Optical fiber laser cutting machine with positioning mechanism

A fiber laser and positioning mechanism technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of inability to locate, affect production efficiency, and lack of convenient positioning mechanism, etc., achieve strong practicability and improve mobile stability , Good positioning and clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

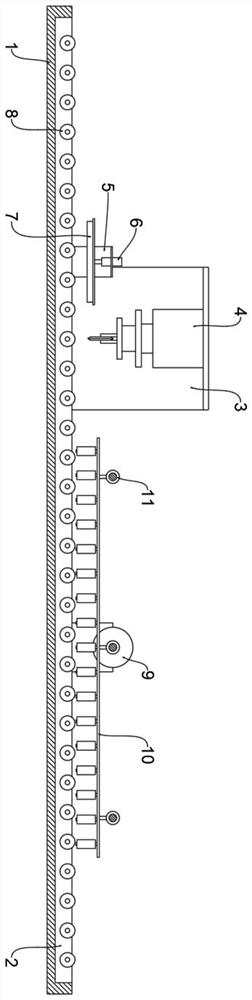

[0019] see figure 1 , a fiber laser cutting machine with a positioning mechanism, including a workbench 1, a groove body 2 is arranged on the workbench 1, a number of transport rollers 8 are evenly arranged in the groove body 2, and the workbench 1 is provided with A first mounting plate 3, a cutting device 4 is provided on the first mounting plate 3, a positioning assembly 10 is provided on the worktable 1 at a position on one side of the first mounting plate 3, and a side of the positioning assembly 10 is provided There is an adjusting assembly 9, the adjusting assembly 9 is used to drive the positioning assembly 10 to operate, and a fixing assembly is provided at the other side of the first mounting plate 3, and the positioning assembly 10 is used to clamp the side of the plate The fixing assembly is used for cooperating with the transport roller 8 to fix the position of the plate during cutting.

[0020] see figure 1 , 3 , the positioning assembly 10 includes a movable ...

Embodiment 2

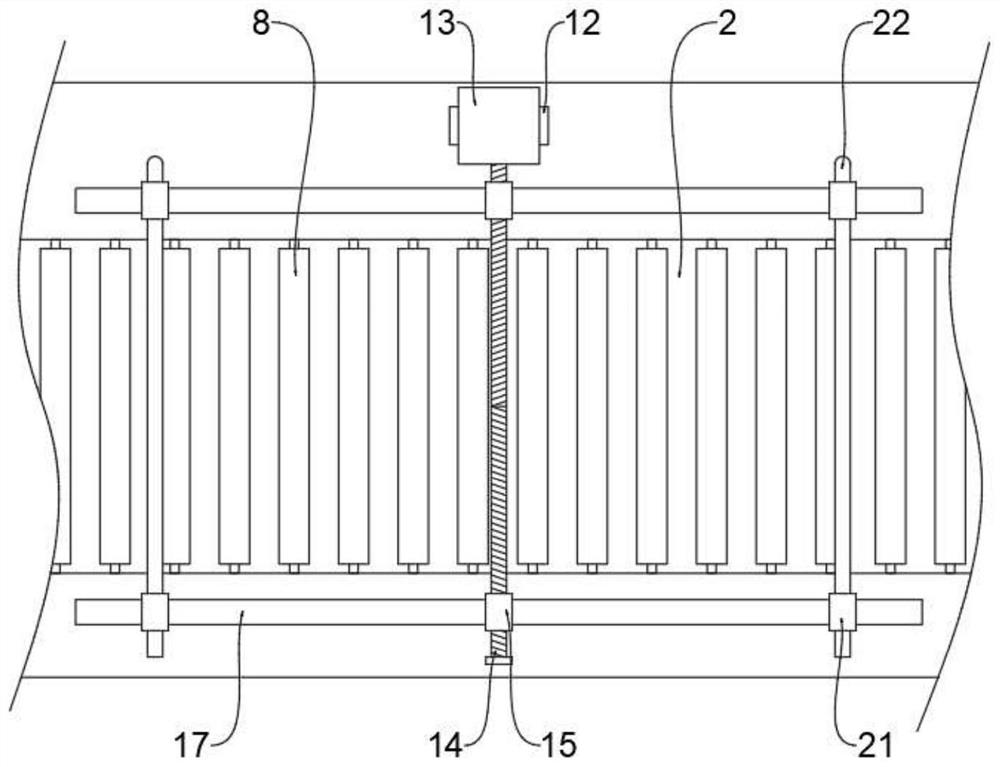

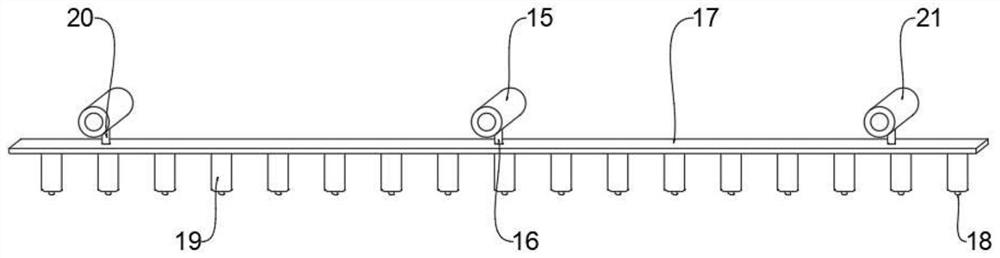

[0022] see figure 1 , 2 On the basis of the first embodiment, the adjustment assembly 9 includes a mounting seat 12 arranged on the workbench 1, a driving member 13 arranged on the mounting seat 12, and a threaded rod 14 connected to the extension of the driving member 13. And the two threaded sleeves 15 symmetrically arranged on the threaded rod 14, the damaged threaded rod 14 has two sets of external threads with symmetrical and opposite thread directions, and the outer walls of the two threaded sleeves 15 pass through the first connecting rod 16. They are respectively connected with the two movable plates 17. In this embodiment, rail assemblies 11 are provided on both sides of the adjustment assembly 9. The rail assemblies 11 include positioning rods 22 arranged on the The two positioning sleeves 21 on the positioning plate, and the outer walls of the two positioning sleeves 21 are respectively connected with the two movable plates 17 through the second connecting rod 20 ....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap