Double-layer sine compensation type time grating angular displacement sensor

A displacement sensor and compensation technology, which is applied in the direction of instruments, measuring devices, and electric devices, can solve the problems of low excitation effect and induction signal strength, affecting the measurement accuracy of the sensor, and the decrease of the uniformity of the induction magnetic field, so as to achieve enhanced induction Magnetic field uniformity, enhanced excitation effect, enhanced effect of induced magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

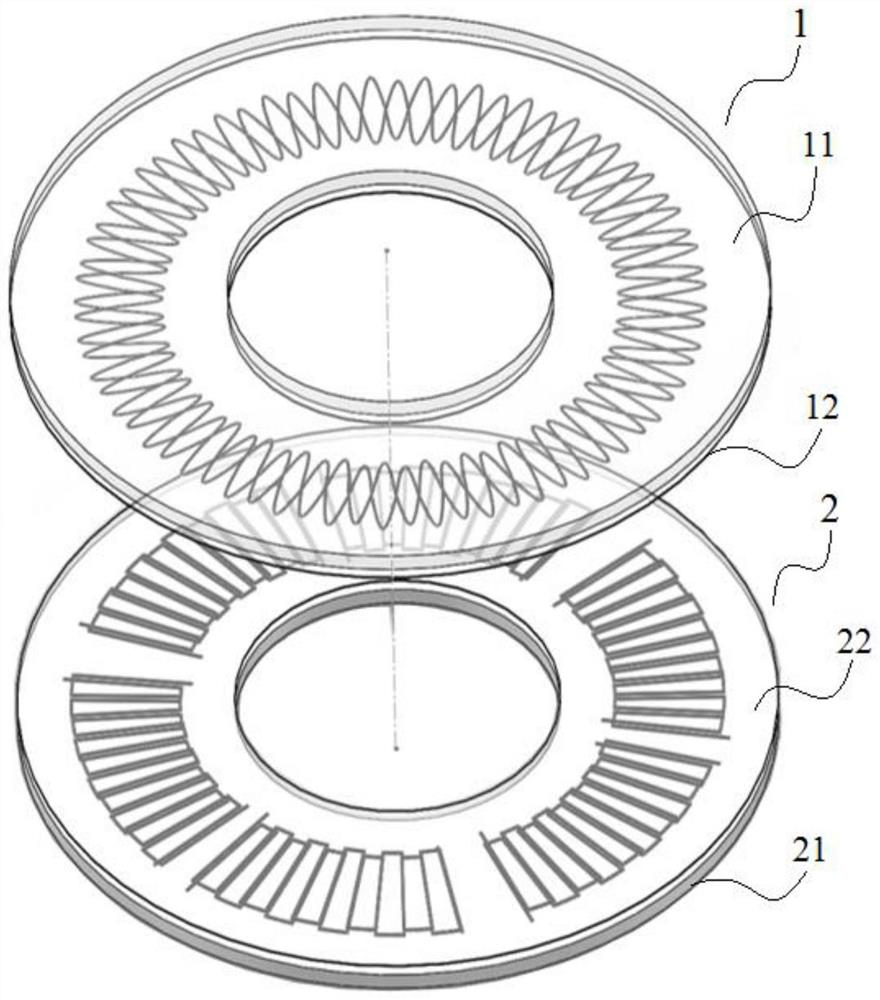

[0024] like Figure 1 to Figure 8 As shown, the double-layer sinusoidal compensation time-grid angular displacement sensor in this embodiment includes a rotor 1 and a stator 2 that is directly opposite and parallel to the rotor 1 and has an air gap (gap) of 0.4 mm.

[0025] like Figure 1 to Figure 5 As shown, the stator 2 includes a stator base 21, an excitation unit disposed on the stator base 21, and a stator insulating layer 22 covering the excitation unit. The stator insulation layer 22 can prevent the excitation unit from being exposed. The thickness of the stator base body 21 is 1 mm, the diameter of the outer circle is 70 mm, the non-magnetic conductive material is used, and the thickness of the stator insulating layer 22 is 0.15 mm.

