Balanced steel structure

A type of steel and balanced technology, applied in the direction of building types, building structures, towers, etc., can solve problems such as hollow bottoms and hidden safety hazards of the building as a whole, and achieve the effect of improving stability and preventing collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

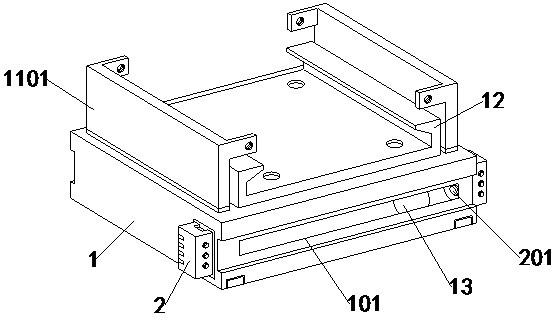

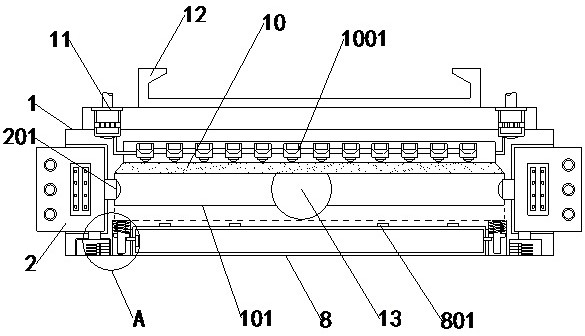

[0028] see Figure 1-Figure 6 , a balanced steel structure, comprising a structural main base 1 and a clip 12 for clamping construction workpieces, and the clip 12 is fixed on the top surface of the structural main base 1;

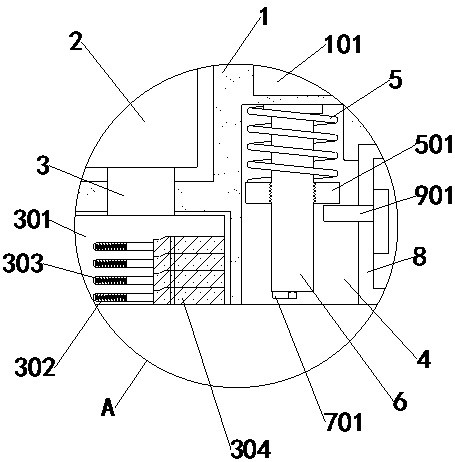

[0029] The bottom surface of the main base 1 of the structure is provided with a reserved groove 4, and the left and right sides of the inner top wall of the reserved groove 4 are fixed with a traction spring 5, and the bottom end of the traction spring 5 is fixed with a sleeve plate 501, and the sleeve plate 501 The center is connected with an auxiliary pipe 6 through a thread, the top of the auxiliary pipe 6 is detachably connected with a cover 601, and a number of release holes 602 are opened on one side of the bottom of the auxiliary pipe 6, and the center of the bottom of the auxiliary pipe 6 is rotatably connected with a rotating shaft 7, And the outer wall of the rotating shaft 7 is fixed with a fan-shaped shielding baffle 701, the shielding baffle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com