Complete machine variable-dimension simulation performance simulation process control method

A technology of performance and dimension, applied in the direction of design optimization/simulation, geometric CAD, etc., can solve the problems of increasing the cost, cycle and risk of engine development, and achieve the effect of avoiding tediousness and inefficiency and ensuring simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

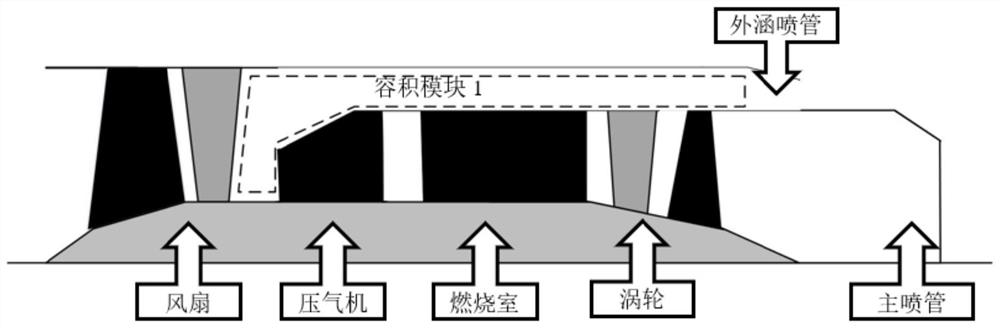

[0097] figure 2 It is a structural diagram of a single-shaft split-exhaust turbofan engine provided by an embodiment of the present invention.

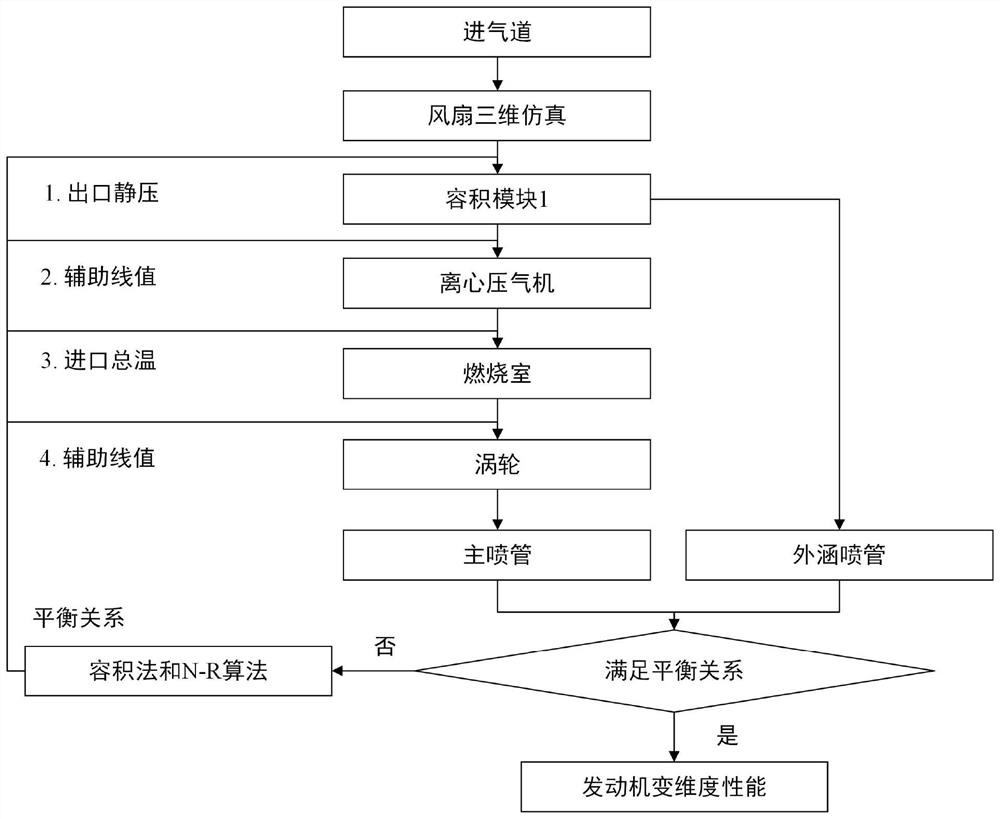

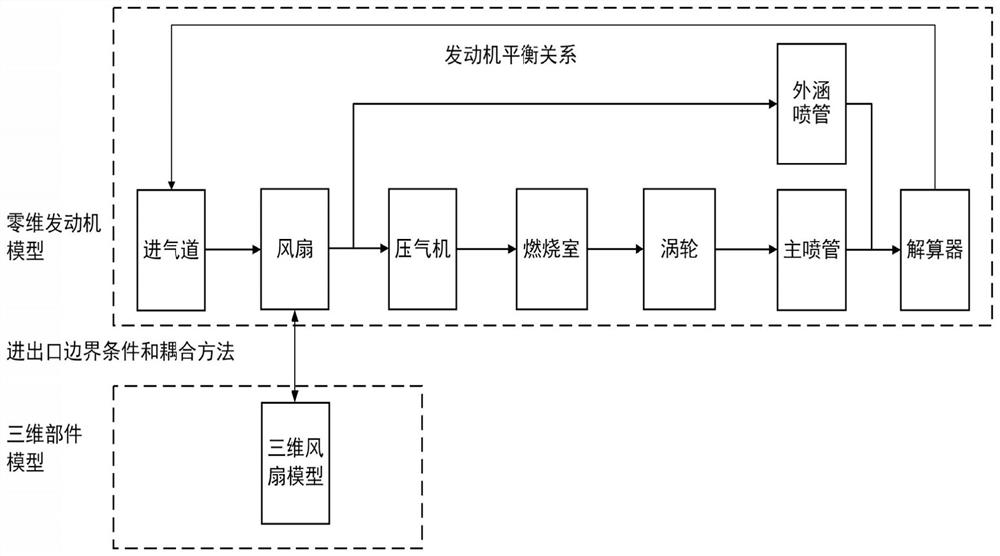

[0098] image 3 It is a frame diagram of the simulation performance simulation flow of the whole machine variable dimension simulation provided by the embodiment of the present invention.

[0099] Step 1: Input engine operating parameters, component performance, and control laws to calculate design points, and determine engine design parameters and key cross-sectional areas as shown in Table 1.

[0100] Table 1. Engine Design Parameters

[0101]

[0102] Figure 4It is the meridian geometry diagram of the engine fan provided by the embodiment of the present invention.

[0103] Figure 5 It is a three-dimensional grid diagram of the engine fan provided by the embodiment of the present invention.

[0104] Step 2: Calculate the boundary conditions of the three-dimensional model of the fan through the zero-dimensional model of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com