Bobbin paper manufacturing process and production equipment thereof

A technology of manufacturing process and production equipment, applied in the field of bobbin paper manufacturing technology and its production equipment, can solve the problems affecting the processing effect of raw materials, the outer wall of bobbin paper is broken, etc., so as to improve the production qualification rate, prolong the service life, improve The effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

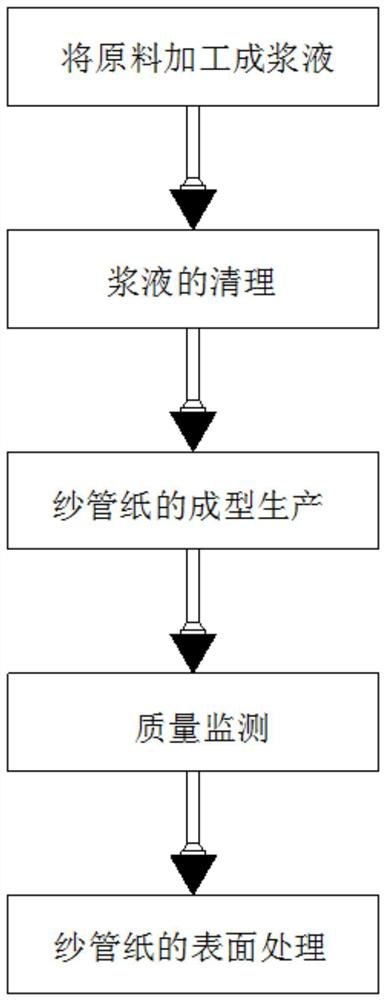

[0048] First, as figure 1 As shown, the present invention provides a bobbin paper manufacturing process, and the bobbin paper manufacturing process comprises the following steps:

[0049] Step 1, the raw material is processed into slurry, specifically:

[0050] Step X1: Collect waste paper or plant straws and other raw materials together, first use a screening device to screen them, screen out fine granular impurities such as sand inside the raw materials, and manually remove the raw materials during the screening process. Irrelevant foreign matter, that is, the pretreatment of the raw materials is completed, and then the raw materials are put into the inside of the shredder, and the raw materials are smashed;

[0051] Step X2, putting the crushed raw material into the refiner, and while the refiner is working, add tap water to the interior of the raw material, and the ratio of adding water is set to 1:0.55, that is, the bobbin paper slurry is obtained;

[0052] Step 2, clea...

