Ultrasonic wire drawing system and wire drawing process

An ultrasonic and wire drawing technology, applied in the field of ultrasonic wire drawing system and wire drawing process, can solve problems such as the limitations of hot drawing and cold drawing process, optimize tensile strength and elongation at break, improve strength and hardness, and reduce internal stress piles poly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

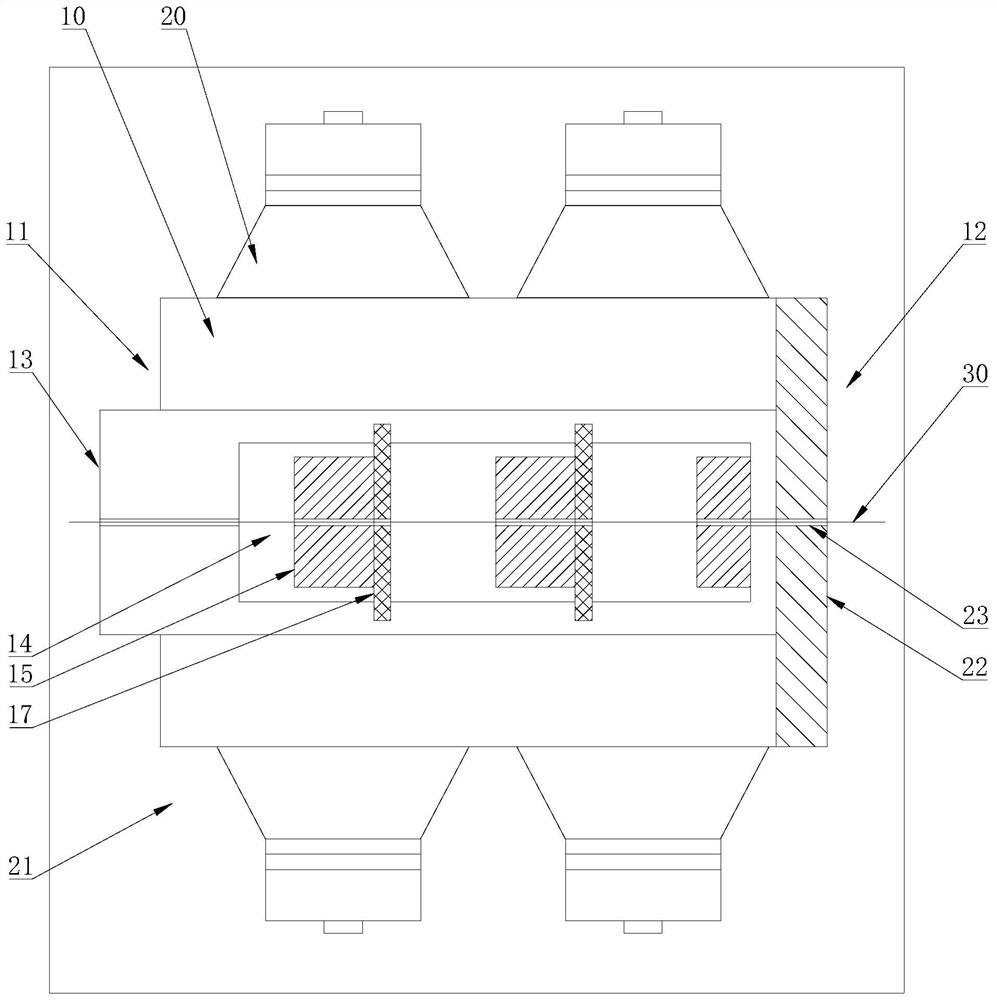

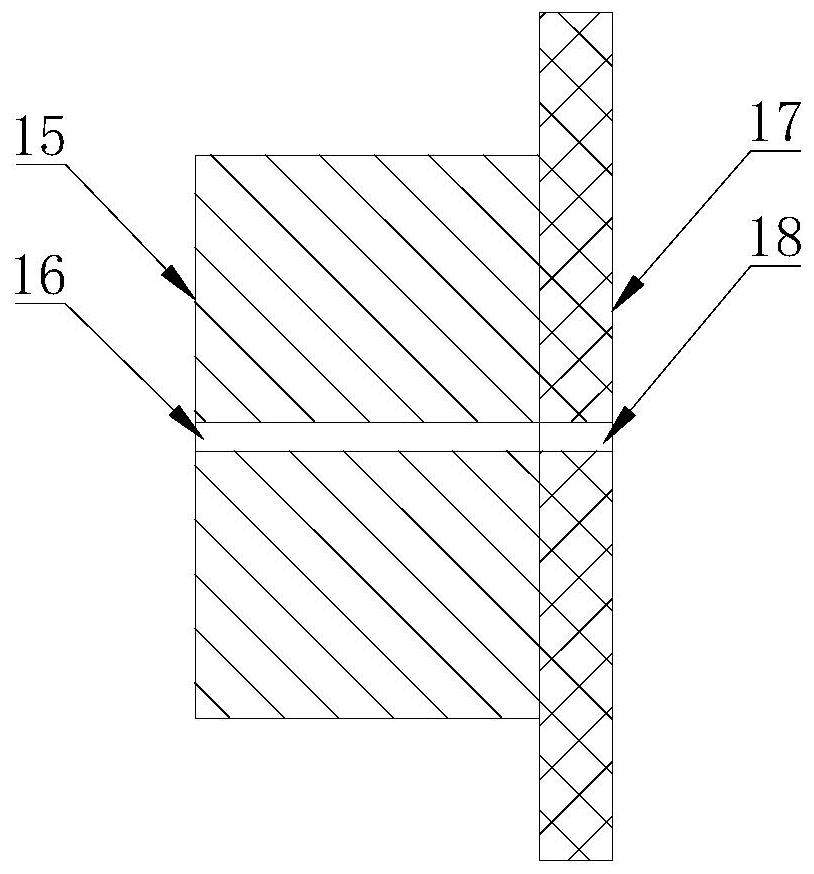

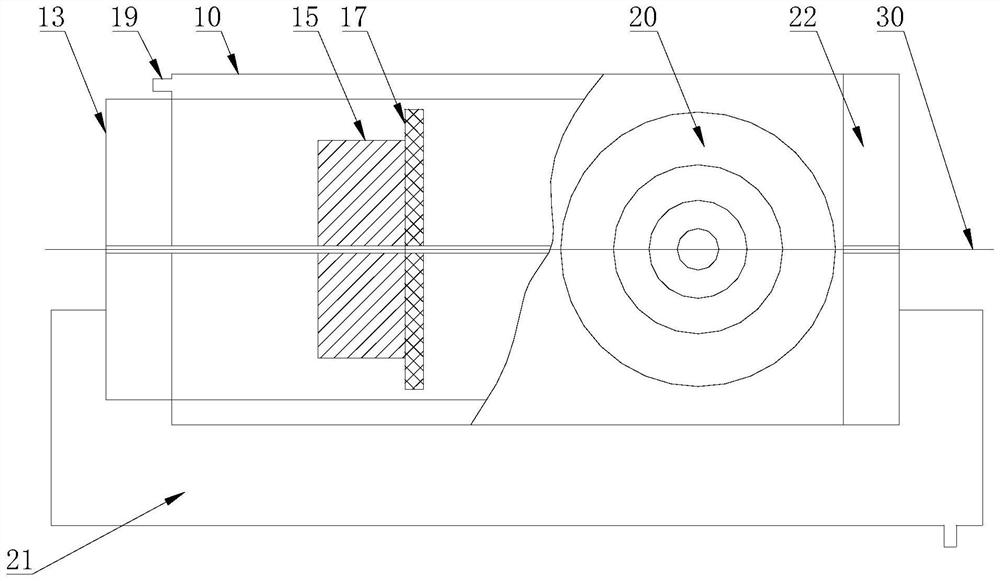

[0028] refer to figure 1 and image 3 , an ultrasonic wire drawing system, comprising: a wire drawing machine 10 and an ultrasonic generating device 20 communicating with the inner cavity of the wire drawing machine 10 . The number of ultrasonic generating devices 20 is four, which are respectively arranged on both sides of the wire drawing machine 10, and the arrangement direction is consistent with the moving direction of the wire material 30 during the wire drawing process. Ultrasonic wire drawing treatment of the wire material 30 .

[0029] The wire drawing machine 10 includes: a wire input end 11 and a wire output end 12 . The wire 30 to be drawn is drawn from the corresponding wire feed end 11 and passed out from the wire output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com