Tool for installing rotor with permanent magnet into stator

A technology of rotor loading and permanent magnets, applied in the direction of centering/balancing rotors, etc., can solve the problems of low efficiency, complicated handling and assembly by operators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

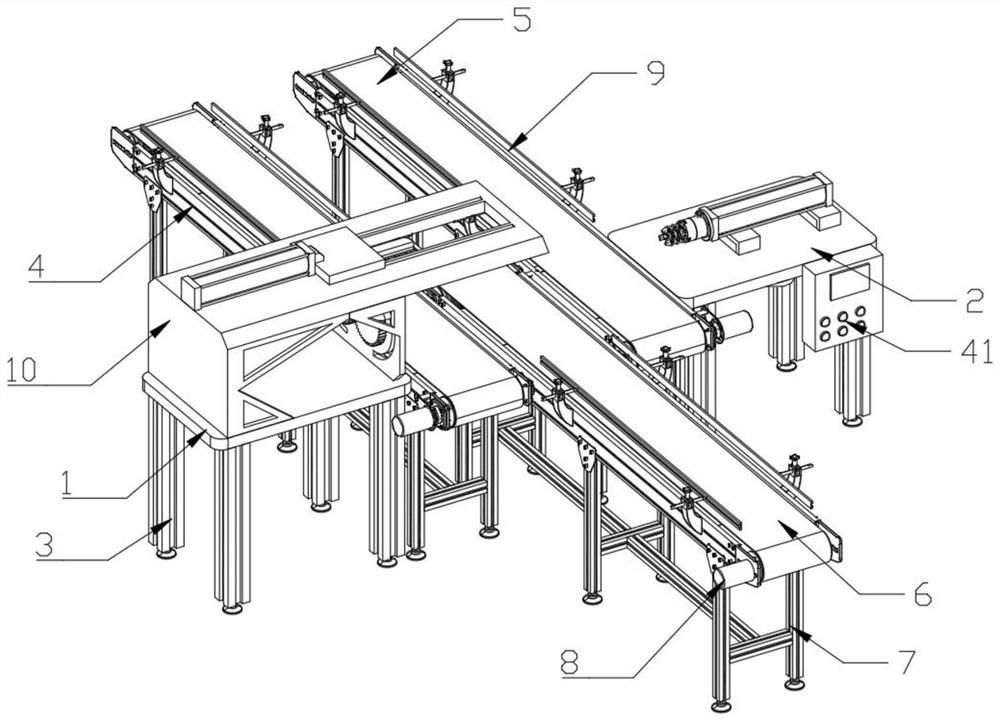

[0028] like Figure 1-Figure 5 As shown, the present invention provides a tool for installing a rotor with a permanent magnet into a stator, including a first operating table 1 and a second operating table 2, and the first operating table 1 and the four parts of the bottom are provided with first support columns 3 , a controller 41 is provided on one side of the front end of the second operating table 2, a casing conveyor belt 4 is provided on one side of the first operating table 1, and a rotor conveyor belt is provided on the side of the second operating table 2 close to the casing conveyor belt 4 5. There is a finished conveyor belt 6 between the casing conveyor belt 4 and the rotor conveyor belt 5. The casing conveyor belt 4, the rotor conveyor belt 5 and the finished product conveyor belt 6 are all provided with a second support column 7 at the bottom. The casing conveyor belt 4. The rotor conveyor belt 5 and the finished product conveyor belt 6 are provided with a first ...

