Lamp strip caching process and caching equipment

A caching device and caching technology, which is applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problem of out-of-sync production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

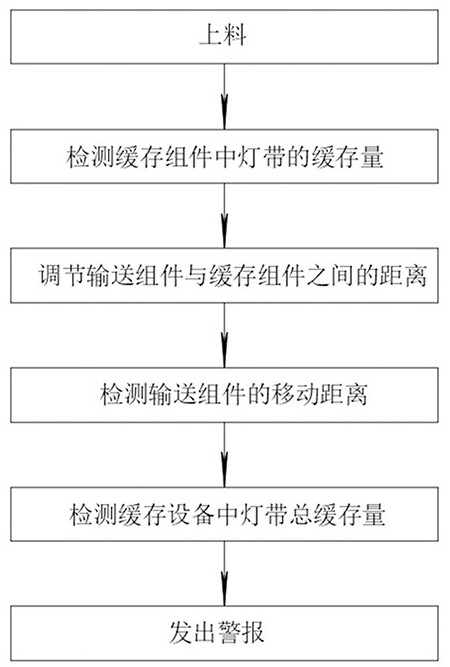

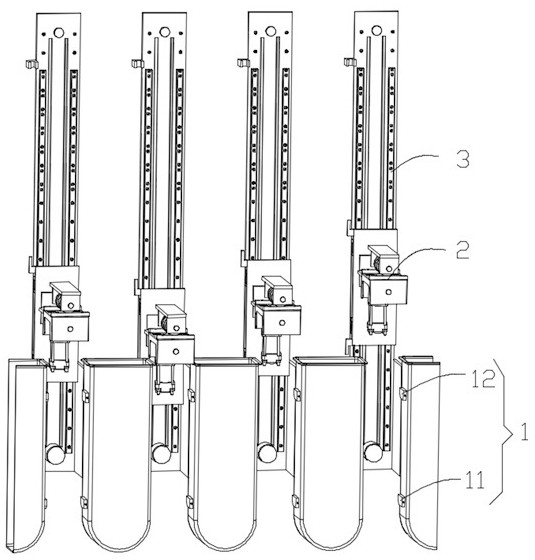

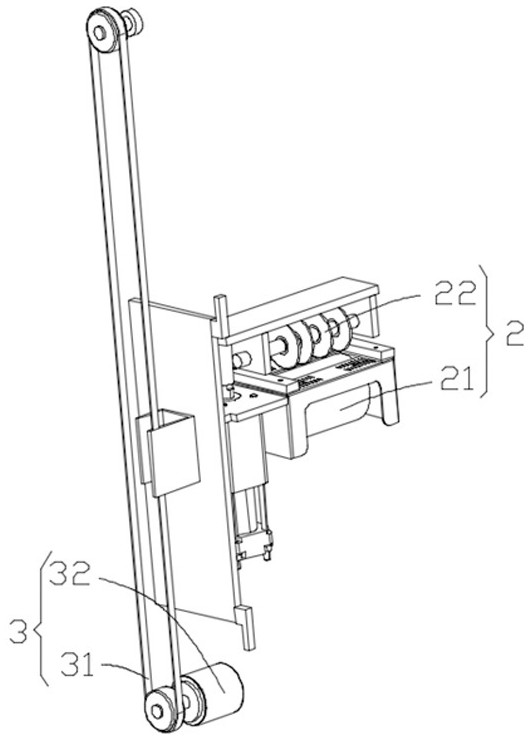

[0031] In a typical embodiment of the present application, such as Figure 1-3 As shown in the figure, a light strip buffering process includes the following steps: feeding; detecting the buffering amount of the light strips in the buffering assembly 1; adjusting the distance between the conveying assembly 2 and the buffering assembly 1; detecting the moving distance of the conveying assembly 2; detecting The total buffered amount of light strips in the buffer device; an alarm is issued.

[0032] It can be understood that, after the light strips are loaded, the light strips are transported through the conveying assembly 2, and the buffering amount of the light strips in the buffering assembly 1 is detected. If the buffer capacity of the light strip in the buffer assembly 1 is full, increase the distance between the conveying assembly 2 and the buffer assembly 1 to increase the buffer capacity of the light strip; the moving distance of the conveying assembly 2 Carry out detect...

Embodiment 2

[0049] In another typical embodiment of the present application, such as Figure 1-3 As shown in the figure, a light strip buffering process includes the following steps: feeding; detecting the buffering amount of the light strips in the buffering assembly 1; adjusting the distance between the conveying assembly 2 and the buffering assembly 1; detecting the moving distance of the conveying assembly 2; detecting The total buffered amount of light strips in the buffer device; an alarm is issued.

[0050] It can be understood that, after the light strips are loaded, the light strips are transported through the conveying assembly 2, and the buffering amount of the light strips in the buffering assembly 1 is detected. If the buffer capacity of the light strip in the buffer assembly 1 is full, increase the distance between the conveying assembly 2 and the buffer assembly 1 to increase the buffer capacity of the light strip; the moving distance of the conveying assembly 2 Carry out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com