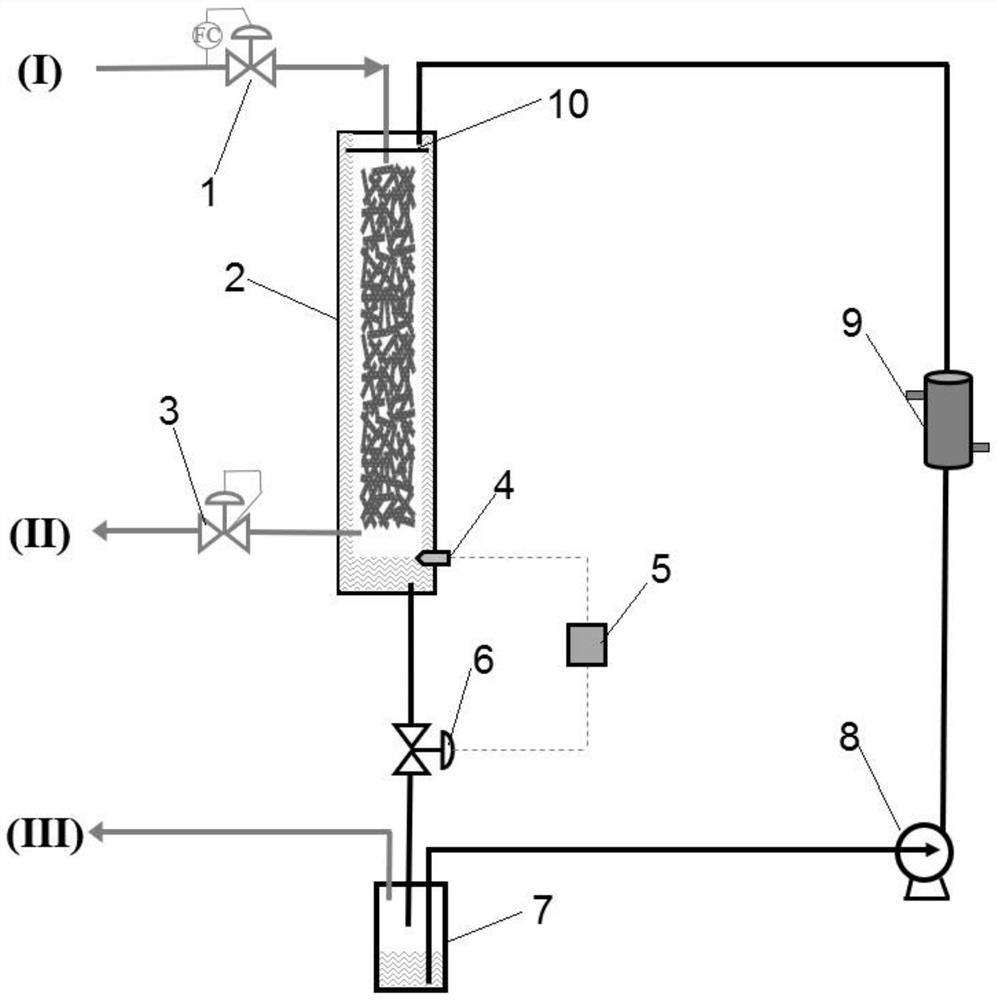

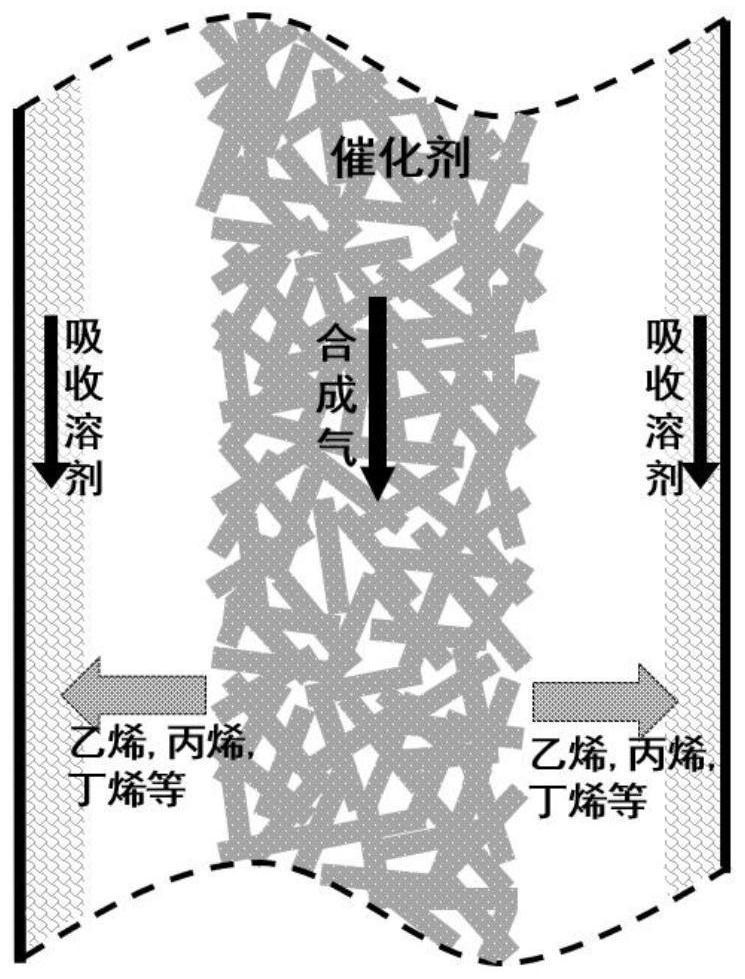

Method for preparing olefin from synthesis gas and reaction and separation integrated reaction device

A reaction device and synthesis gas technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of many types of components, content of difficult-to-separate components, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] The NaSFe@NCNC catalyst was prepared according to the method described in Example 6 of Patent CN111821976A. 1.0 g of the catalyst was weighed, 8.0 g of aluminum hydroxide powder, 1.5 g of polyvinyl alcohol and 8.5 mL of water were added. After heating to 90 °C, the materials were mixed uniformly and cooled. Then put it into a catalyst extruder, extrude clover-shaped particles with a diameter of 2mm and a length of 5-10mm, dry it in a blast drying oven at 100 °C for 4 hours, and then put it into a tube furnace, and heat it up to 10 °C / min under nitrogen protection. After calcination at 500°C for 6 hours, the catalyst was naturally cooled to obtain the desired shaped catalyst.

