Environment-friendly and energy-saving solid waste treatment device and working method thereof

A processing device and energy-saving technology, applied in grain processing, manufacturing tools, presses, etc., can solve the problems of inconvenient solid waste compression processing, affecting waste reprocessing, increasing waste transportation volume, etc., to achieve convenient transportation. and secondary processing, saving operating energy and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

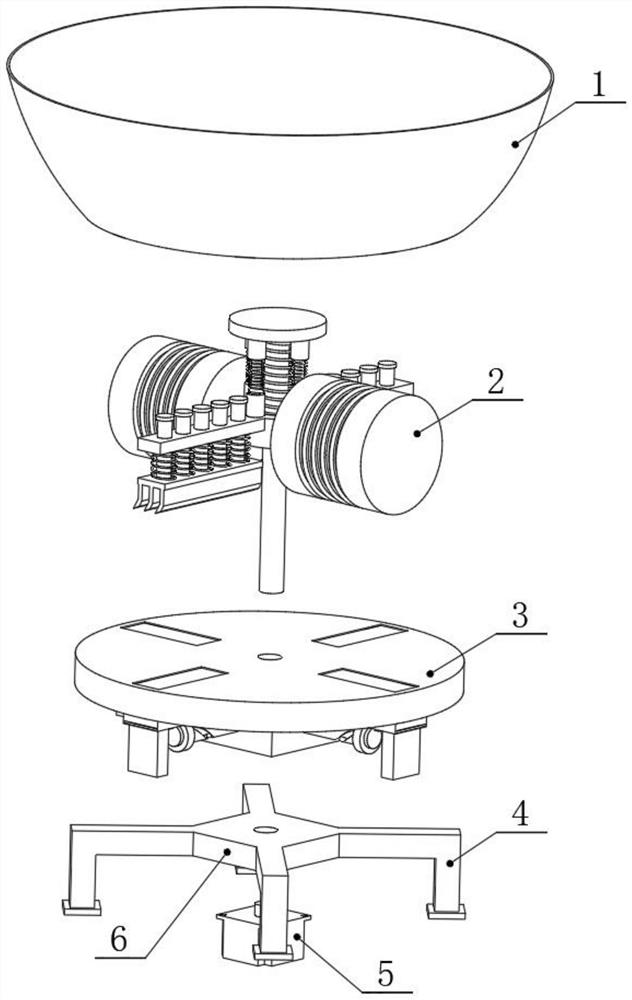

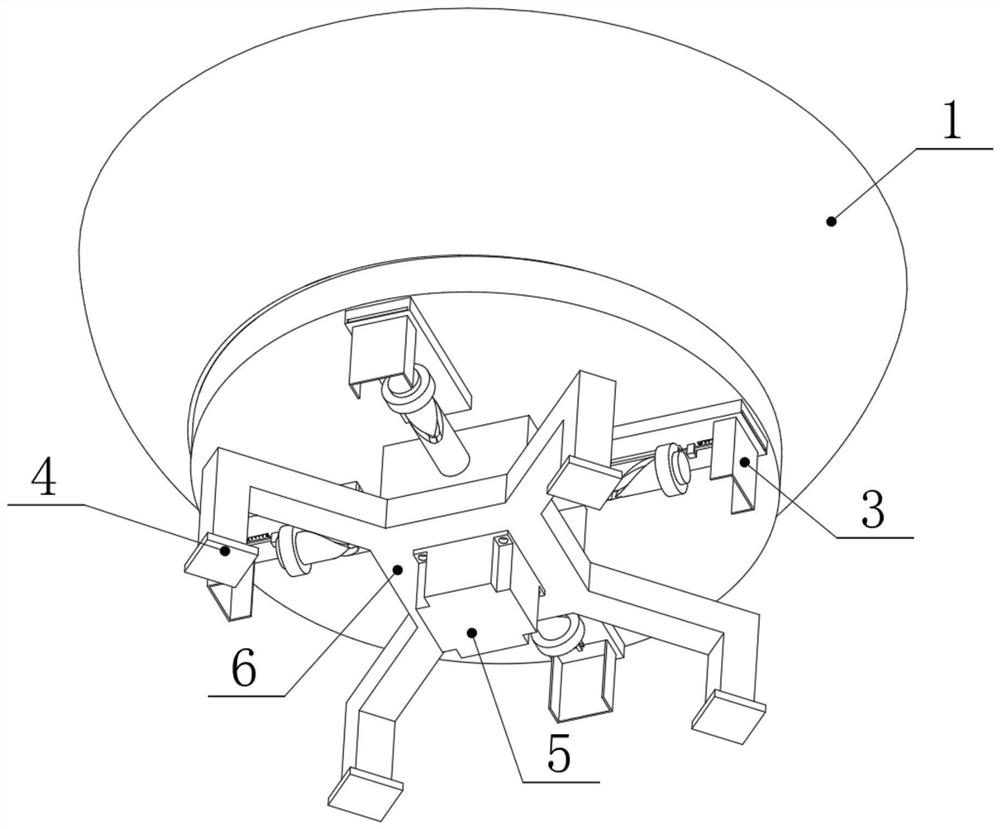

[0042] see Figure 1-15 , the present invention provides a technical solution: an environmental protection and energy-saving solid waste treatment device, comprising a support guide base 6 for supporting, and four sets of positioning legs 4 are