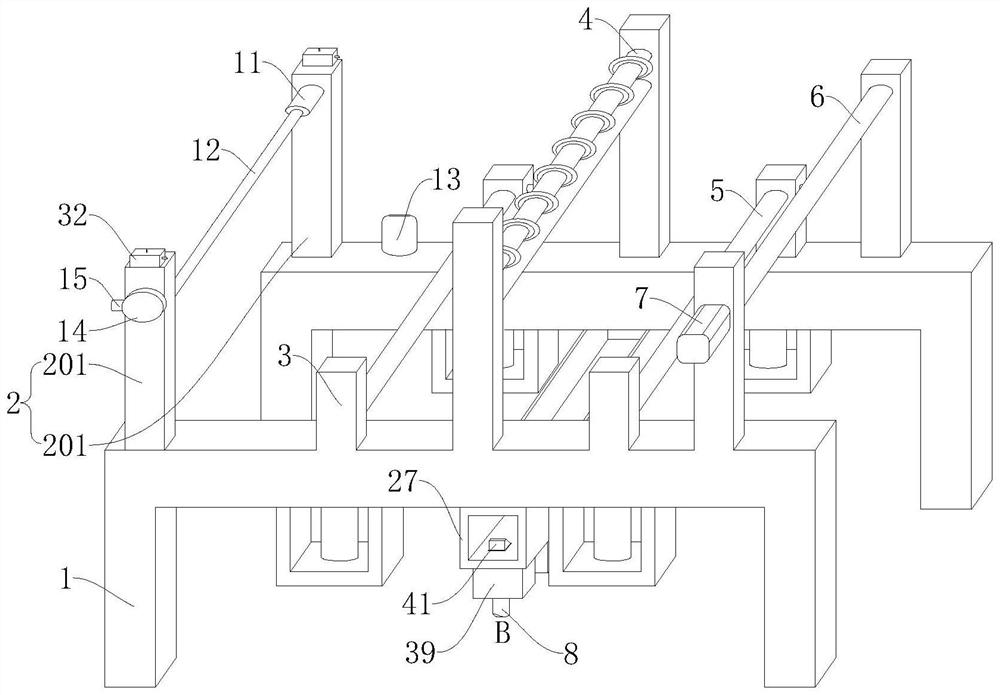

Mica paper slitting equipment

A technology of mica paper and equipment, which is applied in the field of mica paper cutting equipment, and can solve the problems of deterioration of lubricating oil on unloading racks and support rods, affecting cutting efficiency, and reducing winding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

