Green and environment-friendly powder removing equipment

A green and environmentally friendly technology, applied in solid separation, separation methods, dispersed particle separation, etc., can solve the problems of reducing energy consumption, stone powder dissipation, energy consumption, etc., to reduce energy consumption, reduce resistance, and increase the flow area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

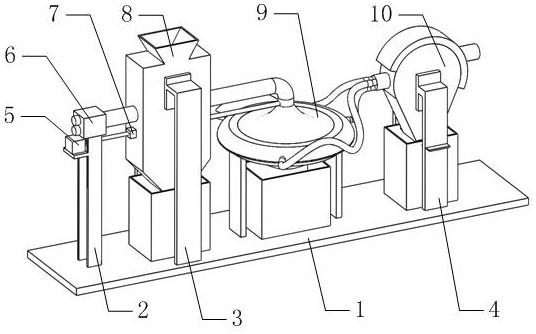

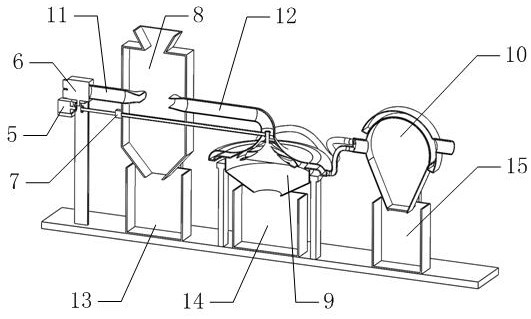

Image

Examples

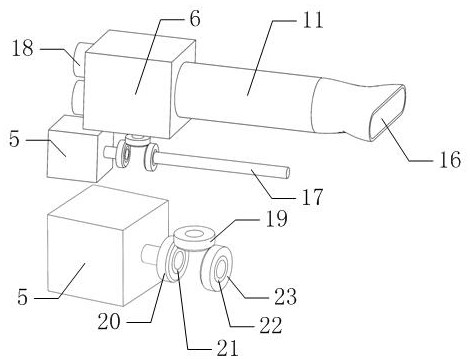

Embodiment approach

[0050] Embodiment: When using the equipment designed by the present invention, after adding the aggregate into the stone powder filter box 8 from the feeding hopper 26, the gas blown out by the air pump 6 will enter the stone powder filter box 8 after passing through the blowing pipe. The stone powder from the pipe plays a blowing action, so that the stone powder enters the suction pipe 12, and the machine-made sand is discharged from the discharge port 27 on the lower side of the stone powder filter box 8 into the machine-made sand collection box 13 for collection, and then enters the suction pipe. The stone powder in the pipe 12 enters the energy recovery shell 9 along the suction pipe 12, and the stone powder entering the energy recovery shell 9 will blow the turbine 32 to rotate, and the stone powder and gas enter the energy recovery shell 9 along the turbine 32. It will be discharged from the air outlet channel between the annular cone plate 34 in the energy recovery housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com