Manufacturing process of internal combustion engine connecting rod

A manufacturing process and internal combustion engine technology, applied in the direction of connecting rods, mechanical equipment, shafts and bearings, etc., can solve the problems of non-dense internal chemical composition, uneven structure of connecting rod blanks, large deviations, etc., and achieve good breaking effect, Effects of increasing stiffness and increasing preload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, objectives, and effects of the invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

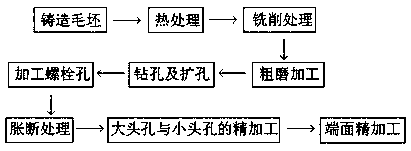

[0037] A kind of internal combustion engine connecting rod manufacturing process

[0038] Step 1: casting blank

[0039] Select the metal solution of 40Cr alloy steel and add it into the casting mold, put the powder material in the connecting rod cover and connecting rod body in the cavity of the casting mold, so that the powder material and the metal solution form a fracture after casting and water cooling The limit is to make a connecting rod blank, the casting molding error is less than 0.6 mm, the casting molding temperature is 1200 degrees Celsius, the casting molding time is 1.4 hours, the water cooling temperature is 20 degrees Celsius, and the cooling time is 50 minutes;

[0040] Step 2: Heat Treatment

[0041] First heat the connecting rod to 600 degrees Celsius, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com