Electric bicycle frame

A technology for electric bicycles and frames, applied to bicycle frames, bicycle accessories, bicycle auxiliary equipment, etc., can solve problems such as poor connection strength, cut off of brake lines or cables, and head tube damage, etc., and meet the requirements for increasing strength and ensuring strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

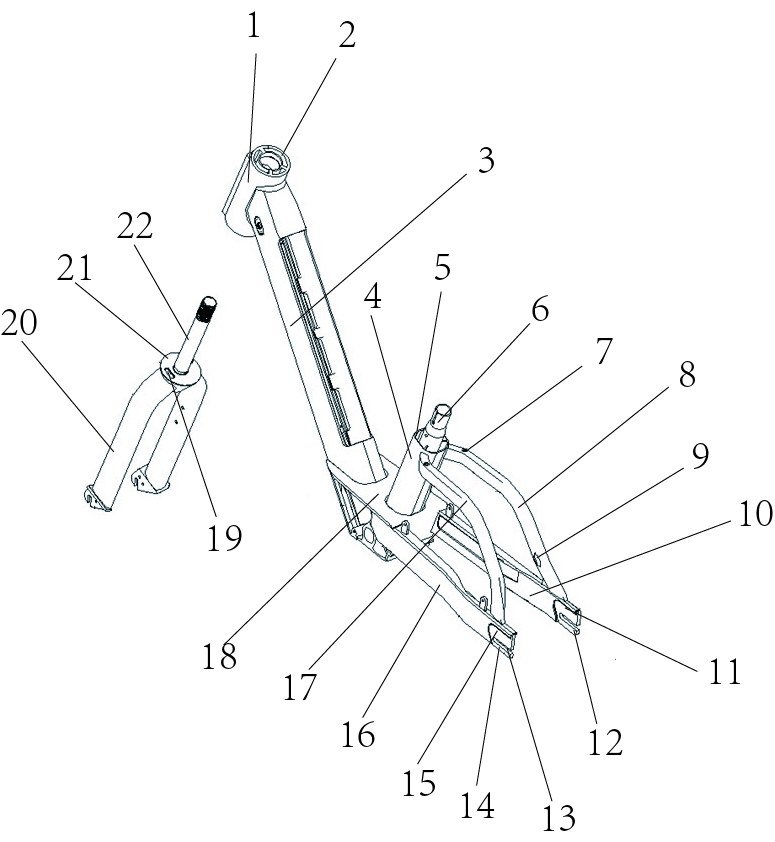

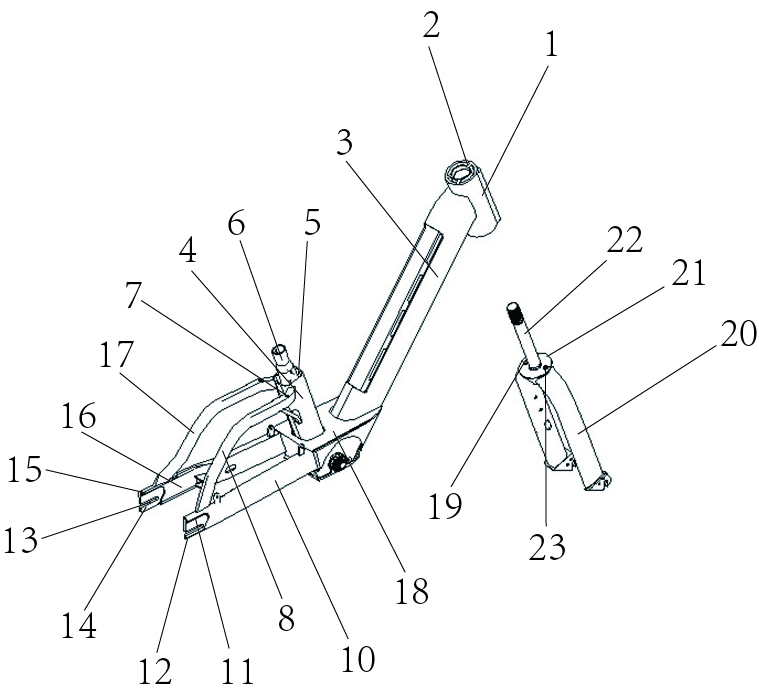

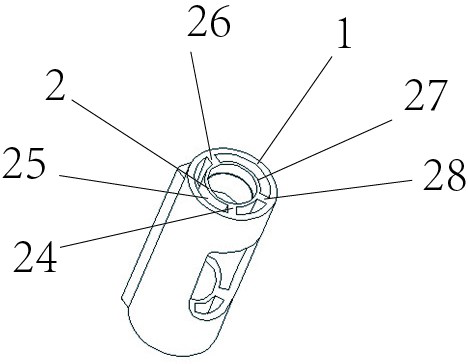

[0024] refer to Figure 1-5 As shown, an electric bicycle frame includes a frame and a front fork, the frame includes a head tube and an inclined tube 3, the head tube includes a first inner tube 2 and a first outer tube 1 with a spacing, the first A number of reinforcing ribs are arranged between an inner tube 2 and the first outer tube 1, and a first wire hole 25 and a limit hole 27 are formed; the front fork includes a riser tube 22, a fork shoulder 21 and a fork foot 20, so One side of the fork shoulder 21 is provided with an annular waist hole 19, and the other side is provided with a raised positioning member 23. The annular waist hole 19 coincides with the first wire hole 25, and the positioning member 23 is placed on the inside the limiting hole 27 .

[0025] Among them, there are three reinforcing ribs in total, including a first reinforcing rib 26, a second reinforcing rib 24, and a third reinforcing rib 28, and the first reinforcing rib 26 is arranged at -5° to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com