Method for preparing gold-palladium nano-alloy by using protein assembly

A nano-alloy and protein technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of uncontrollable particle size of gold-palladium nano-alloy, unenvironmental technology, high cost, etc., and achieve uniformity Good performance, low cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1 (Preparation of gold-palladium nano-alloys from hemoglobin crystals)

[0062] The first step is the preparation of hemoglobin crystals.

[0063] 1) Mix the hemoglobin solution and the crystallizing agent solution at a ratio of 1:1 to obtain a hemoglobin crystallizing solution.

[0064] The crystallizing agent solution is: 20% polyethylene glycol, 0.2M succinic acid, pH 7.0.

[0065] 2) The hemoglobin crystallisation solution was allowed to stand at 20°C for 1 to 3 days.

[0066] 3) Collect hemoglobin crystals by centrifugation and resuspend the hemoglobin crystals with a crystallizing agent solution to obtain a hemoglobin crystal suspension.

[0067] 4) Mix the hemoglobin crystal suspension with the glutaraldehyde solution to obtain cross-linked hemoglobin crystals.

[0068] 5) Wash the hemoglobin crystals with deionized water and freeze-dry to obtain the final cross-linked hemoglobin crystals.

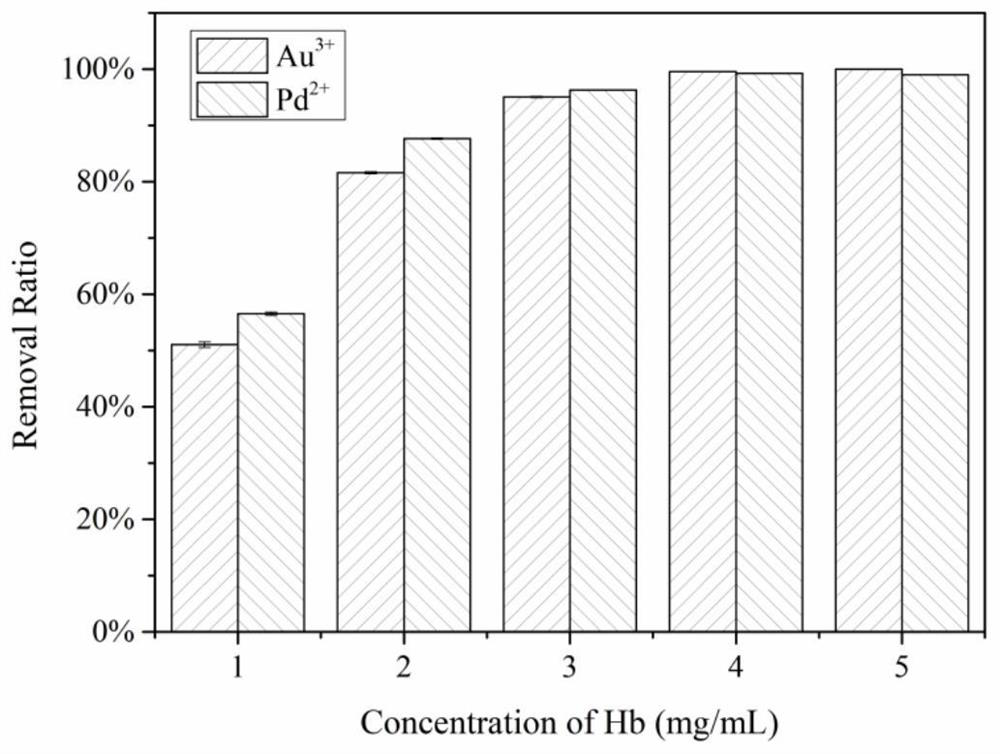

[0069] Step 2, adding the hemoglobin crystals into deionized w...

