Rapid shoelace tying device

A fast technology for tying shoelaces, applied in the field of shoes, can solve the problems of complex structure, affecting consumer experience, and inability to tighten, etc., to achieve the effect of simple working principle, improved user experience, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

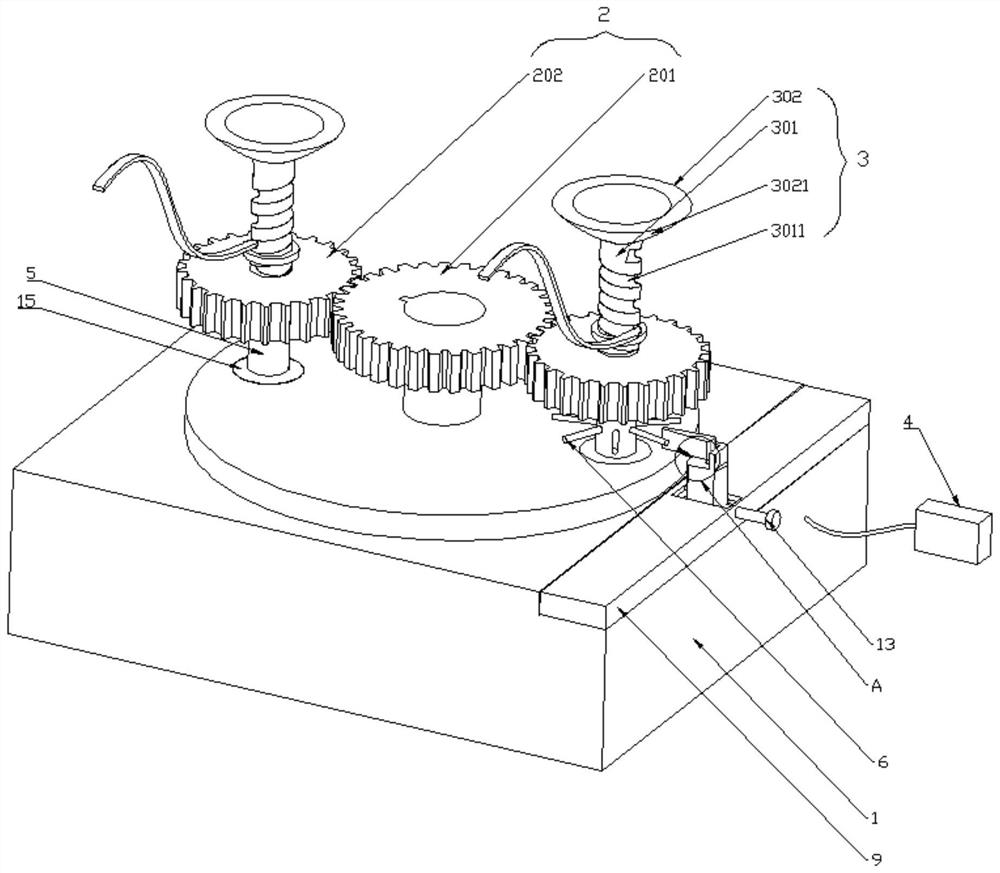

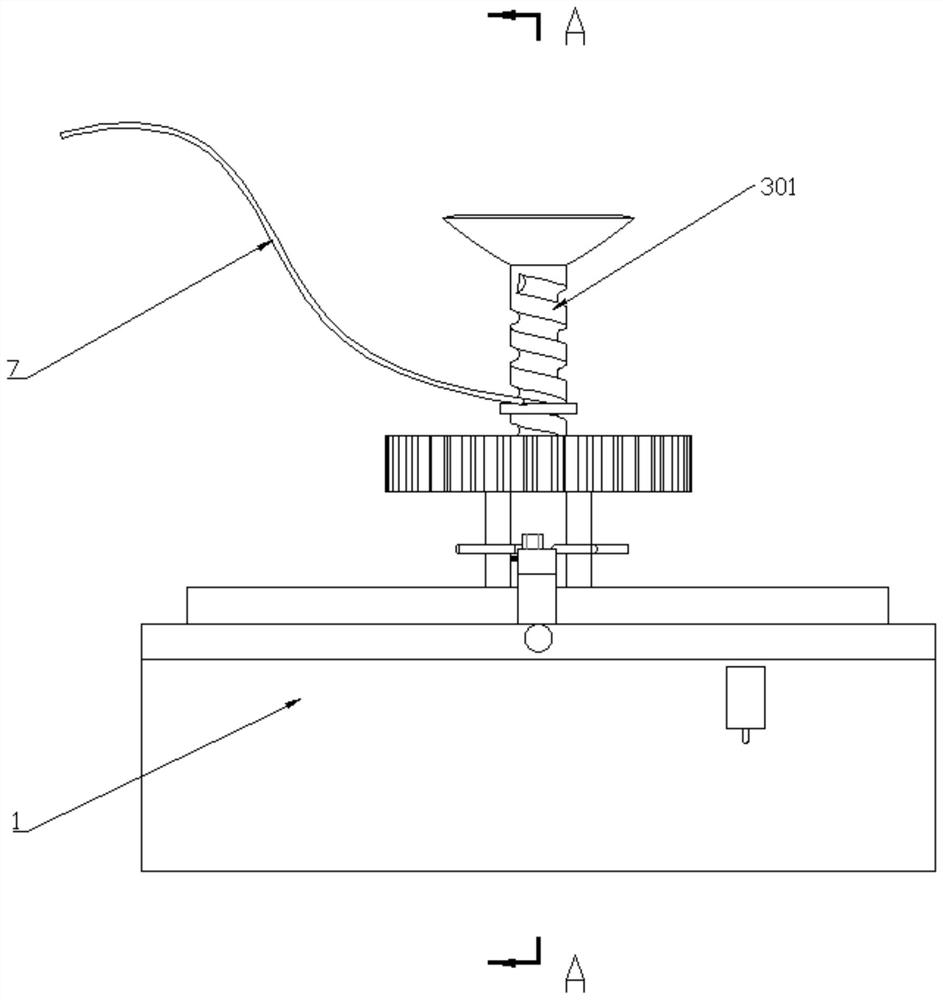

[0026] Below in conjunction with specific embodiments, the present invention is further described, such as Figures 1 to 6 As shown, a fast shoelacing device includes a shoelace tensioning mechanism arranged on the sole of the shoe, and the shoelace tensioning mechanism includes a micro reduction motor 1, a gear set 2, a shoelace winding rod 3, a resisting part, and a micro reduction motor. 1 Electrically connected control switch 4.

