Novel slab crystallizer

A crystallizer and slab technology, which is applied in the field of new slab crystallizers, can solve problems such as the complex structure of the internal water tank, and achieve the effects of facilitating equipment maintenance, simplifying the overall structure, and optimizing the internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

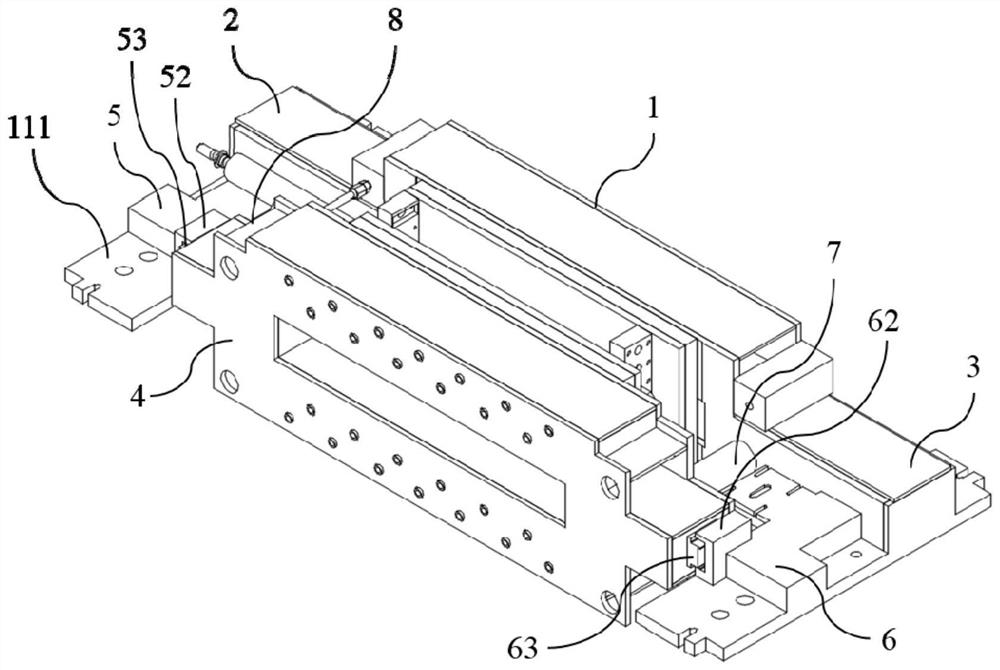

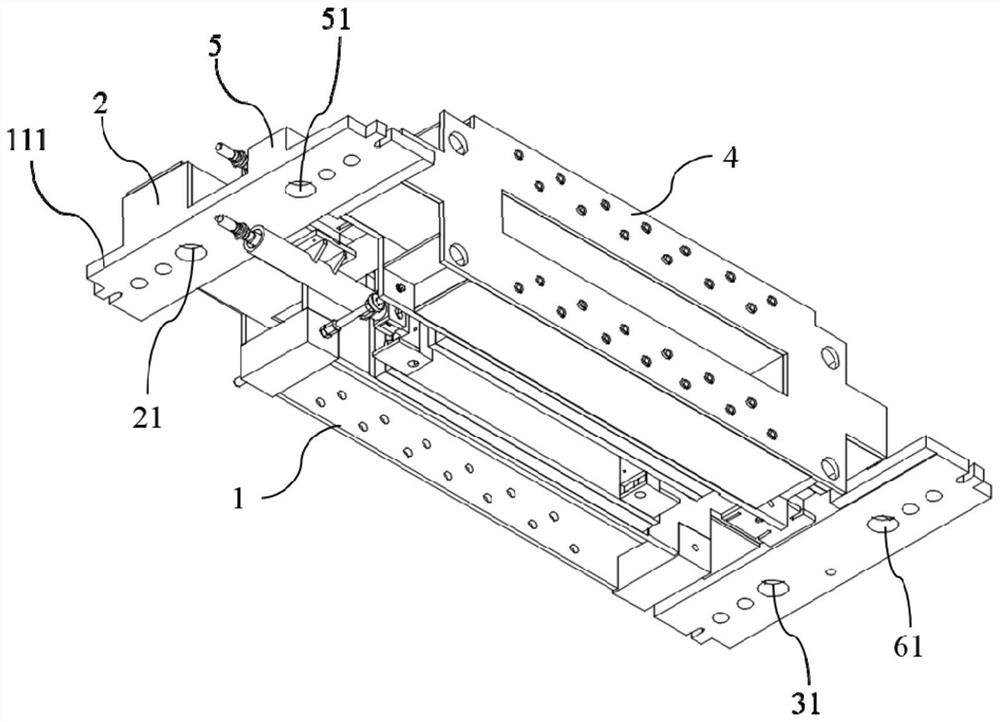

[0038] A new type of slab mold in this embodiment, such as figure 1 As shown in the figure, it includes a fixed plate 111 fixed to the reference, and the upper surface of the fixed plate 111 is fixedly installed with a crystallizer fixed side 1; the processing side of the crystallizer fixed side 1 is movably installed with a crystallizer movable side 4. After the fixed side 1 of the mold is fixed with the reference, install the movable side 4 of the mold. After installation, the whole is transferred to the vibration table for fixing, so as to transform the existing four-piece mold into a two-piece mold, thereby improving the overall strength. and stability, and easy to disassemble; the fixed side 1 of the crystallizer and the movable side 4 of the crystallizer are connected through the water inlet pipe 7 and the water outlet pipe 8 arranged symmetrically on the left and right; the left and right ends of the crystallizer fixed side 1 are respectively Unicom is provided with a f...

Embodiment 2

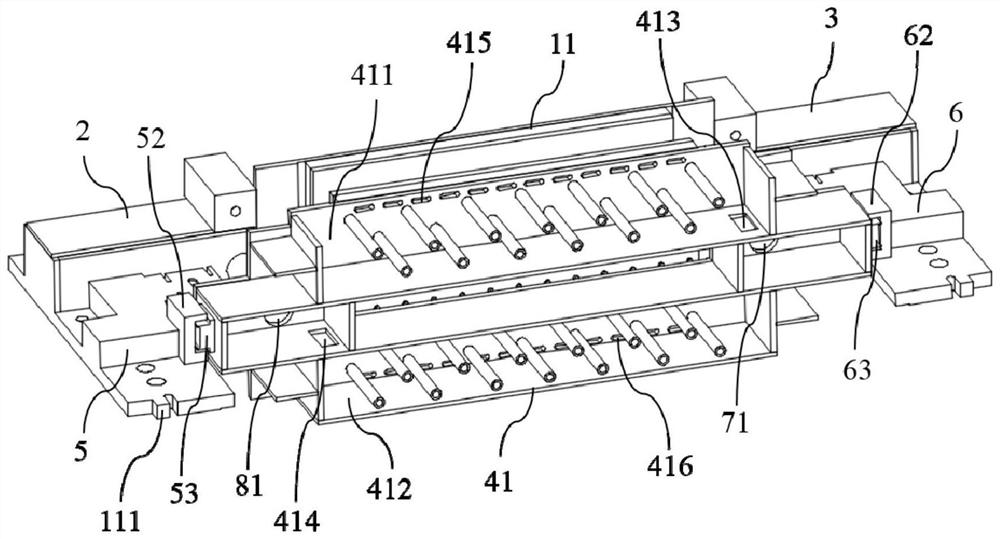

[0041] A new type of slab crystallizer in this embodiment, the basic structure is the same as that in Embodiment 1, and the differences and improvements are as follows: Figures 4 to 7 As shown, the crystallizer fixed side 1 includes a fixed frame body, the crystallizer