Aerosol generator and system

An aerosol generator and aerosol generation technology, applied in inhalers, atomizers for treatment, etc., can solve the problems of difficult atomization and utilization of substrates, long preheating time, waste of substrates, etc. Effects of speed and substrate utilization, reduction of by-products, prevention of overheating or insufficient heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

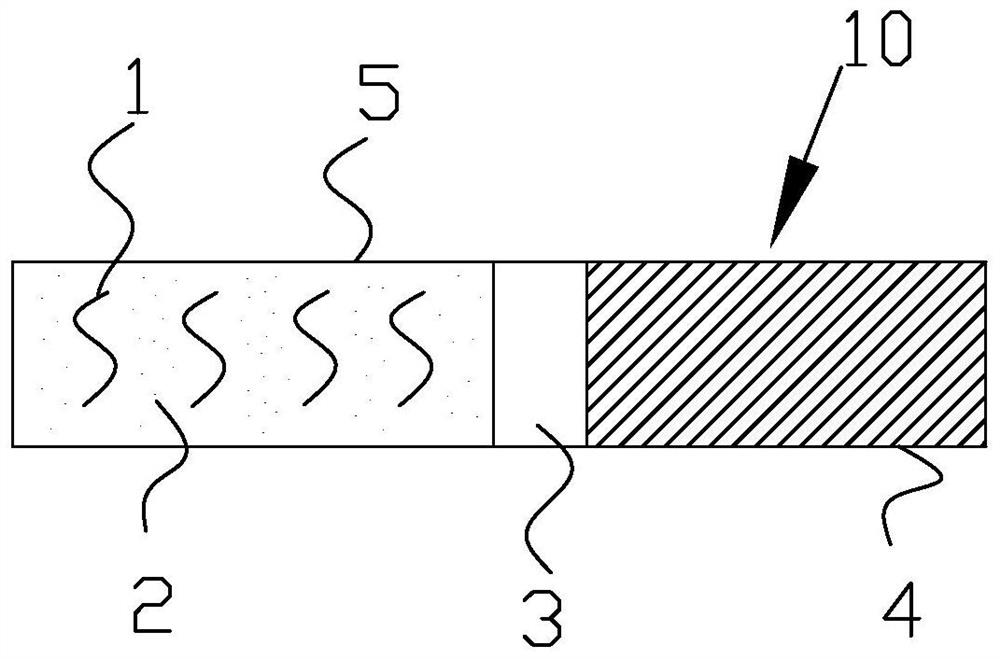

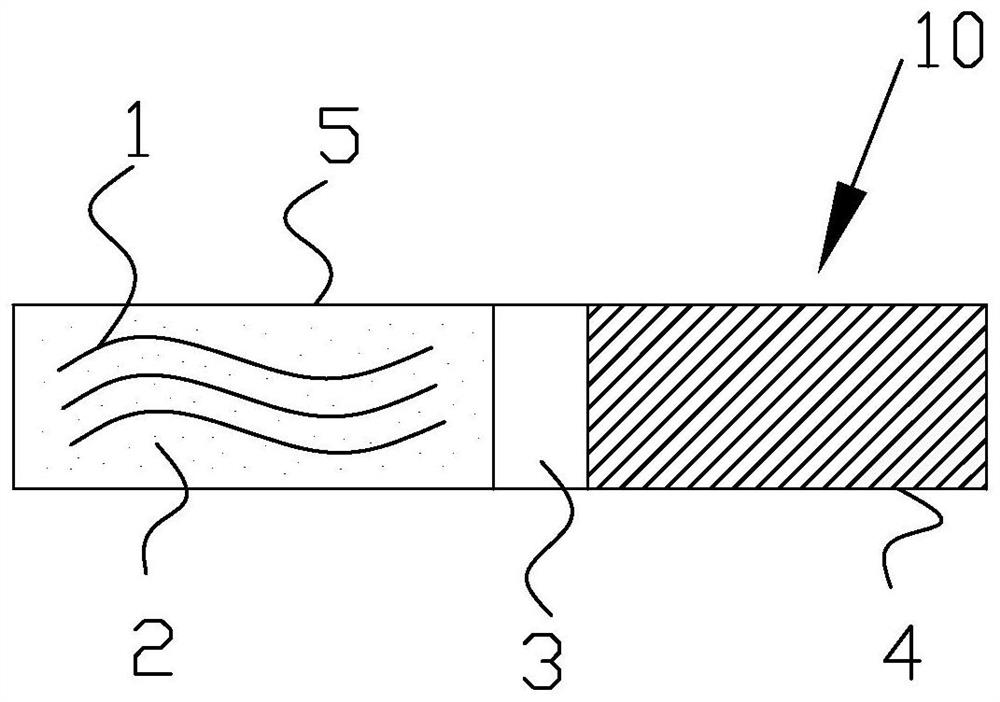

[0056] see figure 1 , An aerosol generator according to an embodiment of the present invention includes a susceptor 1 , a substrate 2 , a support 3 , a suction nozzle 4 and a package 5 . The technical solution of this embodiment may not be provided with an aerosol generating coating and a heat transfer member.

