Glazed tile grinding and glaze removing device

A glazed tile, grinding technology, applied in the direction of grinding drive device, grinding/polishing safety device, grinding workpiece support, etc., can solve the problems of chamfering grinding, inability to facilitate glazed tiles, soaking, etc., to avoid displacement , Convenient drying treatment, avoid the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

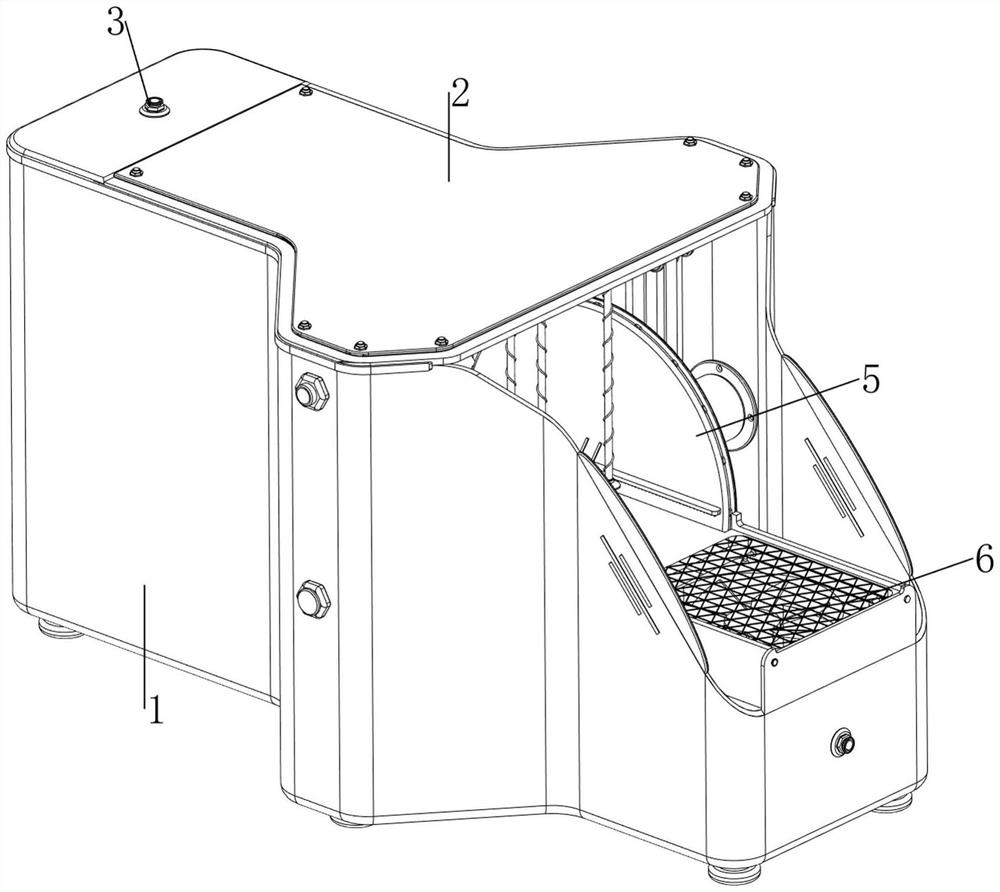

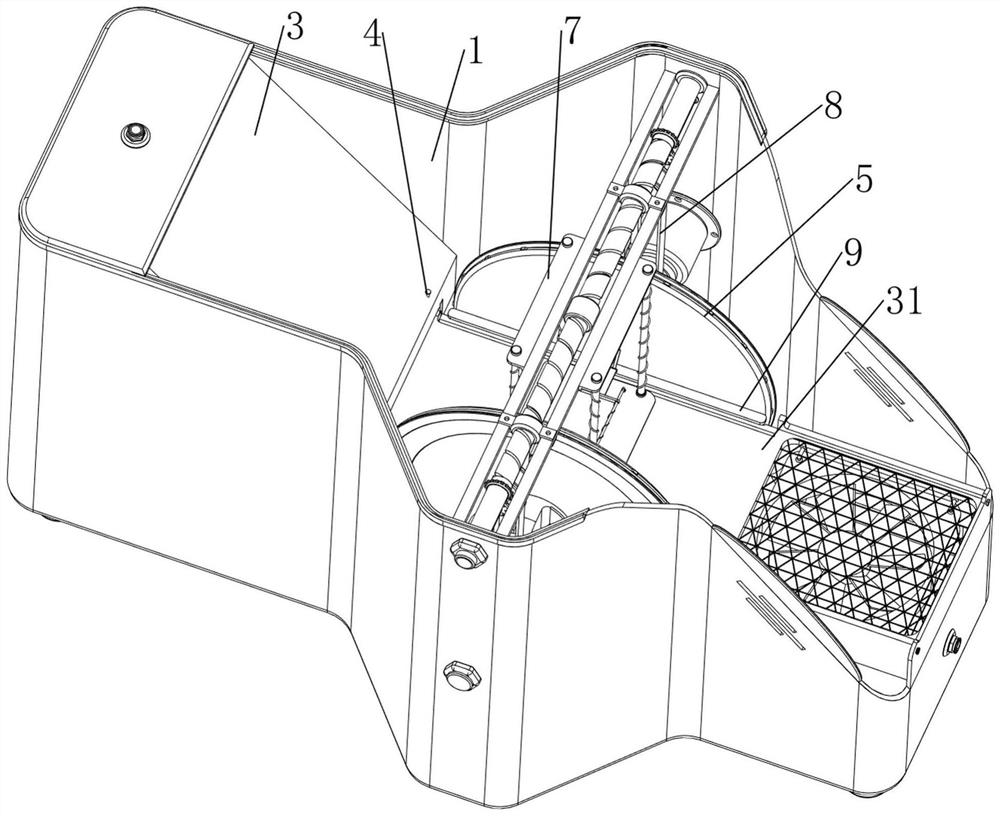

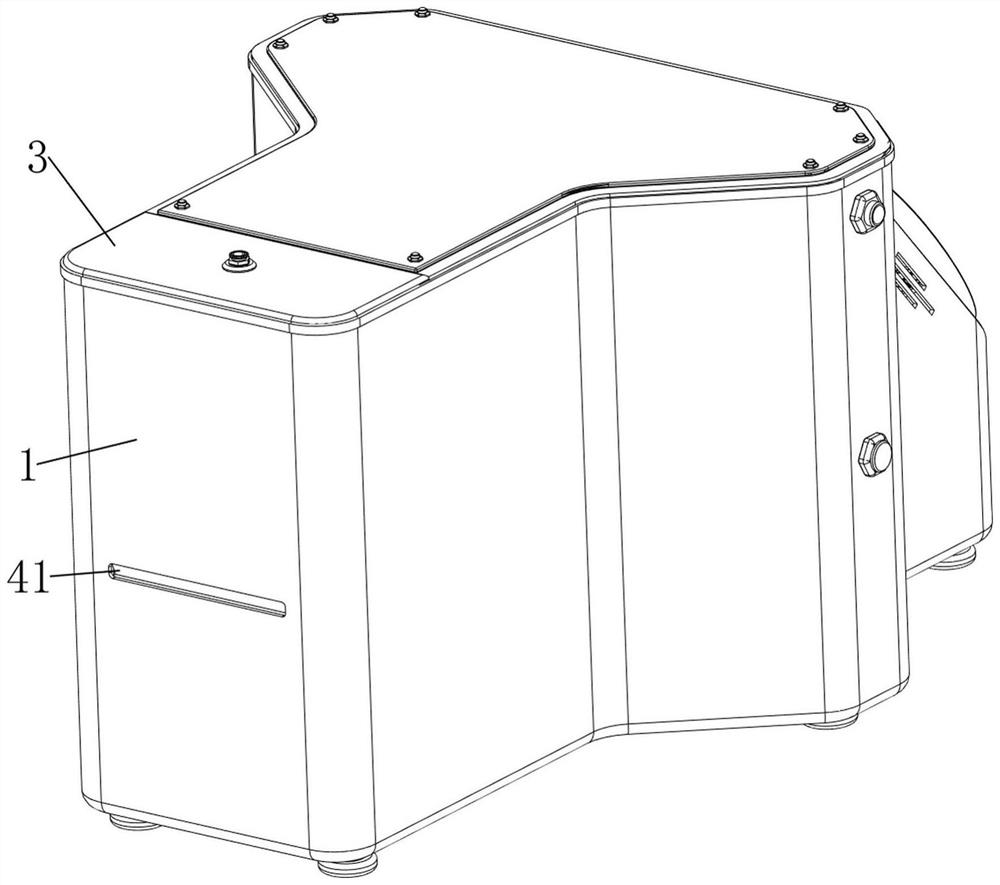

[0034] A glazed tile grinding and deglazing device, such as figure 1 and figure 2 As shown, it includes an outer frame 1, a frame plate 2, a water tank 3, a first slide rail 31, a blocking mechanism 4, a grinding mechanism 5 and a chamfering mechanism 8. The upper side of the middle of the outer frame 1 is connected with a frame plate 2, and the outer The upper left part of the frame 1 is bolted with a water tank 3. A first slide rail 31 for placing glazed tiles is welded between the water tank 3 and the outer frame 1. The water tank 3 is provided with a blocking mechanism 4 for blocking water. A grinding mechanism 5 for grinding the glazed tiles and a chamfering mechanism 8 for automatically chamfering the glazed tiles are provided.

