Hydrogen-added sulfur hexafluoride thermocatalytic cyclic degradation device

A sulfur hexafluoride and thermal catalysis technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of no gas recovery device, insufficient gas catalyst reaction, environmental pollution, etc., and achieve easy filling. The effect of installing catalyst, ensuring test rigor and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

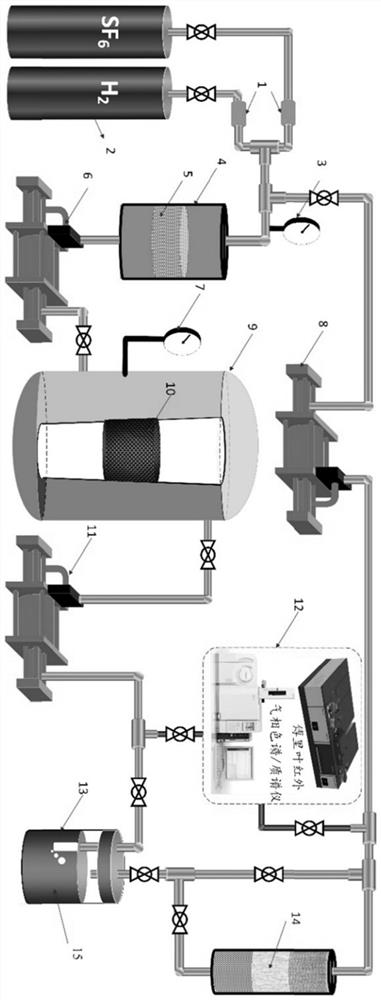

[0033] figure 1 The structure of the present invention is shown. The hydrogen-added sulfur hexafluoride thermal catalytic cycle degradation device includes a raw material gas tank 2, a pretreatment device 4, a primary pressure controller 6, a reactor 9, and a secondary pressure connected by pipelines in sequence. The controller 11 and the alkaline washing tank 13 also include a molecular sieve 14 and a tertiary pressure controller 8 connected to the exhaust port of the alkaline washing tank 13 in sequence; On the pipeline between the raw gas tank and the preprocessor 4; the pressure at the outlet of the three-stage pressure controller 8 is equal to the pressure at the outlet of the raw gas tank 2.

[0034] The raw material gas tank 2 consists of SF 6 Gas tank and H 2 The gas tanks are formed in parallel, and the outlet of the two gas tanks is provided with a quality controller 1 and then connected to the tee. A pretreatment agent 5 is arranged in the pretreatment device 4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Channel diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap