Movable feeding device of novel-structure rubber machine

A feeding device and a new structure technology, applied in the direction of solid separation, chemical instruments and methods, grids, etc., can solve the problems of affecting normal use, impurity retention, impurity is not easy to discharge, etc., to achieve the effect of avoiding rubber falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

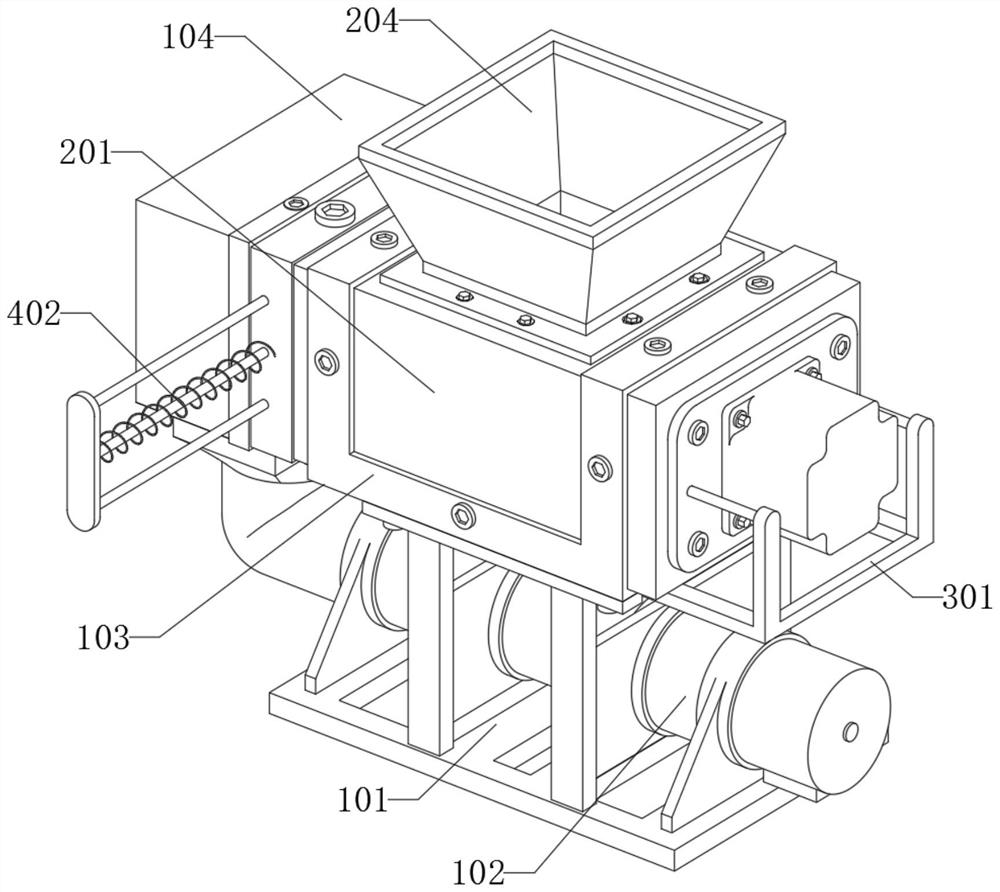

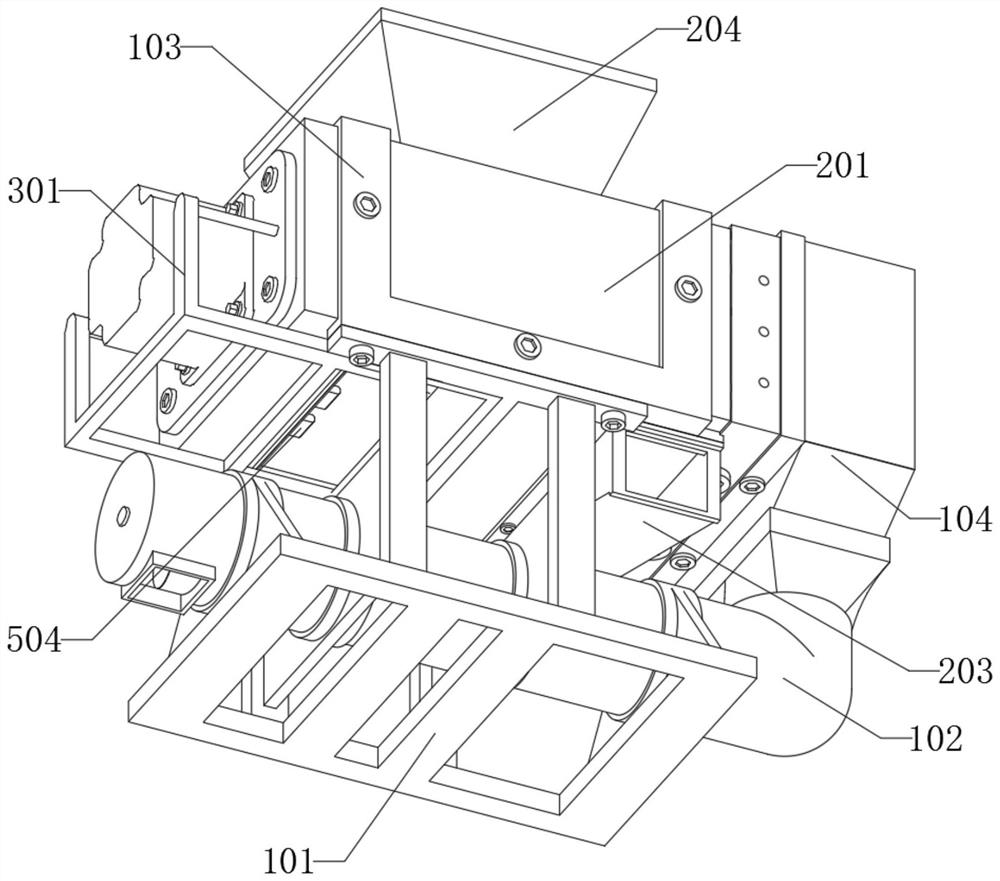

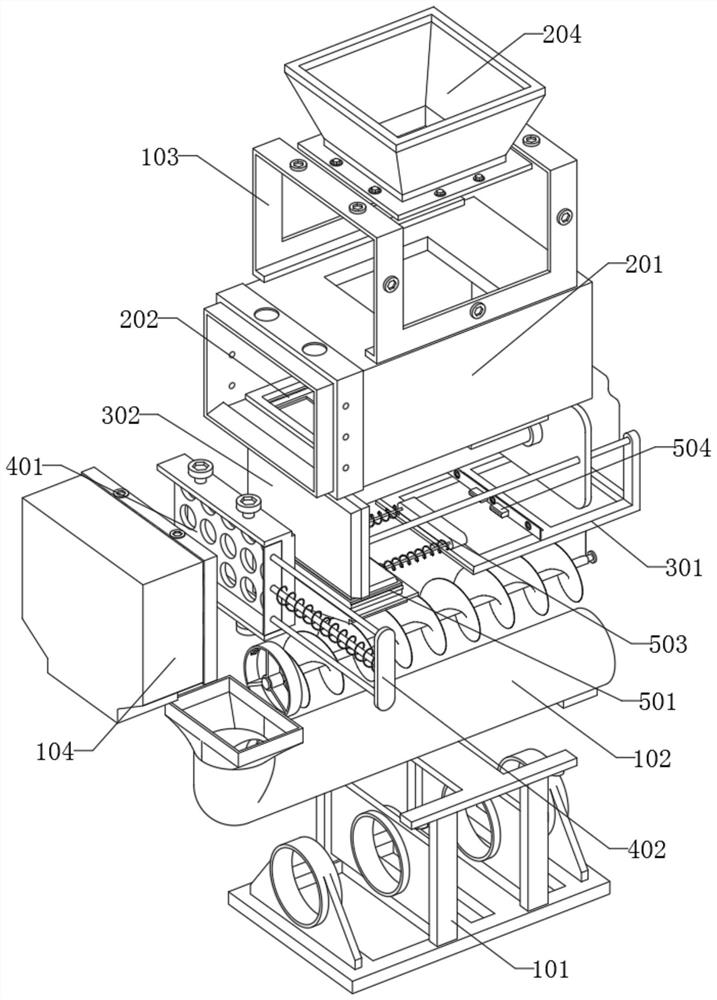

[0040] Example: please refer to Figure 1 to Figure 14 : The present invention proposes a new structure rubber mechanical movable feeding device, which includes: a mixing part 1; There is an inverted U-shaped protrusion, a support frame is provided inside the bottom frame 101, and a circular through hole is provided on the support frame of the bottom frame 101; the bottom frame 101 is used to install and fix other structures of the device, so as to facilitate the overall stability of the device, Make it easy to use; push part 2, the push part 2 is arranged on the top of the mixing part 1, the pushing cylinder 201 of the pushing part 2 is fixed in the fixing frame 103 of the mixing part 1 by screws, and the right side of the pushing cylinder 201 passes through The drainage cylinder 104 of the mixing part 1 is fixed with screws, and the pushing part 2 includes: a card slot 202, the card slot 202 is a rectangular groove, the top of the card slot 202 is connected with a trapezoida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com