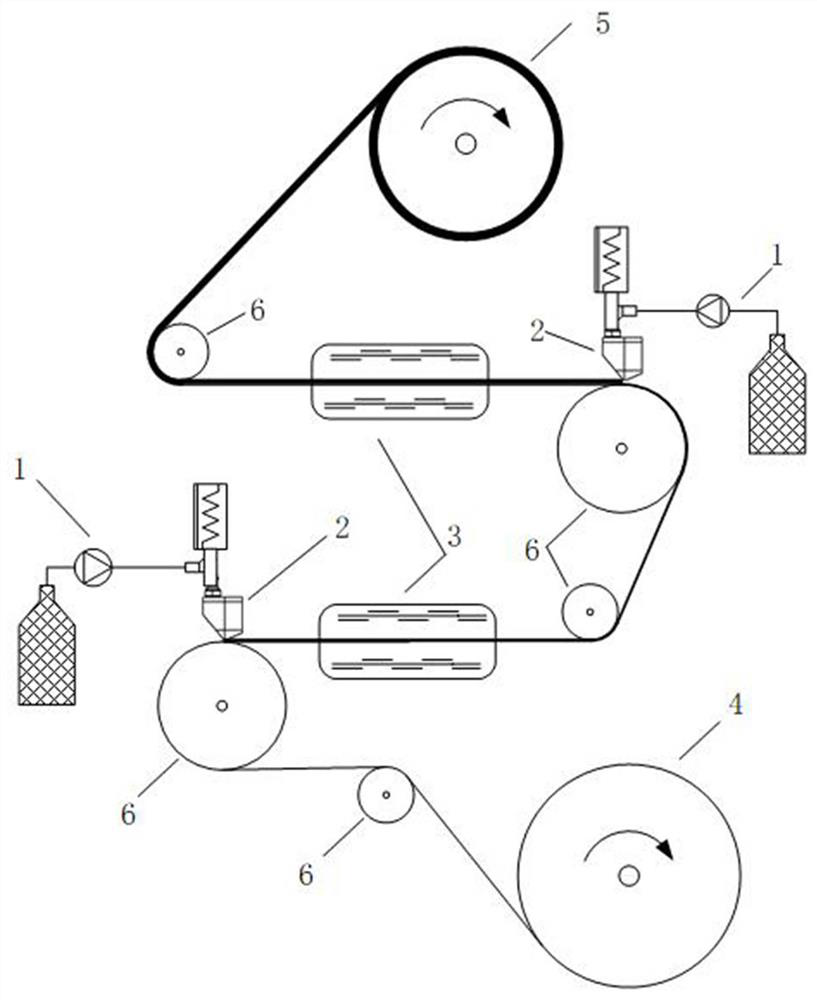

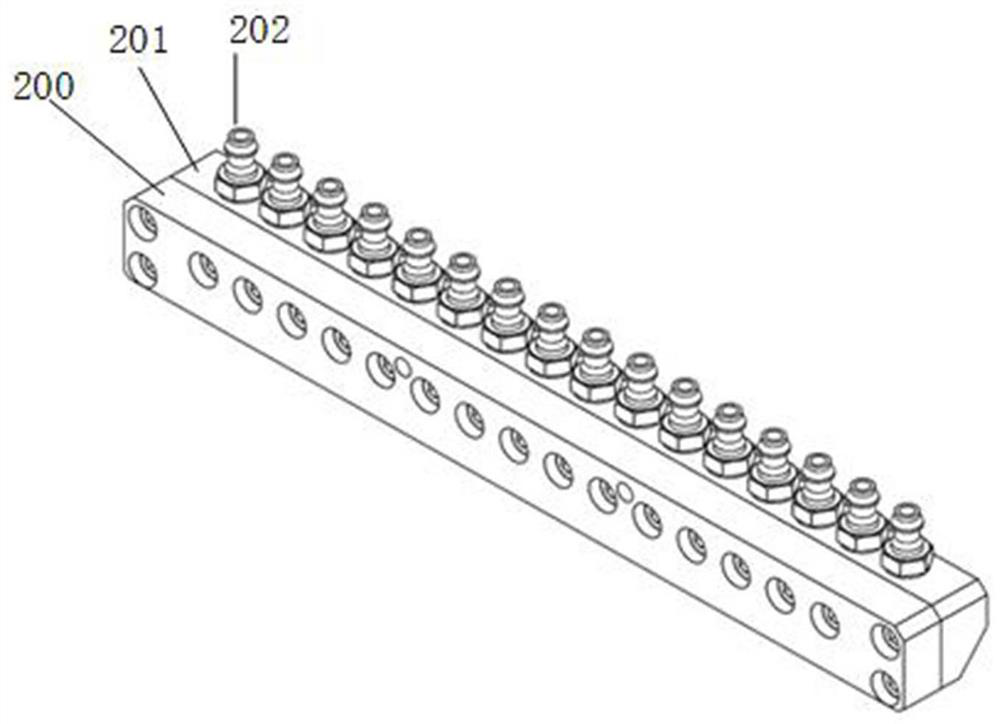

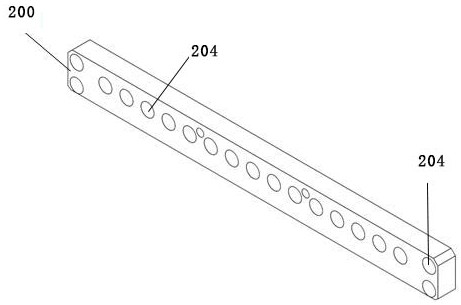

[0056] like Figure 1-13 As shown, a multi-channel printing device based on the coating of battery pole pieces includes a slurry distribution plate 200, a slurry distribution pressure plate 201 and a supply joint 202, and the slurry distribution plate 200 and the slurry distribution platen 201 are connected to form a flow The feed joint 202 is communicated with the flow channel, and the flow channels form a plurality of separate flow distribution units 206, and the plurality of flow distribution units 206 are formed on the slurry flow distribution platen 201. The length direction is equidistantly arranged; the splitting unit 206 forms a multi-stage two-split flow channel from top to bottom, and the cross-sectional area of each stage split flow channel is equal to the sum of the cross-sectional areas of the next-order two connected split flow channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com