Anchoring adhesive and preparation process thereof

A kind of reinforced glue and basic technology, applied in the field of planted reinforced glue and its preparation technology, can solve the problems of reduced fatigue resistance, low thermodynamic entropy, shortened service life, etc., to reduce crystallinity, increase thermodynamic entropy, and enhance chaos. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

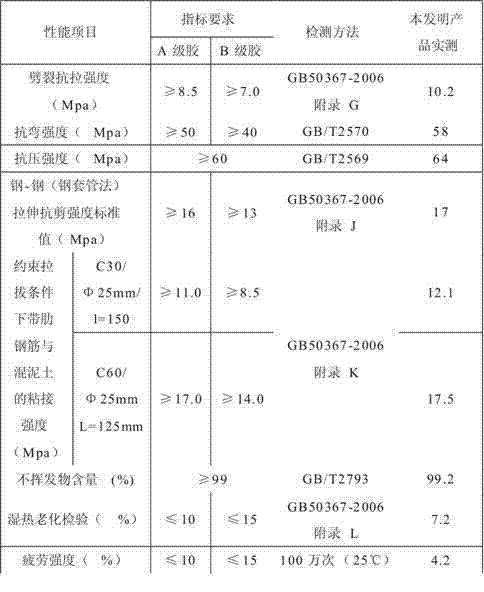

Image

Examples

Embodiment Construction

[0022] Below we will further illustrate the present invention in conjunction with specific embodiments.

[0023] Take by weighing 60kg of epoxy resin, 35kg of silicon micropowder, fumed silica, calcium carbonate and talcum powder, the anti-sagging agent is fumed silica 1kg, and the anti-settling agent is selected modified polyamide wax powder (provided by Taiyuan Meitexiang Technology Co., Ltd.) 2kg and the wetting agent selected from organic silicon wetting agent FY-4808 wetting extender (produced by Guangzhou Fluorine Silicon Technology Co., Ltd.) 2kg; put them into the kneader and mix in turn, and the temperature during the mixing process is 60 °C, the time is 40min, and A component is obtained.

[0024] Take by weighing diethylenetriamine, triethylenetetramine, tetraethylenepentamine and polyethylene polyamine total 90kg, modifying agent selects 9.9kg of hydroxyl-terminated polybutadiene, catalyst (zinc stearate, cobalt naphthenate and cyclic Zinc alkanoate) 0.1kg in a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com