Method for on-line monitoring lens astigmatism

A kind of astigmatism and lens technology, applied in the field of lens astigmatism, can solve the problems of wasting production time and affecting the control accuracy of CD, so as to reduce the process cost, make up for the problems of low production capacity utilization and machine number differences, and improve the effect of real-time monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The implementation steps of the method of the present invention are:

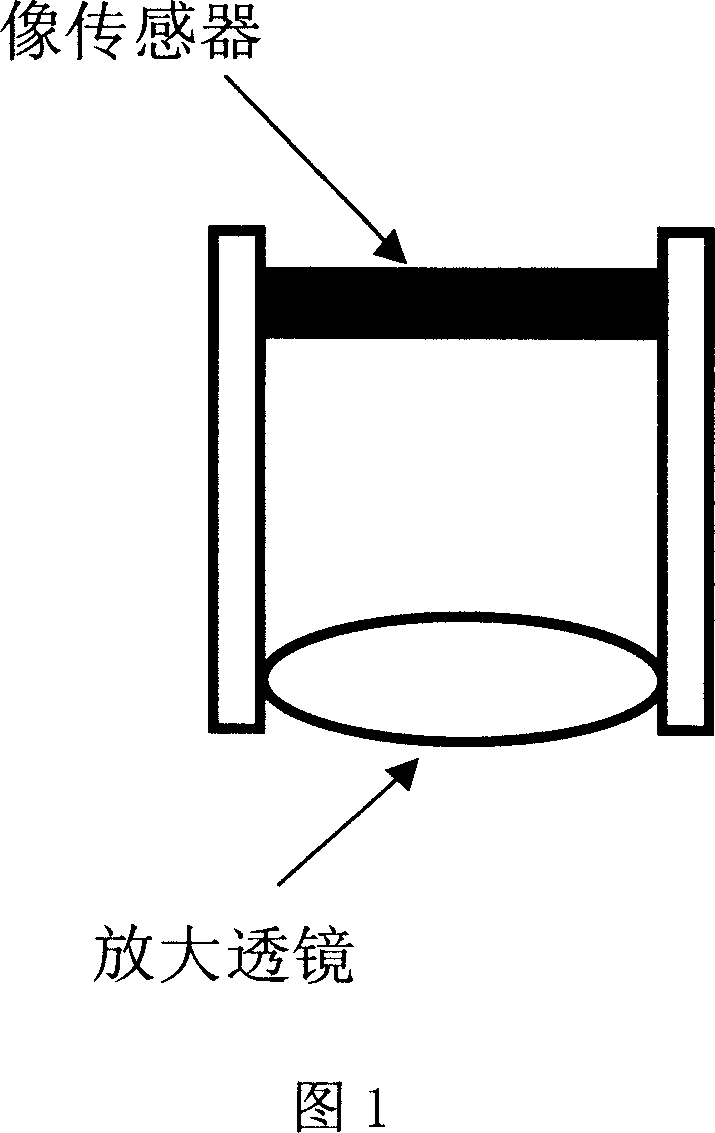

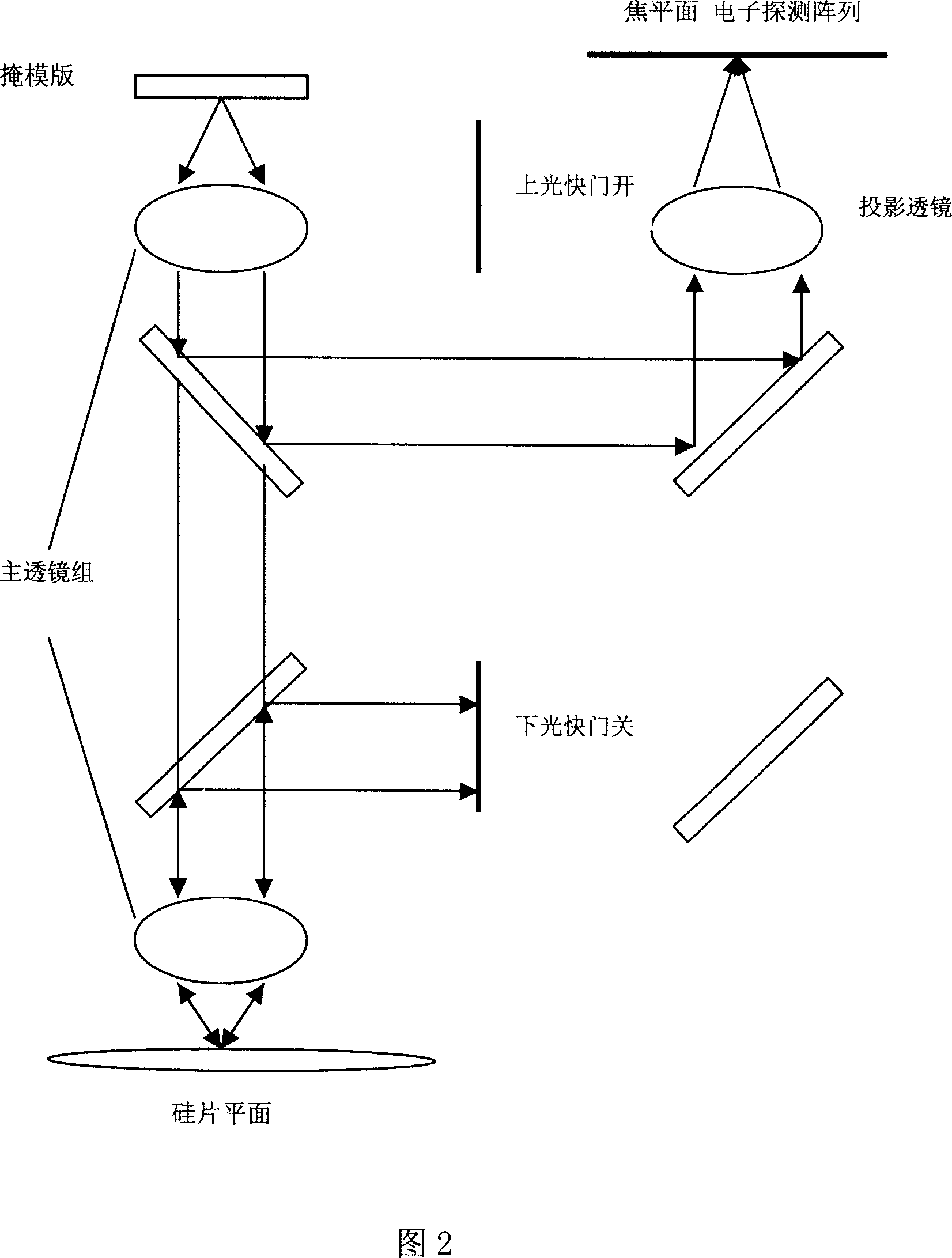

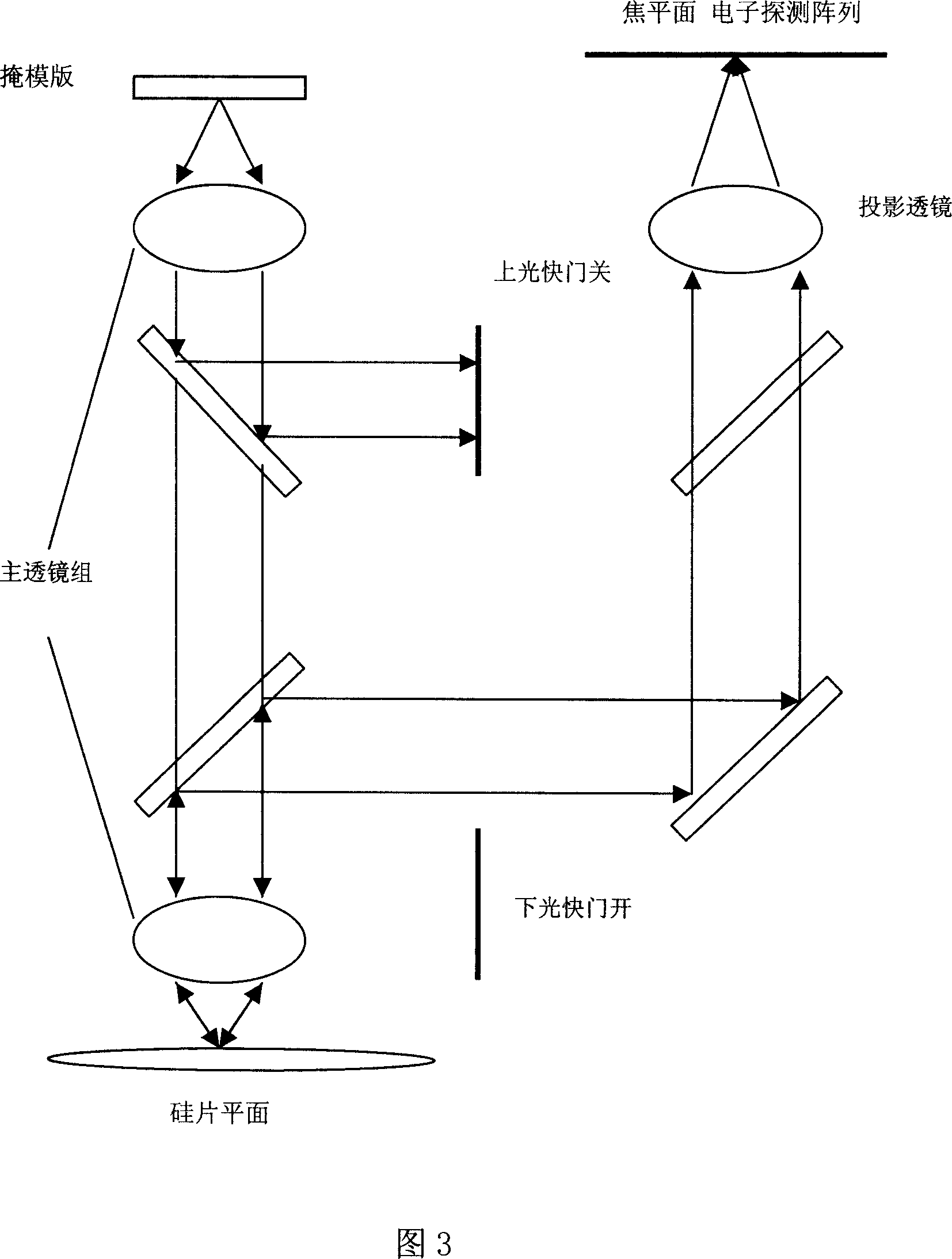

[0012] First, use the lithography machine itself to expose light waves, and record the aerial images of the test structure on the mask plane and the test structure converging on the silicon wafer plane in a focal plane through a lens system while working. on the detector array. The wavelength of the exposure light wave can be the exposure wavelength of all photolithography equipment in the industry, such as g-line (436nm), i-line (365nm), KrF (248nm), ArF (193nm) or F2 (157nm). The lens system at least includes: a main lens group, a 45-degree angle beam splitter group near the Fourier plane, a 45-degree angle mirror group, a projection lens, a focal plane aerial image collection detector array, and an electronically controlled optical shutter group; wherein, The 45-degree angle beam-splitter plate group near the Fourier plane includes at least two upper and lower 45-degree angle beam-splitter plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com