Embodiment 2

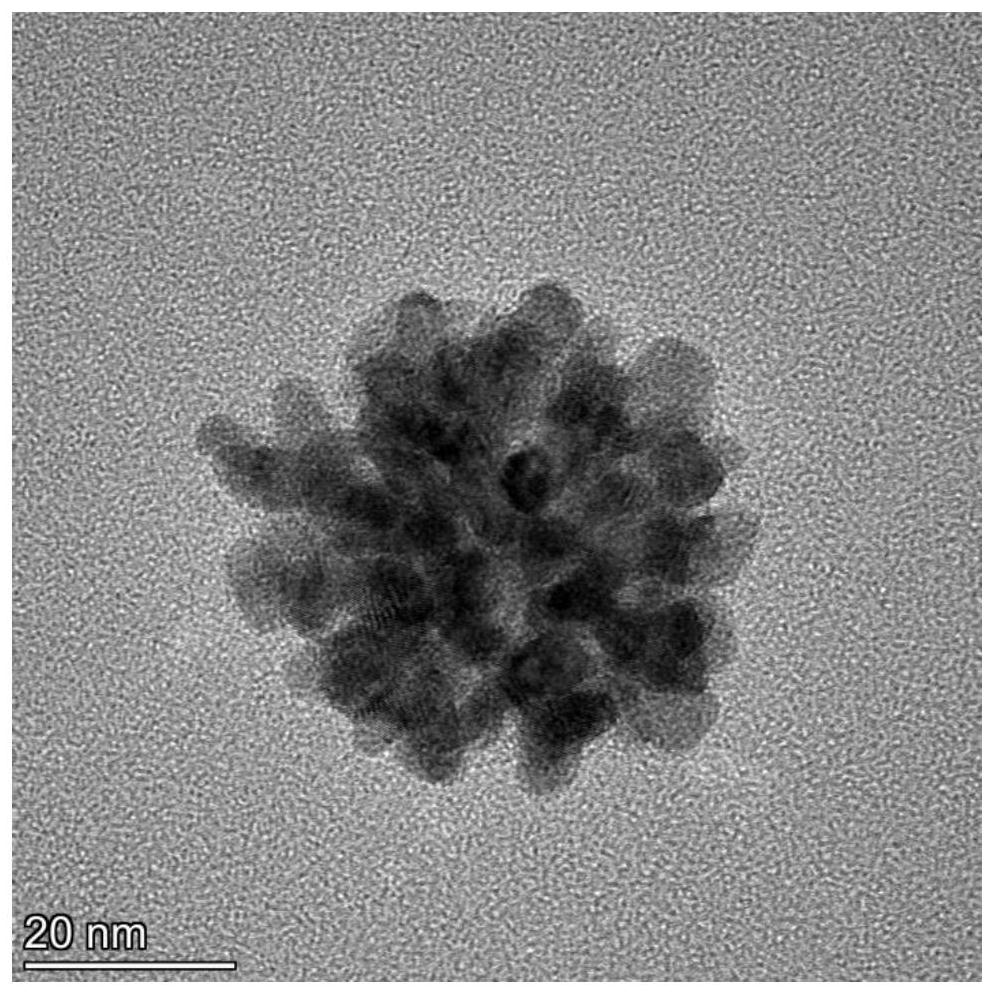

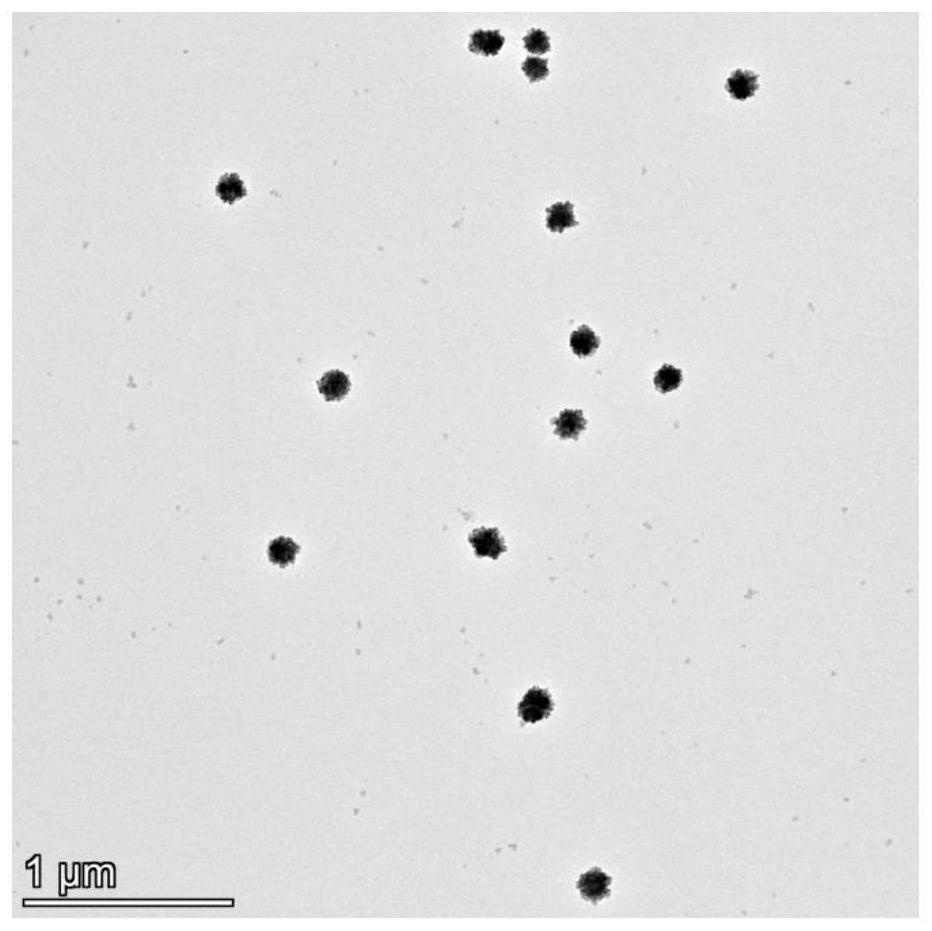

[0085] Example 2 (Preparation of gold-palladium nano-alloy by hemoglobin assembly)

[0086] Step 1, preparation of hemoglobin assembly.

[0087] 1) Mix the hemoglobin solution and the precipitant solution at a ratio of 1:1 to obtain a hemoglobin assembly solution.

[0088] The precipitant solution is: 20% polyethylene glycol, pH 7.0.

[0089] 2) The hemoglobin assembly solution was allowed to stand at 20°C for 1 to 3 days.

[0090] 3) Collect the hemoglobin assembly by centrifugation and resuspend the hemoglobin assembly with a precipitant solution to obtain a hemoglobin assembly suspension.

[0091] 4) Mixing the hemoglobin assembly suspension with the glutaraldehyde solution to obtain a cross-linked hemoglobin assembly.

[0092] 5) Wash the hemoglobin assembly with deionized water, and obtain the final cross-linked hemoglobin assembly after freeze-drying.

[0093] Step 2, adding the hemoglobin assembly into deionized water to disperse evenly to obtain an egg-hemoglobin a...

Embodiment 3

[0107] Example 3 (preparation of gold and palladium nanoalloys from lysozyme crystals)

[0108] The first step is the preparation of lysozyme crystals.

[0109] 1) Mix the lysozyme solution and the crystallizing agent solution at a ratio of 1:1 to obtain a lysozyme crystallization solution.

[0110] The crystallizing agent solution is: 3%-6% NaCl.

[0111] 2) The lysozyme crystallization solution was allowed to stand at 4°C for 1 to 3 days.

[0112] 3) Collect lysozyme crystals by centrifugation and resuspend the lysozyme crystals with a crystallizing agent solution to obtain a lysozyme crystal suspension.

[0113] 4) Mix the lysozyme crystal suspension with the glutaraldehyde solution to obtain cross-linked lysozyme crystals.

[0114] 5) Wash the lysozyme crystals with deionized water and freeze-dry to obtain the final cross-linked lysozyme crystals.

[0115] Step 2: Add the lysozyme crystals into deionized water and disperse them uniformly to obtain a lysozyme crystal su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap