Universal tool assembly line

A technology of assembly line and tooling, applied in the direction of injection device, etc., can solve the problems of long assembly line, inconvenient access, large occupation area, etc., and achieve the effect of shortening the length and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

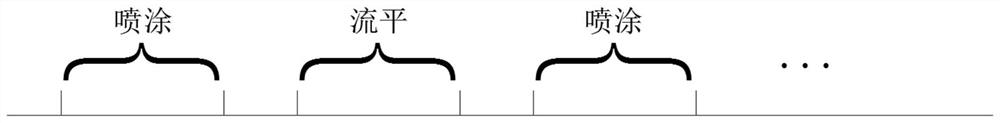

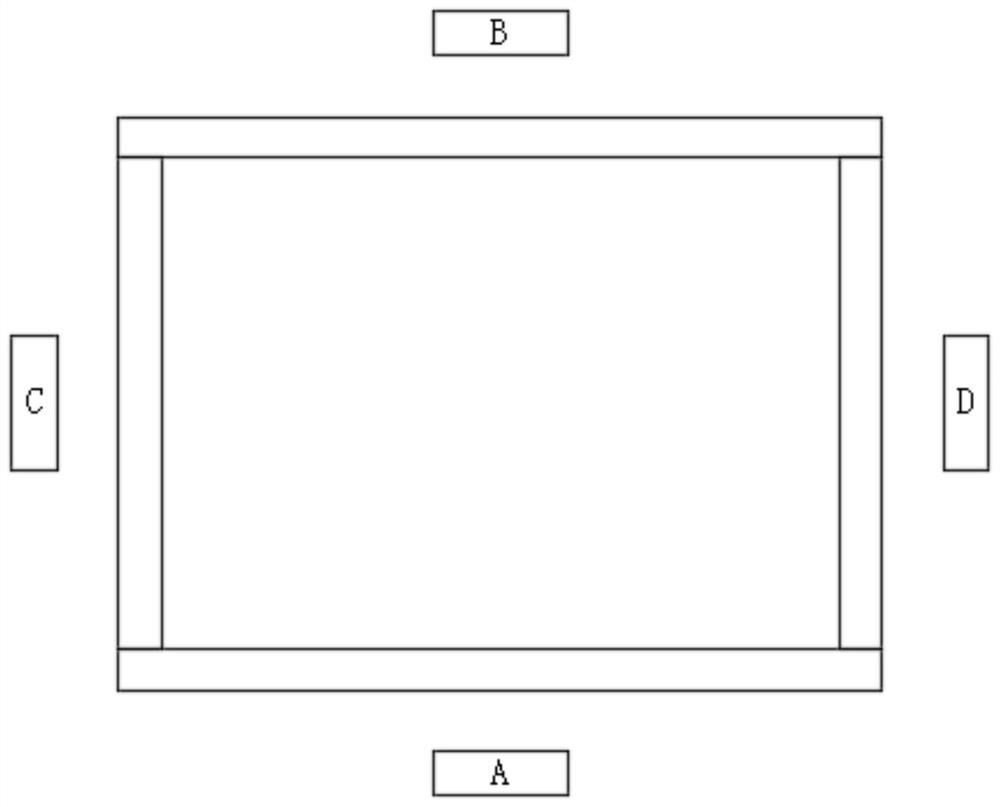

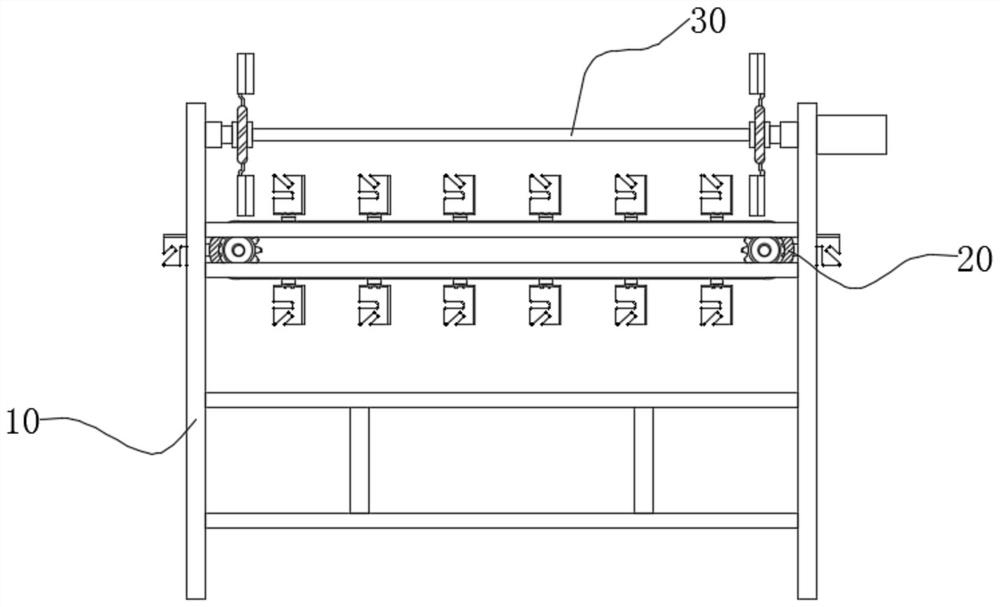

[0039] Universal tooling assembly line, including at least four station assembly lines, the four station assembly lines are arranged at 90 degrees respectively, and the four station assembly lines are:

[0040] Two lateral assembly lines 20 for painting, the two lateral assembly lines 20 are arranged in parallel, the lateral assembly line 20 includes a lateral rotating shaft 21, the lateral rotating shaft 21 is installed on the assembly line support 10 through a bearing seat one 22, and the outer side walls of the lateral rotating shaft 21 are fixedly connected There is a transverse sprocket 23, the outer side wall of the transverse chain wheel 23 is engaged with a transverse chain 24, the outer side wall of the assembly line support 10 is fixedly connected with a driving motor 1 25, and the output shaft of the driving motor 1 25 is fixedly connected with one end of the transverse rotating shaft 21. The set of universal tooling 40 is evenly installed on the outer side wall of t...

Embodiment 2

[0047] Universal tooling assembly line, including at least four station assembly lines, the four station assembly lines are arranged at 90 degrees respectively, and the four station assembly lines are:

[0048] Two lateral assembly lines 20 for painting, the two lateral assembly lines 20 are arranged in parallel, the lateral assembly line 20 includes a lateral rotating shaft 21, the lateral rotating shaft 21 is installed on the assembly line support 10 through a bearing seat one 22, and the outer side walls of the lateral rotating shaft 21 are fixedly connected There is a transverse sprocket 23, the outer side wall of the transverse chain wheel 23 is engaged with a transverse chain 24, the outer side wall of the assembly line support 10 is fixedly connected with a driving motor 1 25, and the output shaft of the driving motor 1 25 is fixedly connected with one end of the transverse rotating shaft 21. The set of universal tooling 40 is evenly installed on the outer side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com