Intelligent inspection equipment for workpiece surface electroplating uniformity

A technology for inspection equipment and workpiece surface, applied in the field of inspection equipment for the uniformity of electroplating on the surface of intelligent workpieces, can solve problems such as affecting production efficiency, uneven zinc coating spraying, wasting labor, etc. The effect of reducing distractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

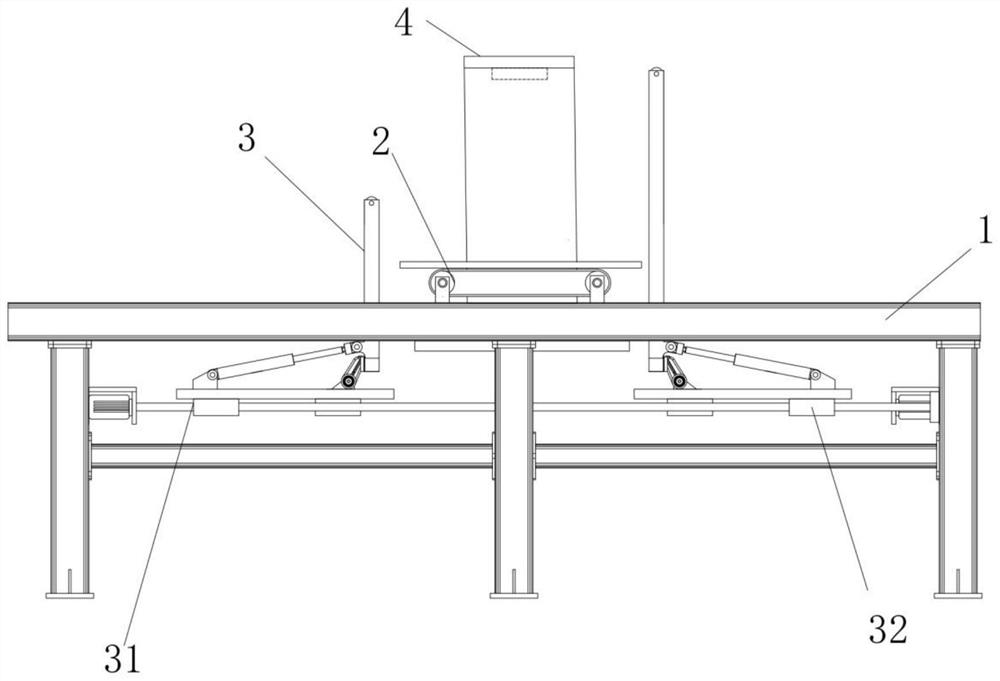

[0034] like figure 1 , figure 2 As shown, an intelligent inspection equipment for the uniformity of electroplating on the surface of a workpiece includes: a frame 1;

[0035] Place the deflection module 2, which is arranged on the frame 1, for placing the detection piece and the auxiliary detection piece for flipping;

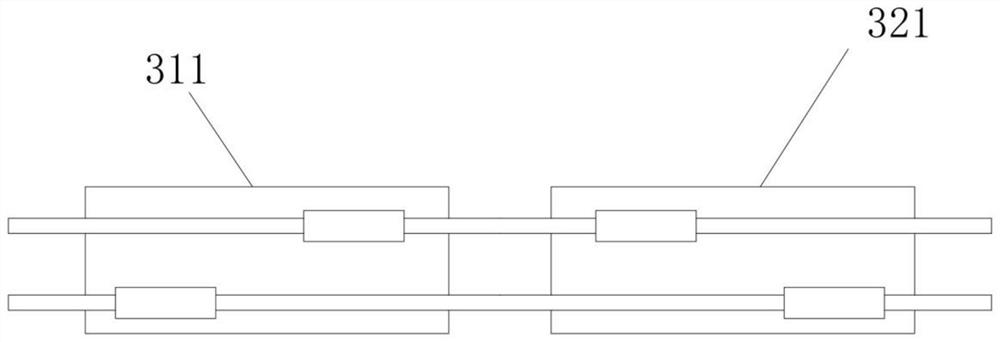

[0036] The movable rod module 3 is arranged on the frame 1 and is used for locking or turning over the detection piece;

[0037] The photographing module 4 is arranged on the rack 1 and is used for photographing and sampling the detection piece placed on the placing module;

[0038] The control module, arranged on the rack 1, is used to send control instructions to other modules and to detect and analyze the images collected by the shooting module 4;

[0039] The placement deflection module 2 includes a mounting frame, a conveyor belt, a driving motor, a driving roller and a driven roller, the mounting frame is arranged on the frame 1, and the driving rolle...

Embodiment 2

[0047] Embodiment 2, this embodiment is a further description of the above-mentioned embodiment. It should be understood that this embodiment includes all the foregoing technical features and further detailed description:

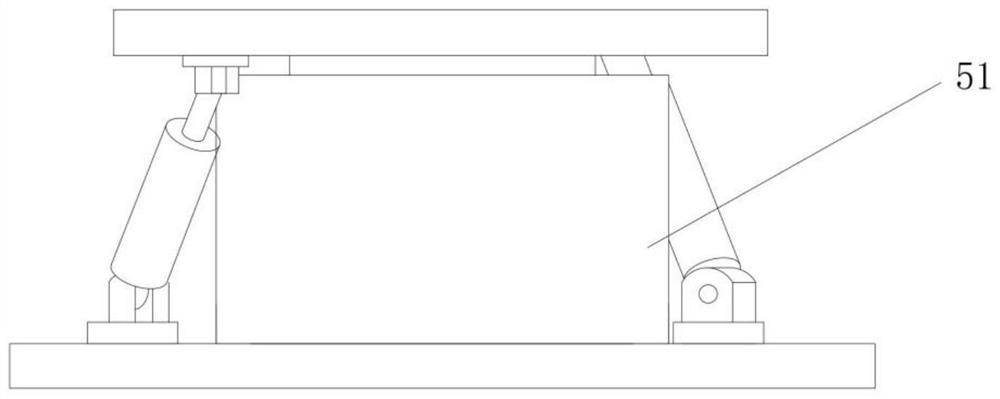

[0048] combine further image 3 , Figure 4 , Figure 5 , Image 6 As shown, the frame 1 is also provided with a blanking mechanism 5. The blanking mechanism 5 includes a rotating unit 51 and a blanking slideway 52. The rotating unit 51 is used to drive the placement deflection module 2 to rotate. The blanking slideway 52 is provided with a roller for the workpiece to be detected to slide down;

[0049] The rotating unit 51 includes a rotating platen, a fixed bottom plate, a supporting fixed seat, a bearing, a first universal ball seat, a second universal ball seat and a third telescopic cylinder, and the fixed bottom plate is fixedly installed on the frame 1, The supporting and fixing base is arranged on the fixed base plate, the bearing is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com