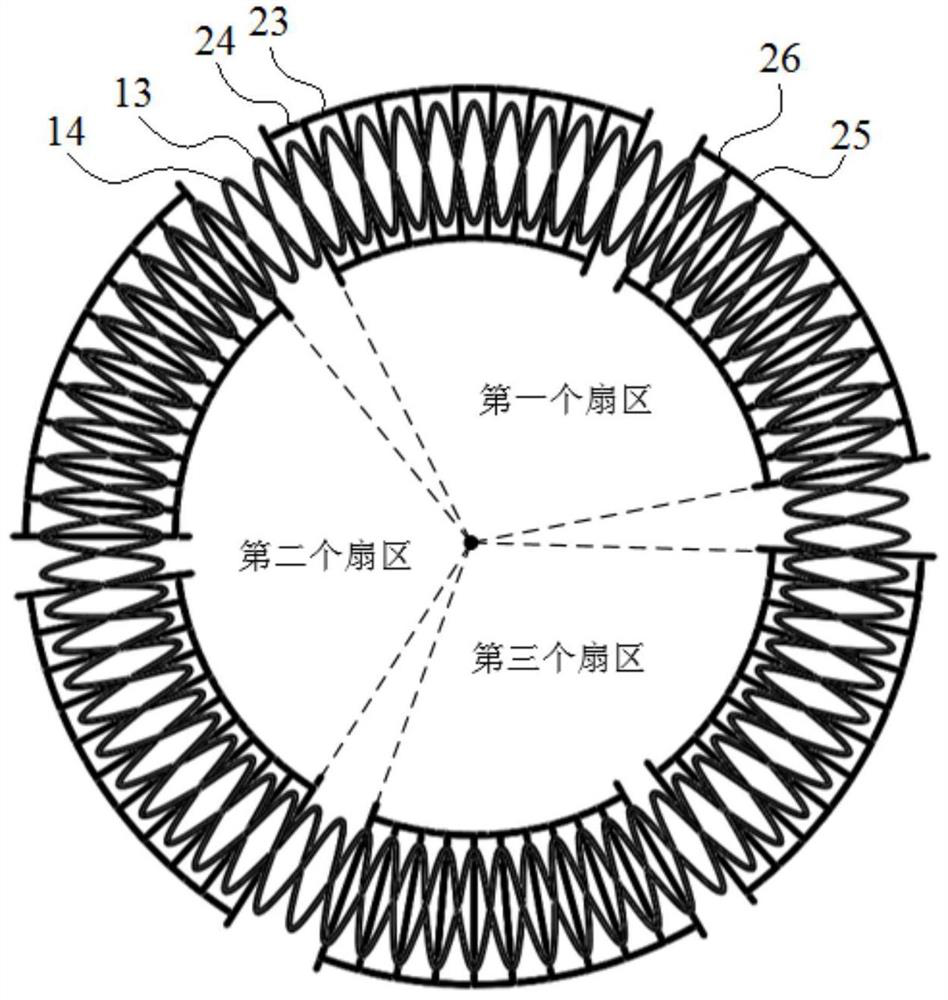

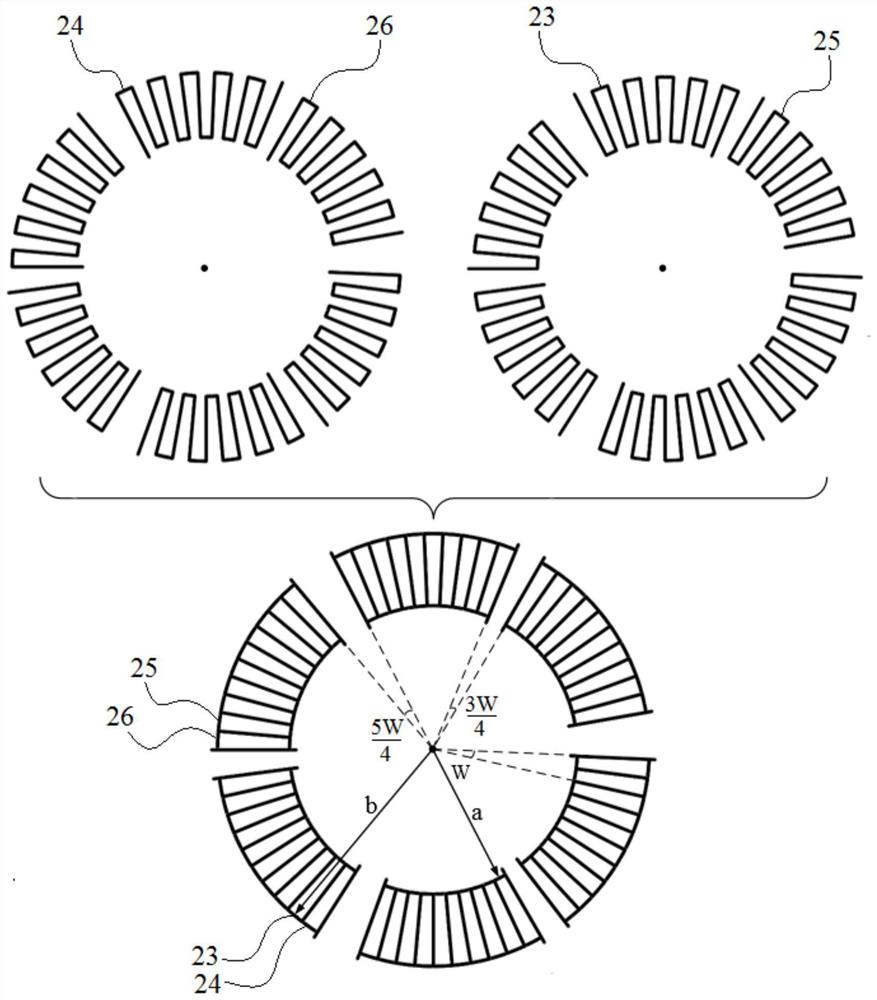

[0026] The excitation unit includes three sectors evenly arranged along the circumferential direction, the central angle opposite each sector is 107.5°, each sector includes a first excitation coil and a second excitation coil, two adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com