Improvements in directionally adjustable blade pivot radial locking for turbine fan hub

A pivoting part, turbine technology, applied in the direction of rotors, mechanical equipment, aircraft parts, etc., can solve problems such as contact wear of inner bushings, and achieve the effect of eliminating wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

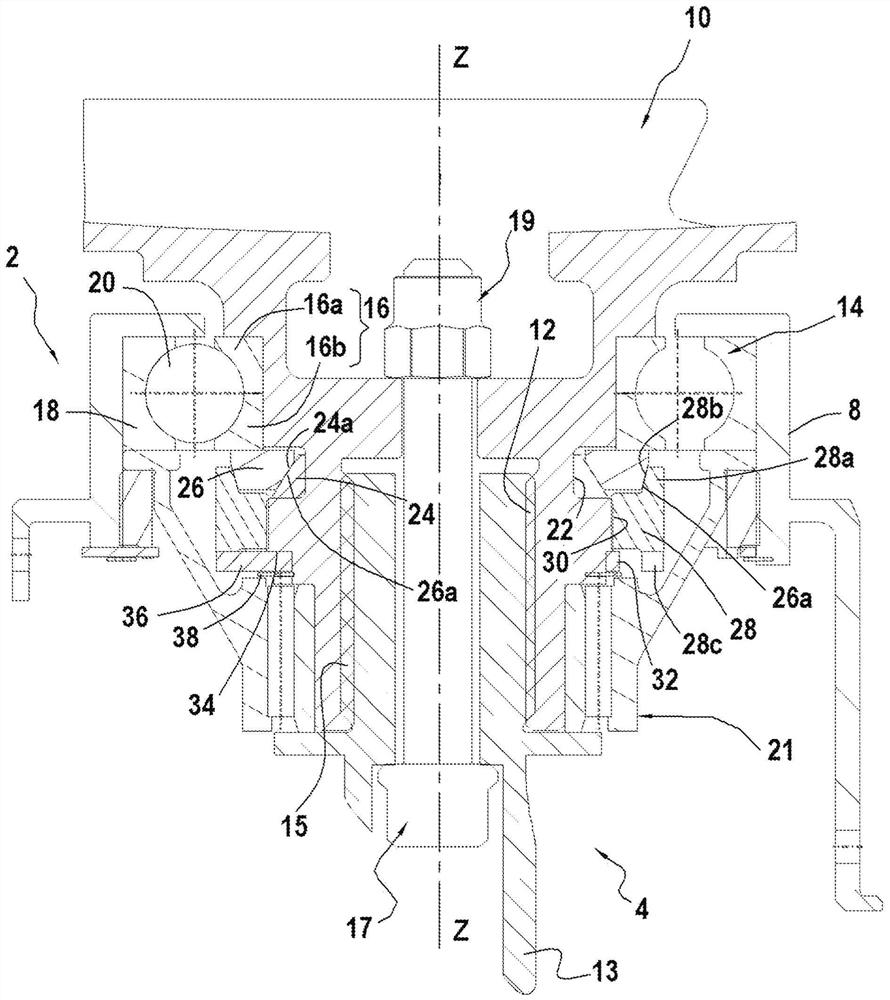

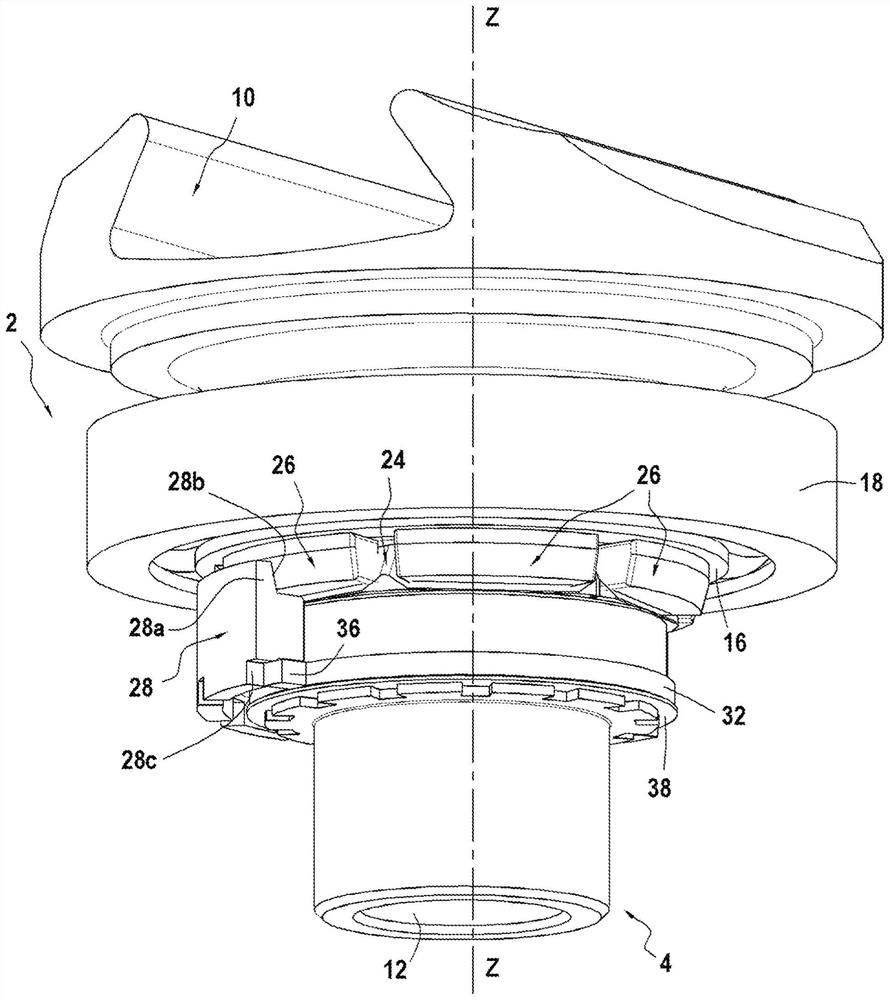

[0041] The present invention is applicable to equipment equipped with at least one ducted fan or non-ducted fan, and whose fan blades (in the case of ducted fans) or propeller blades (in the case of non-ducted fans) are equipped with a pitch setting system any turbine.