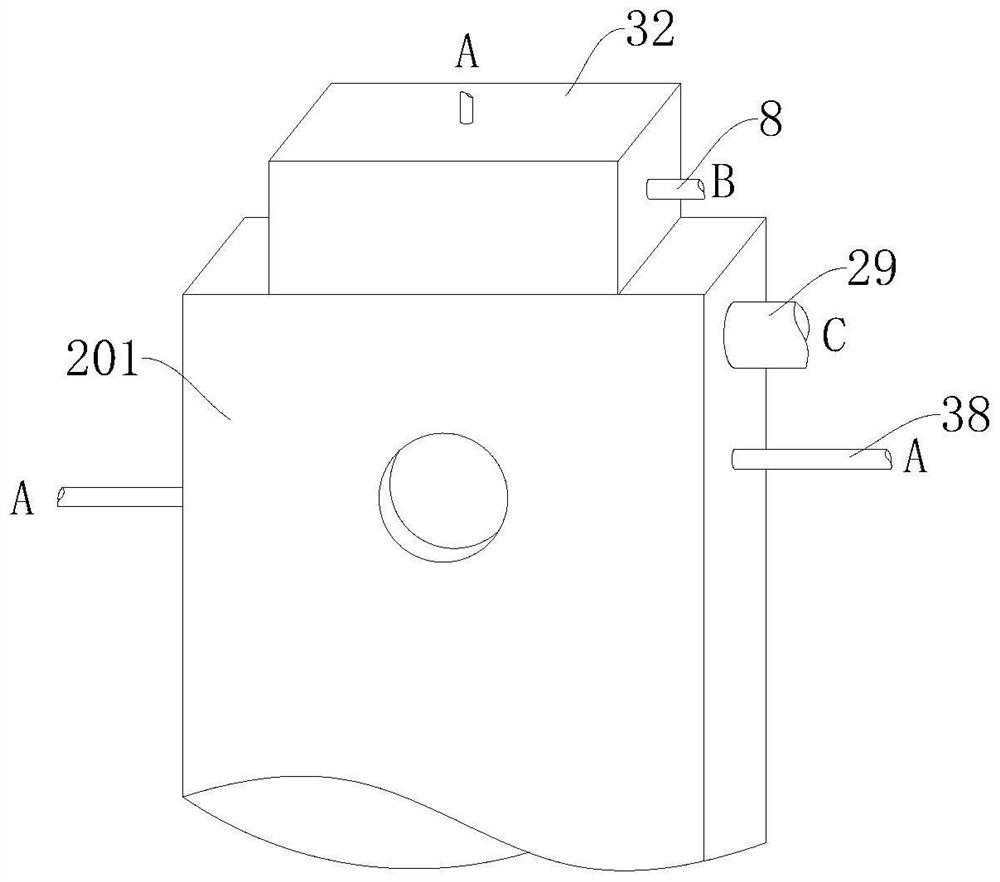

Method used

Image

Examples

Embodiment approach

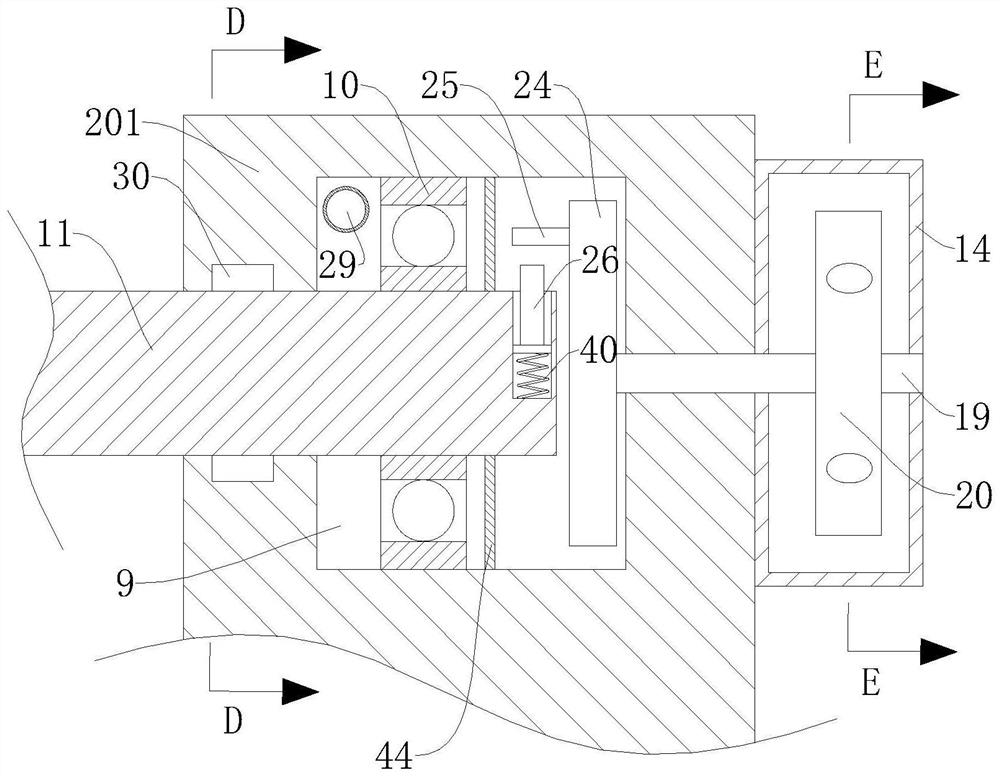

[0082] As an embodiment of the present invention, refer to image 3 , the trigger mechanism includes a rotating rod 19 installed in the installation box 14 for horizontal rotation, a first disc 20 is fixedly installed on the rotating rod 19, and a plurality of second cavities 21 are evenly opened on the first disc 20. A piston block 22 is movably arranged in the two cavities 21 , a first spring 23 is fixedly installed between the piston block 22 and the second cavity 21 , and a driving rotating rod 19 is arranged in the first cavity 9 to follow the installation rod 11 The linkage mechanism that rotates together.

[0083] In the initial state, the lubricating oil is in good condition. At this time, the bearing 10 can rotate rapidly. Therefore, under the action of the linkage mechanism, the rotating rod 19 rotates rapidly along with the mounting rod 11. Therefore, under the action of centrifugal force, the piston block 22 moves from the second Extends out of the cavity 21, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com