[0035] like image 3 and Figure 4 As shown, the blocking mechanism 4 includes an inclined plate 41, a sliding sleeve 42 and a first spring 43, and two sliding sleeves 42 symmetrically arranged in the front and rear are bolted to the left in...

Embodiment 2

[0041] On the basis of Example 1, as figure 1 and Figure 7 As shown, it also includes a drying mechanism 6 for drying glazed tiles. The drying mechanism 6 includes a drying net 61, a fan 62 and a fixed rod 63. The right part of the outer frame 1 is bolted with two symmetrical A fan 62 for air circulation is installed between the four fixing rods 63 by means of screws, and a drying net 61 located above the fan 62 is bolted to the right part of the outer frame 1 .

[0042] After the glazed tiles are pushed out to the right from the first slide rail 31, the operator places the glazed tiles on the drying net 61, and then the operator starts the fan 62 to dry the glazed tiles through the fan 62, so as to make the glazed tiles dry. The tiles are dried to avoid water erosion on the glazed tiles. After the drying of the glazed tiles is completed, the operator turns off the fan 62 and takes out the dried glazed tiles from the drying net 61 .

Embodiment 3

[0044] On the basis of Example 2, as figure 2 , Figure 8 and Figure 11 As shown, it also includes a positioning mechanism 7 for fixing the glazed tiles. The positioning mechanism 7 includes a lower pressing frame 72, a second spring 73 and a second sliding rail 93. The lower pressing frame 72 of the glazed tile is fixed. The lower side of the lower pressing frame 72 is an arc-shaped surface that protrudes downward in the middle. Two second springs 73 are connected between the lower pressing frame 72 and the fixing plate 71. The upper side of 72 is welded with two second sliding rails 93 which are arranged symmetrically on the left and right sides.

[0045] When the glazed tile moves to the right after soaking, the glazed tile will press the lower pressing frame 72 to move upward during the process of moving to the right, the second spring 73 will be compressed, and then the lower pressing frame 72 will stabilize the glazed tile in the first sliding position. In order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com