Embodiment 2

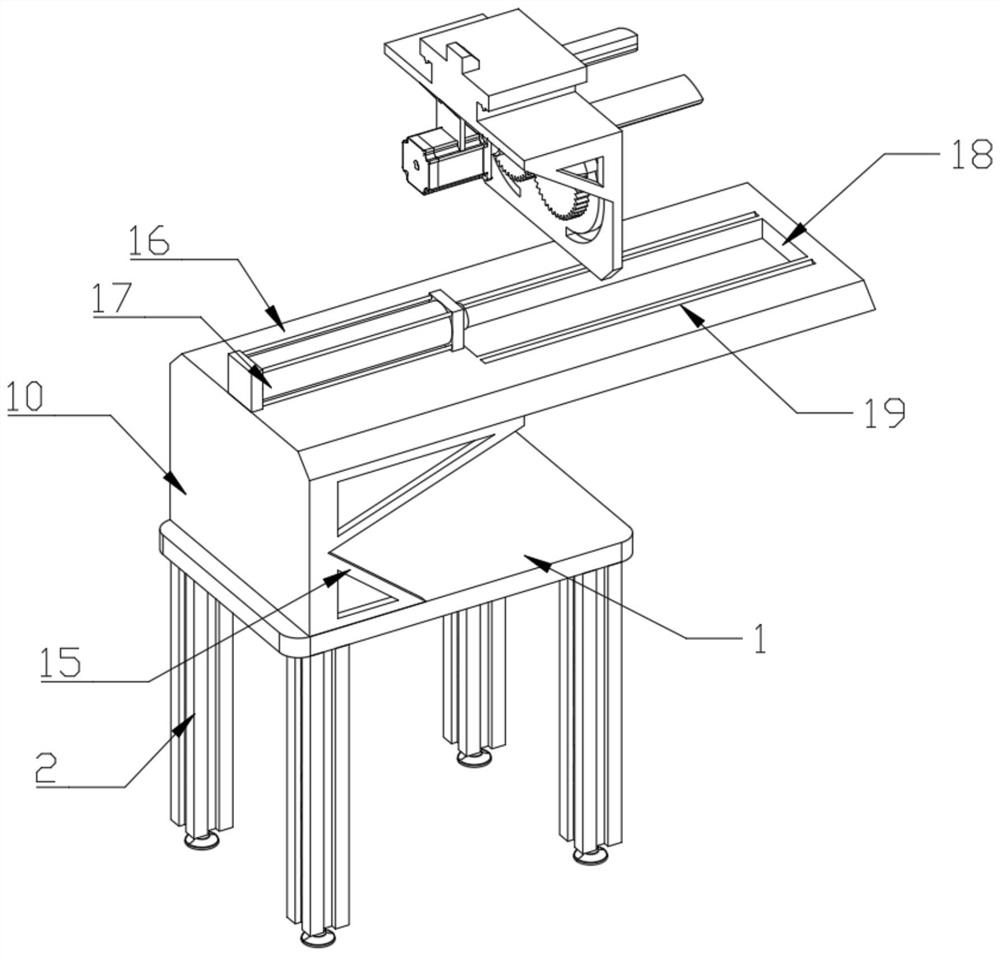

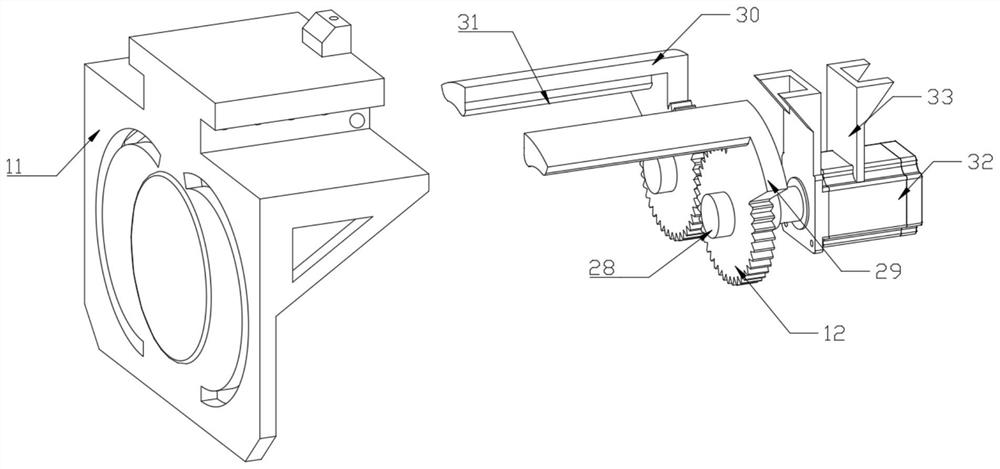

[0030]One side of the first top plate 16 is fixedly installed on the side of the first side plate 10 by welding, and a first side plate 10 is fixedly installed between the first console 1 and the walls of the first top plate 16 . The support plate 15, the first cylinder 17 is fixedly installed on the top side of the first top plate 16, and the first cylinder 17 is connected with the external gas station, and the first top plate 16 is provided with a sliding block in the wall body close to the first cylinder 17 side. 18, the top of the first top plate 16 is provided with a chute 19 at the front and rear ends of the sliding port 18, a second top plate 20 is fixedly installed above one side of the second side plate 11, and one side of the second side plate 11 is connected to the second top plate. 20. A second support plate 21 is symmetrically and fixedly installed on one side of the bottom of the second top plate 20. A T-shaped slider 22 is fixedly installed at the center of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com