[0057] The susceptor 1 is used to receive heat, microwave or electromagnetic field to generate heat, and is widely distributed inside the base material 2 , and is in sufficient thermal contact with the base material 2 to achieve efficient heat transfer to heat the base material 2 .

[0058] The substrate 2 is used to form an aerosol under heating.

[0059] The support member 3 is configured as a hollow flow channel structure or a porous flow channel structure. The support member 3 is arranged between the base material and the suction nozzle, and is used for supporting and insulating the base material 2 and guiding the flow of water. Aerosol.

[0060] The suction noz...

Embodiment 2

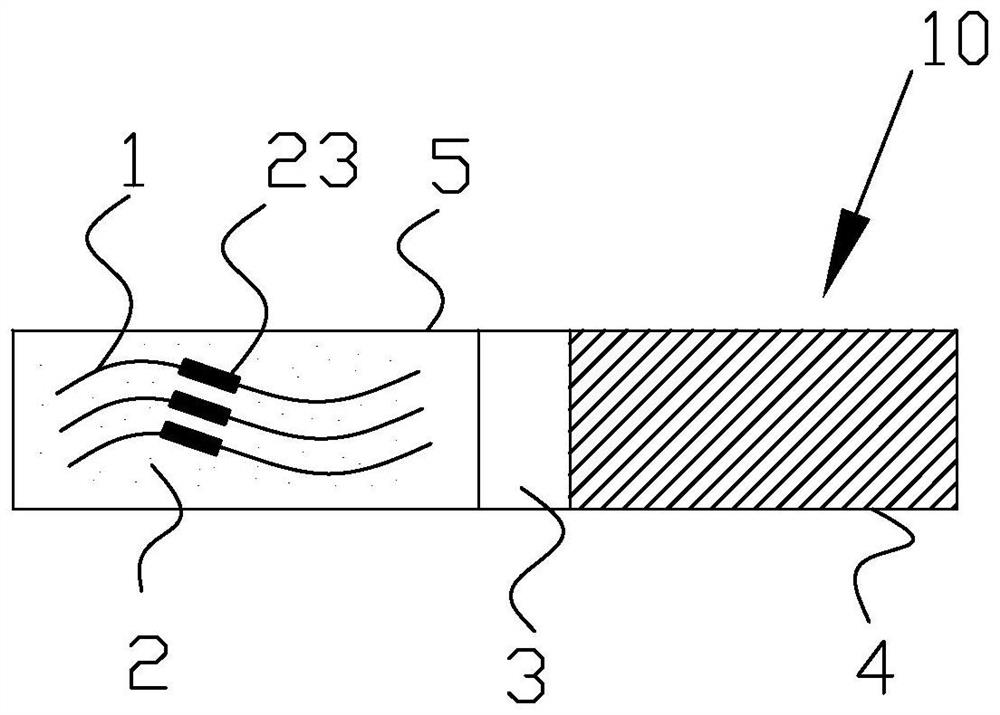

[0069] like image 3 , as a further description of this embodiment, an aerosol generator according to an embodiment of the present invention includes a susceptor 1 , a substrate 2 , a support member 3 , a suction nozzle member 4 and a package member 5 . The technical solution of this embodiment may not provide a heat transfer member. However, in this scheme, on the basis of Example 1, an aerosol generating coating III23 is added on the susceptor 1, and the aerosol generating coating III23 is covered on the susceptor 1 and is fully thermally contacted with the susceptor 1. Used to accelerate the generation of aerosols and increase the diversity of the aerosol components to adjust the composition or taste of the aerosols. Other features are the same as the first embodiment.

Embodiment 3

[0071] like Figure 4 , as a further description of this embodiment, an aerosol generator according to an embodiment of the present invention includes a susceptor 1 , a substrate 2 , a support member 3 , a suction nozzle member 4 and a package member 5 .

[0072] The susceptor 1 is set as a hollow structure for receiving heat, microwave or electromagnetic field to generate heat, distributed inside the base material 2 and fully thermally contacted with the base material 2 to achieve efficient heat transfer to heat the base material 2 .

[0073] The aerosol generator also includes an aerosol generating coating I21, the aerosol generating coating I21 is covered inside the susceptor, and is fully thermally contacted with the susceptor, so as to accelerate the generation of aerosol and increase the Diversity of aerosol composition to adjust the composition or taste of the aerosol. Other features are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com