Wood chipping device for artificial board production

A wood-based panel and shaving technology, which is applied in the direction of wood processing equipment, manufacturing tools, and thin wood chip manufacturing, etc., can solve the problems of low efficiency, no real-time adjustment, and the inability to separate the finished product slices from the fines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

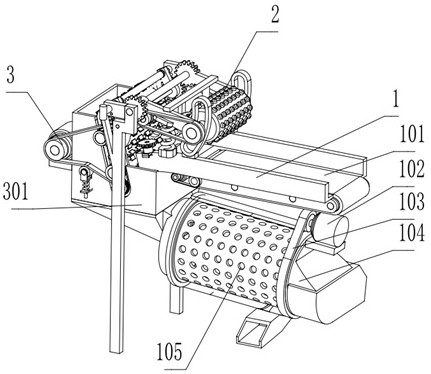

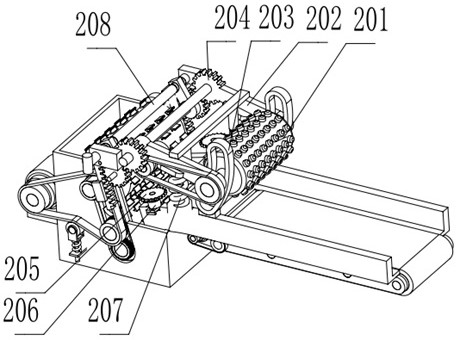

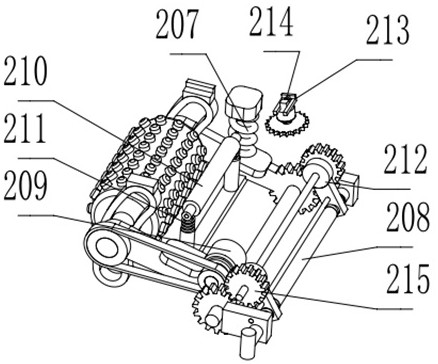

[0019] like figure 1 As shown, the frame 1 is provided with a conveyor belt 101, the bottom of the frame 1 is fixedly connected with an outer cylinder 104, and the outer cylinder 104 is provided with two discharge ports, one of which is used to discharge wood chips, and the other is used to discharge wood chips. For wood chip discharging, the inner cylinder 105 is rotatably installed inside the outer cylinder 104, the screening driving motor 102 is fixedly installed on the outer cylinder 104, and the output shaft of the screening driving motor 102 is connected with a belt structure one 103, and a belt structure one 103 One end of the frame 1 is connected to the inner cylinder 105; one end of the frame 1 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com