[0113] Select a stainless steel mesh with a wire diameter of 12 wires and a mesh size of 25 meshes. The stainless steel mesh is sealed, and then the stainless steel cage is inserted into the closed reaction vessel of a circular stainless steel tube with an inner diameter of 12 mm and a length of 5...

Embodiment 2

[0116] According to the method described in Example 5 of patent CN111821976, the nonahydrate ferric nitrate was replaced with equimolar cobalt nitrate hexahydrate, and the anhydrous potassium nitrate was replaced with equimolar anhydrous sodium nitrate, and the cobalt nanoparticles were prepared with a limit threshold of nitrogen. The catalyst in the doped carbon nanocages (marked as NaCo@NCNC), weighed 1.0 g of NaCo@NCNC catalyst, added 8.0 g of aluminum hydroxide powder, 1.5 g of polyvinyl alcohol and 8.5 mL of water, heated to 90 °C and mixed the materials After cooling, put it into a catalyst extruder to extrude clover-shaped particles with a diameter of 2mm and a length of 5-10mm, dry it in a blast drying oven at 100 °C for 4 hours, and then put it into a tube furnace under nitrogen protection at 10 °C / min The temperature was raised to 500°C for calcination for 6h, and the shaped catalyst was obtained by natural cooling.

[0117] Select a stainless steel mesh with a wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com