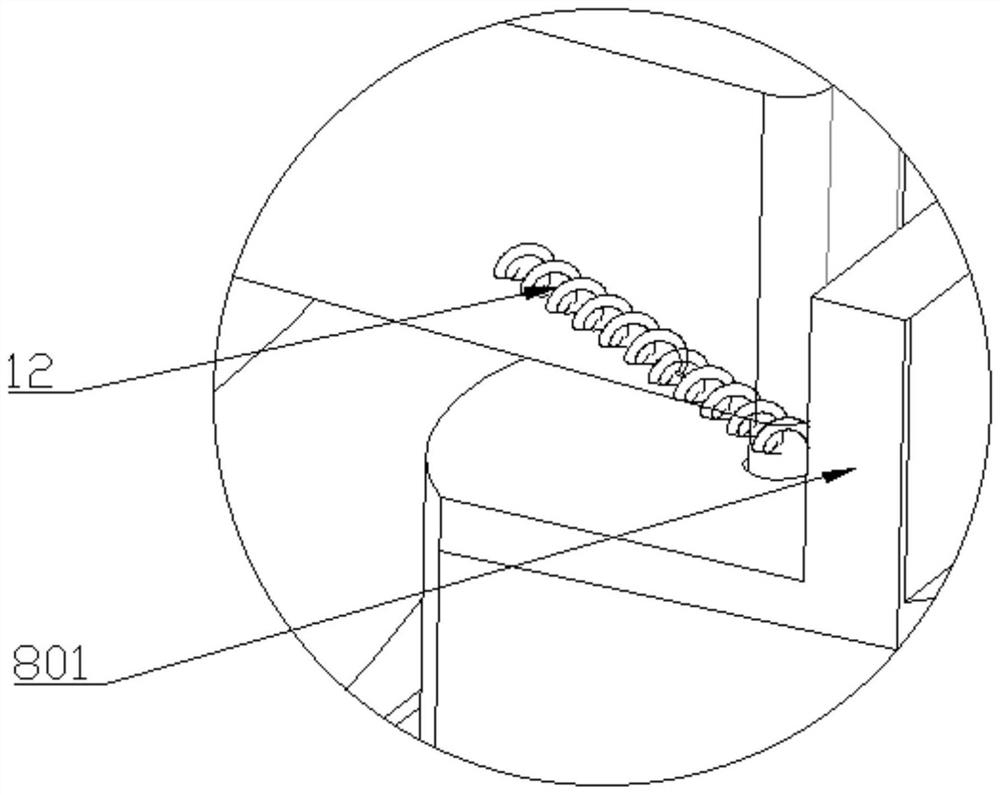

[0027] The gear set 2 includes a driving gear 201 and a driven gear 202 respectively meshing with the two sides of the driving gear 201. The driving gear 201 is connected with the output shaft of the micro reduction motor 1, and the two driven gears 202 are respectively rotated through the rotating shaft 5 arranged vertically. It is arranged on the casing of the micro gear motor 1, and the casing of the micro gear motor 1 is provided with two circular grooves 101. The circular grooves 101 are respectively provided with bearings 15, and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com