Stamping die of automobile function module

A stamping die and functional technology, which is applied in the field of stamping dies of automotive functional modules, can solve problems such as difficult stamping of multiple workbenches, inconvenient overall use, and inability to effectively adjust the height, so as to achieve disassembly and assembly, and overall Easy to use and high stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

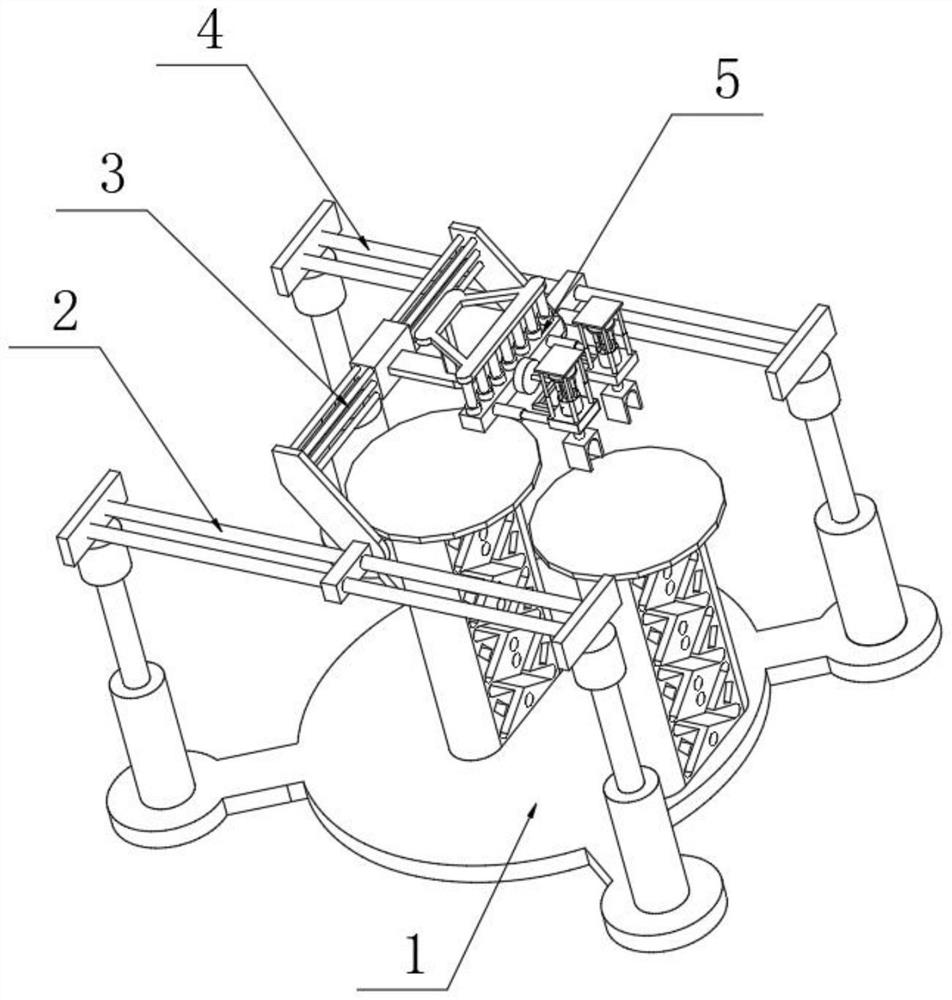

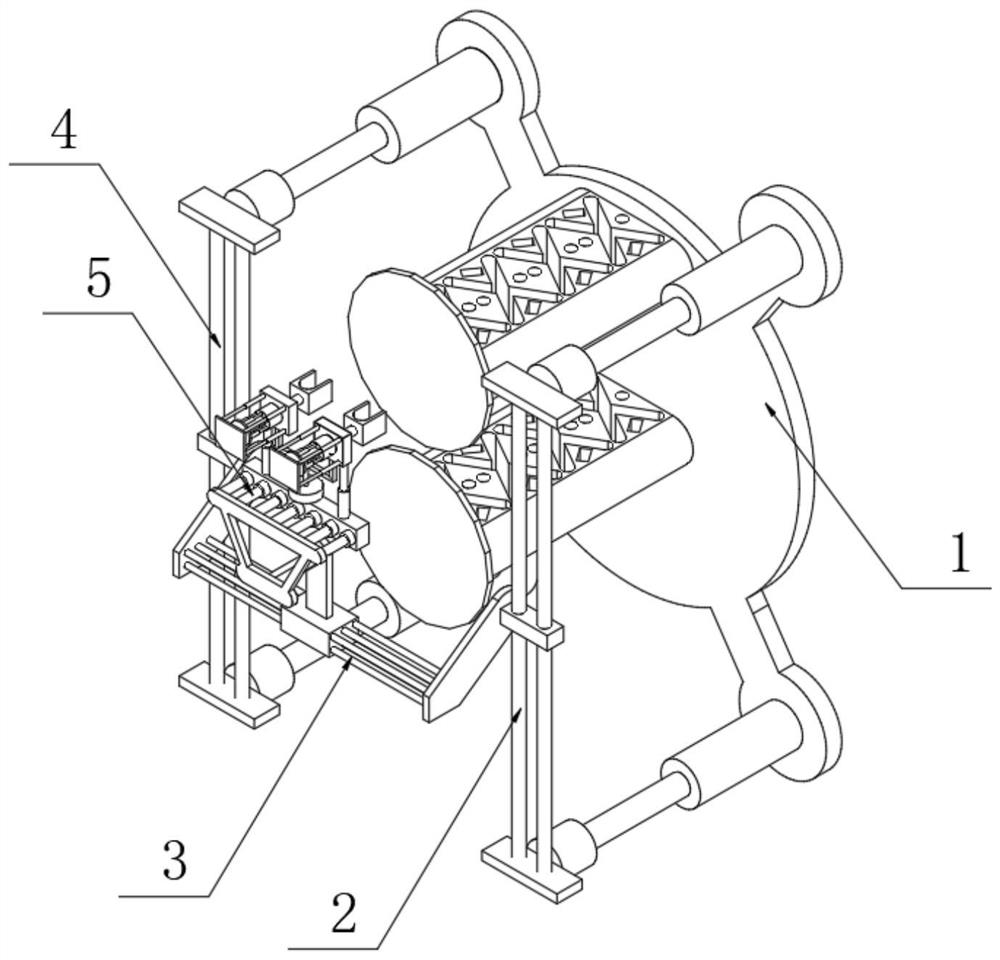

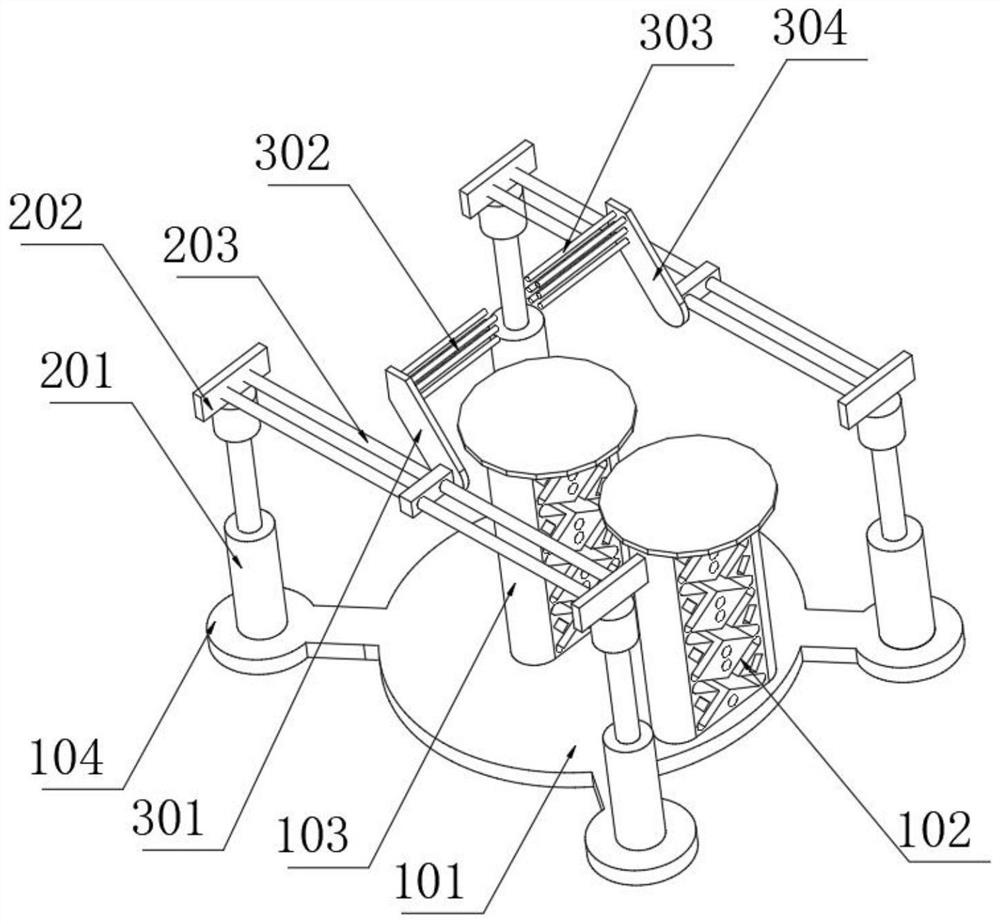

[0025] see Figure 1-6 , In the embodiment of the present invention, a stamping die for an automotive functional module includes a support base 1, a support bottom plate 101, a retractor 201, a connecting block 305 and a support frame 501, and the top surface of the support base 1 is fixedly connected with a side telescopic The frame A2 and the side telescopic frame B4 can change the stamping method of the entire automobile functional module stamping process. By changing the traditional relatively simple stamping method, the position can be moved, the stamping die can be moved easily, and the overall equipment can be easily adjusted. , the side telescopic frame A2 and the side telescopic frame B4 can play a supporting role. The outer walls of the side telescopic frame A2 and the side telescopic frame B4 are sleeved with a mobile connector 3, and one side of the mobile connector 3 is fixed. The punch 5 is connected, the peripheral outer wall of the support base 101 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com