fixedly installed on the outer end surface of the support guide base 6 evenly and equidistantly, and A geared motor 5 is fixedly connected to the center of the lower end face of the support guide base 6, a processing device 3 is fixedly installed on the upper end face of the support guide base 6, and a protective box 1 for protection is fixedly connected to the upper end face of the processing device 3. The inner end face of the support guide 6 and the processing device 3 is rotatably clamped with the processing device 2 .

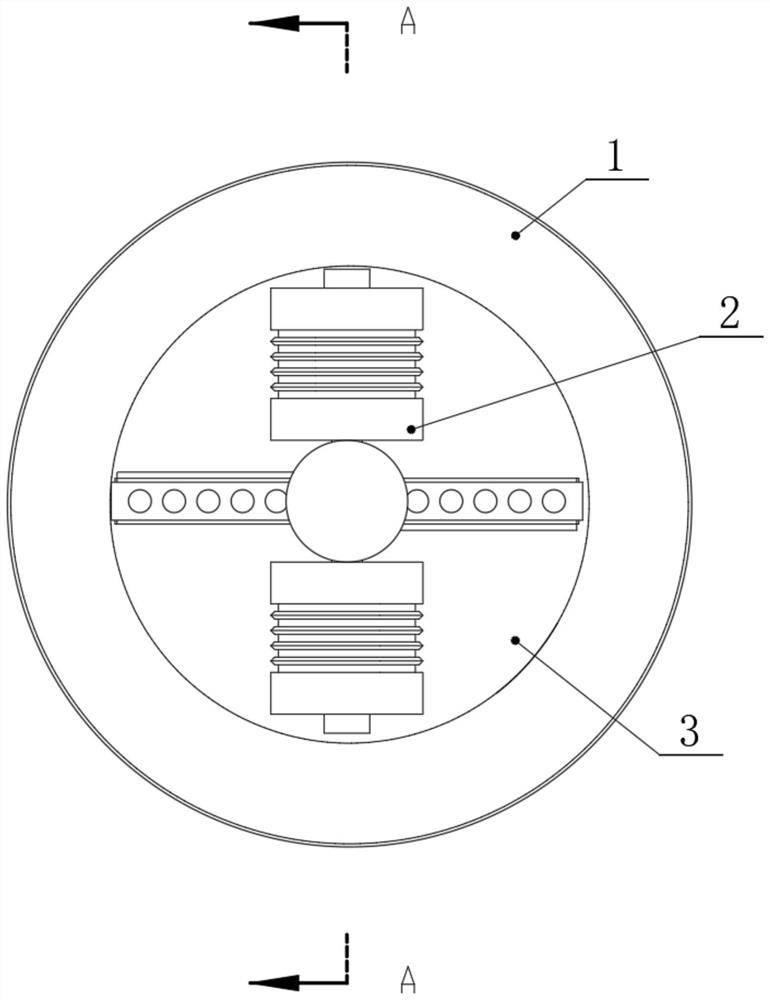

[0043] like Image 6 and Figure 7 , the processing device 2 includes a spring guide shaft 21, a connecting cover plate 22, a spring snap ring 23, a crushing roller 24, a cutting tool 25, a support card plate 26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com