[0042] The invention is particularly applicable to turbojets of the type comprising fans with very high bypass ratios (large fan diameters) and very low pressure ratios.

[0043] The architecture of these types of turbojets is well known to those skilled in the art and therefore will not be described in detail here. Briefly, these turbojets include a large diameter ducted fan provided with a system for changing the pitch setting of the fan blades.

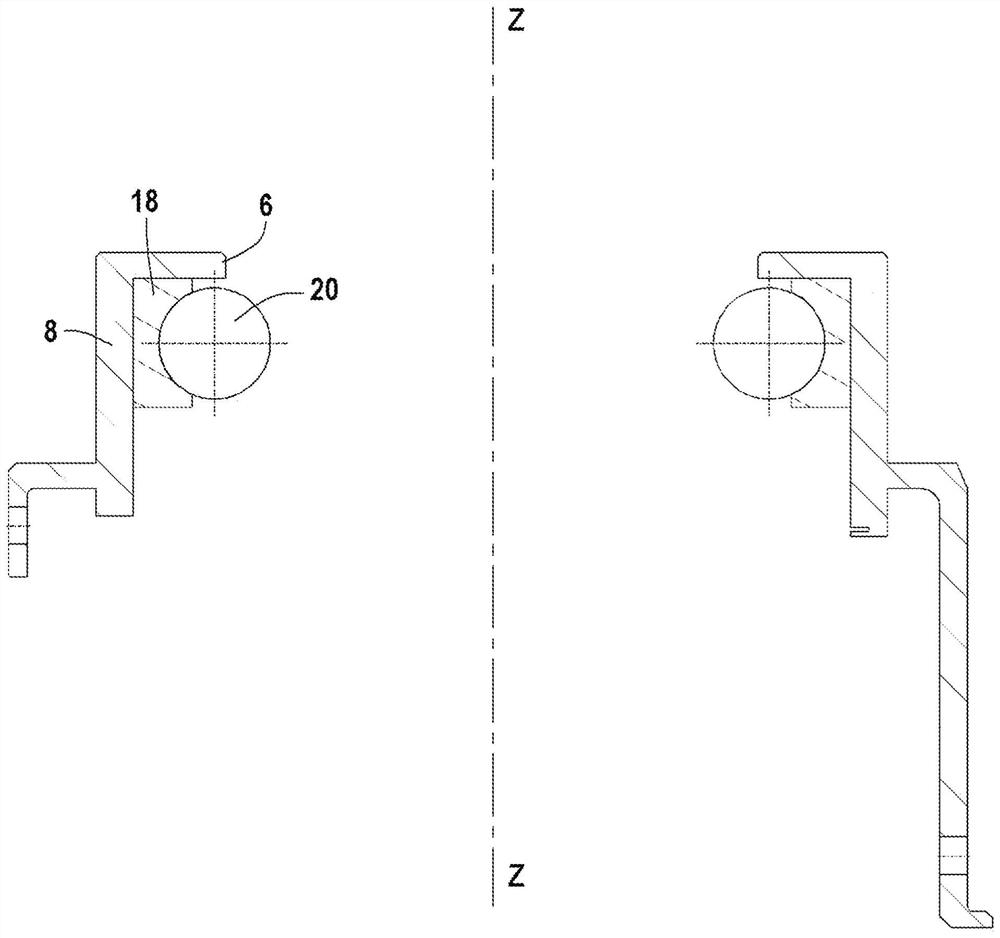

[0044] Such a pitch setting changing system may, for example, include a lever arm (or eccentric) coupled to each vane pivot and pivotally actuated by a cylinder.

[0045] More specifically, the function of the pivot of each blade is to ensure that the fan blade r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com