fixed side 1 includes a fixed frame body 11, and the fixed frame body 11 includes an upper water tank 1101 of the fixed frame body and a lower part of the fixed frame body arranged at intervals up and down The water tank 1102, the spaced area between the upper water tank 1101 of the fixed frame body and the lower water tank 1102 of the fixed frame body is provided with a fixed frame body water outlet 1105 and a fixed frame body water inlet 1106 on the left and right. The side water inlet box 3 is communicated with the fixed frame body 11 through the fixed frame body water inlet 1106 and the fixed frame body water outlet 1105 respectively; the fixed side water inlet box 2 is connected with the fixed plate 111. A ...

Embodiment 3

[0044] A new type of slab crystallizer in this embodiment, the basic structure is the same as that in Embodiment 2, and the differences and improvements are as follows: Figure 4 , 7 As shown, the upper surface of the lower water tank 1102 of the fixed frame body is vertically opened with a lower water tank water inlet I1104 near the water inlet II1106 of the fixed frame body; There is a water outlet I1103 in the upper water tank.

[0045] In this embodiment, the cooling water is discharged into the fixed frame body 11 through the fixed frame body water inlet II1106 through the fixed side water inlet tank 2, and the cooling water enters the lower water tank 1102 of the fixed frame body through the lower water tank water inlet I1104, and the cooling water flows from The lower water tank 1102 of the fixed frame body flows to the copper plate I13 to cool it. The cooling water flows into the upper water tank 1101 of the fixed frame body from above through the gap between the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com