Defect positioning system and method for sheet slitting

A defect and sheet technology, which is applied in the field of defect positioning system for sheet cutting, can solve the problems of inaccurate positioning of defects, unfavorable manufacturing costs, complex system structure, etc., and achieve the elimination of defective materials, reduction of missed detection rate, and stability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to better understand the above technical solutions, the above technical solutions will be described in detail below with reference to the accompanying drawings and specific embodiments.

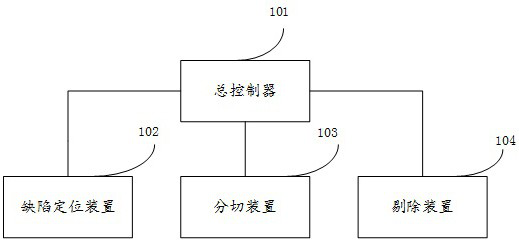

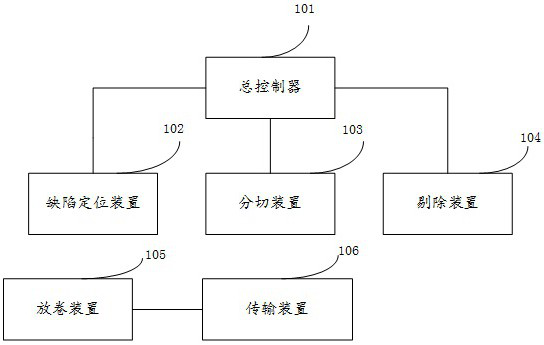

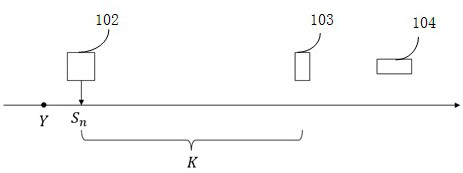

[0059] refer to figure 1 , in some embodiments, a defect locating system for sheet material slitting is provided, comprising a general controller 101, a defect locating device 102, a slitting device 103 and a rejecting device 104 arranged in sequence along the sheet moving direction;

[0060] The defect locating device 102 is used to detect sheet defects by machine vision and record the length position of the defect, and the slitting device 103 is used to cut the sheet according to the slitting control signal and record each actual cutting length position;

[0061] The controller is configured to calculate the average length of the slice according to the actual cutting length position, and when the defect location device 102 detects a sheet defect, judge the sheet defect accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com