Waste residue treatment device for smelting

A treatment device and waste slag technology, which is applied in the field of smelting waste slag treatment devices, can solve the problems of increasing energy consumption and heat escape, and achieve the effects of saving energy consumption, reducing heat overflow, and facilitating centralized collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

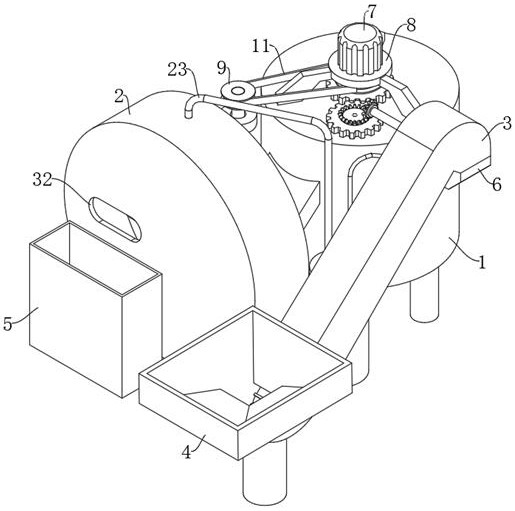

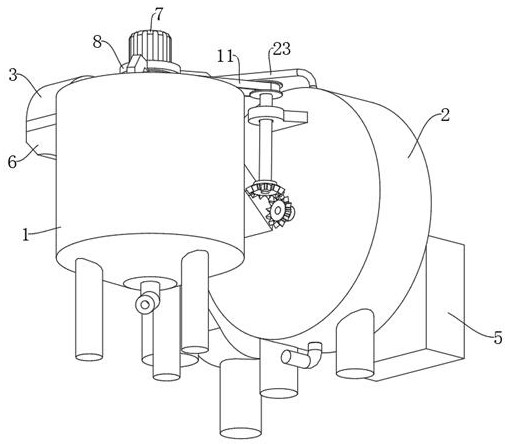

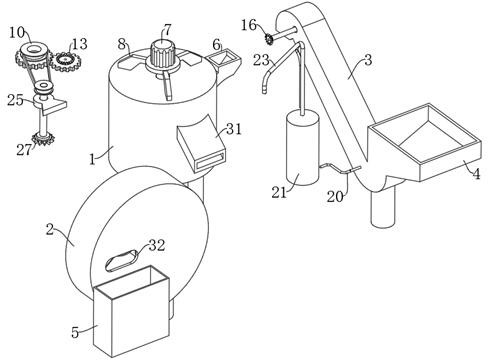

[0039]refer to Figure 1-10 , a waste residue treatment device for smelting, comprising:

[0040] furnace pot 1;

[0041] an output shaft 28, a plurality of output shafts 28 are provided, and the plurality of output shafts 28 are located between the circumferential inner walls of the furnace retort 1;

[0042] Cooling tank 2, the cooling tank 2 is arranged on one side of the furnace tank 1, the side end of the cooling tank 2 is fixedly connected with a slag outlet 31, and the slag outlet 31 is fixedly connected with the circumferential surface of the furnace tank 1;

[0043] Conveying pipe 3, the conveying pipe 3 is arranged on one side of the furnace retort 1, the circumferential surface of the furnace retort 1 is fixedly connected with a feeding port 6, and one end of the conveying pipe 3 is connected with the feeding port 6;

[0044] Linkage mechanism, the linkage mechanism is arranged on the top of the furnace tank 1, and the linkage mechanism is respectively connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com