Shaftless paper feeding and unwinding device

A technology of unwinding device and paper roll, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc. It can solve the problems of unreasonable paper design, unstable paper tension, and long equipment downtime, etc., and achieves a solution The equipment is shut down for a long time, the installation is quick and convenient, and the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

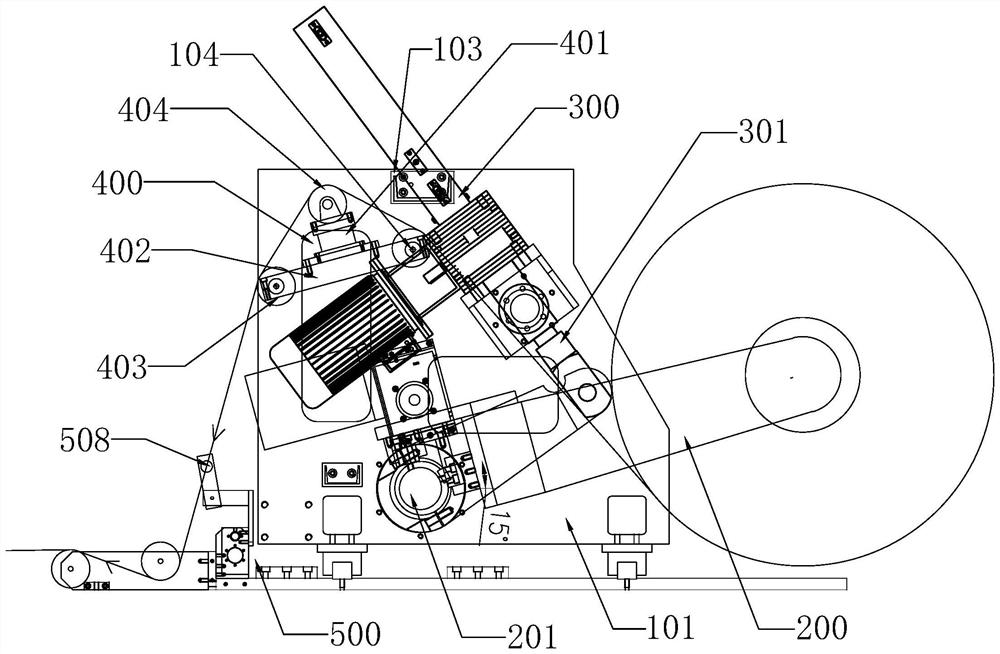

[0025] The shaftless paper unwinding device of the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

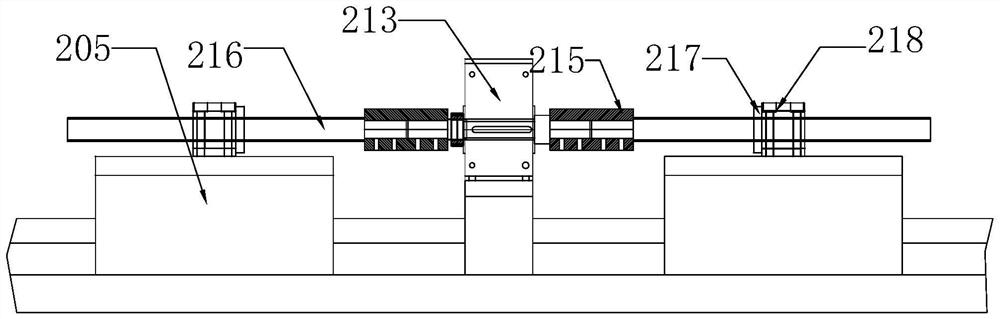

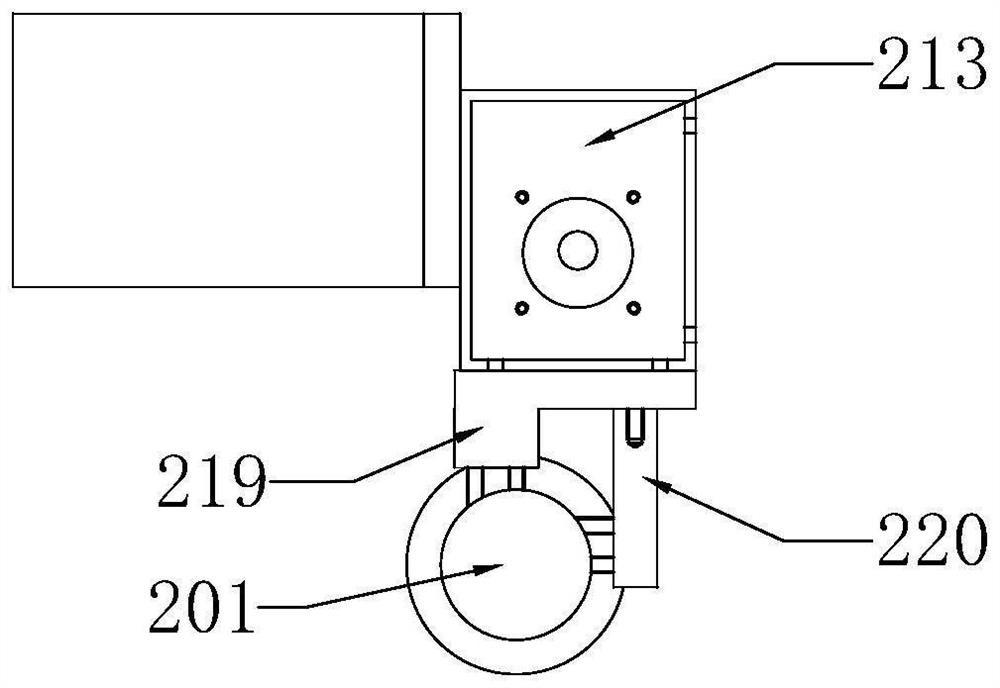

[0026] As shown in the figure, the shaftless paper unwinding device of the present invention includes a paper feeding mechanism 200, a lifting mechanism 300 for driving the lifting and lowering of the paper feeding mechanism 200, and a tension control mechanism 400 for controlling the tension of the paper. It can be seen from the figure, The paper feeding mechanism 200 includes a pair of paper roll swing arms 205 installed on one main shaft 201, and two clamping devices respectively installed on the two paper roll swing arms 205 for adjusting one of the pair of paper roll swing arms 205. The swing arm adjusting device for the distance and the brake 206 installed on the paper roll swing arm 205 for braking the clamping device, wherein the main shaft 201 is installed on the two wall panels through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com