Embodiment 2

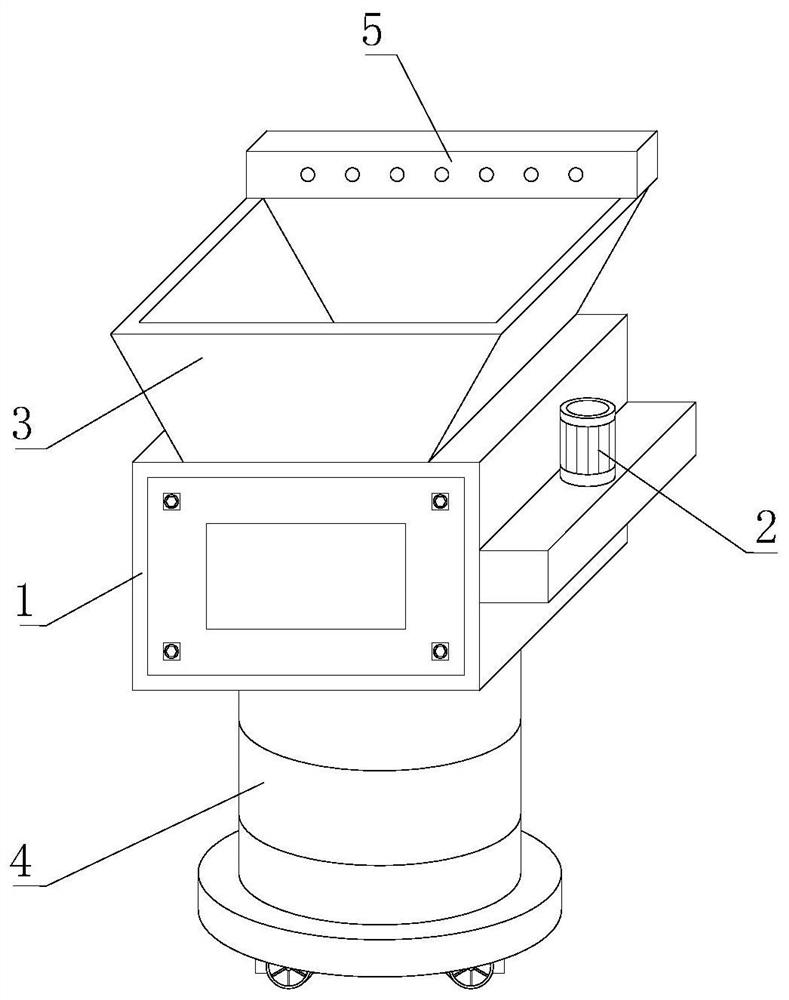

[0066] Second, as Figure 2-6 As shown, the present invention also provides a bobbin paper production equipment, comprising a shredder body 1, a drive motor 2 is arranged on the right side of the shredder body 1, and a material receiving frame 3 is fixedly connected to the top of the shredder body 1 , the bottom of the shredder body 1 is provided with a screening and recovery mechanism 4, and the top of the material receiving frame 3 is provided with a dust suction mechanism 5, which includes a hollow plate 51, an absorption cylinder 53 and a passing ring 539. A connecting rod 5391 is fixedly welded on the inner wall, a special-shaped block 5392 is fixedly welded on the middle of the connecting rod 5391, and an extension block 5393 is fixed and welded on the outer surface of the special-shaped block 5392, and the top and bottom of the extension block 5393 and the special-shaped block 5392 are fixed. A crushing thorn 5394 is attached.

[0067] The drive motor 2 is used to driv...

Embodiment 3

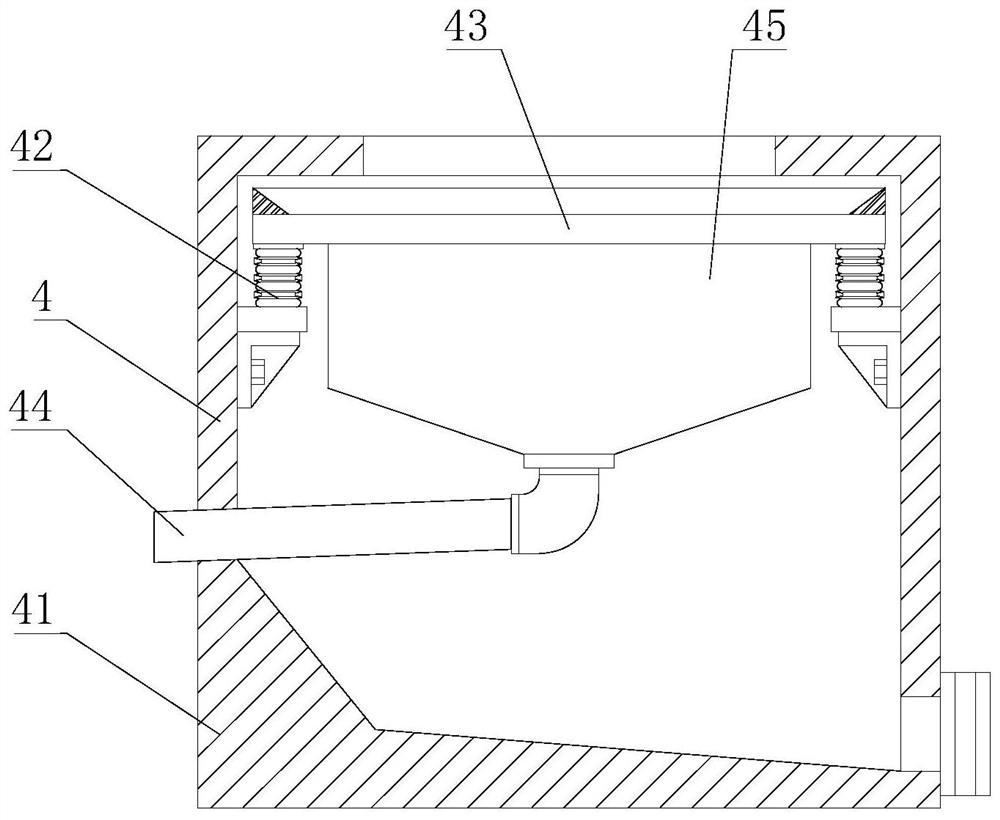

[0069] like Figure 1-6 As shown, on the basis of Embodiment 2, the present invention provides a technical solution: preferably, the screening and recovery mechanism 4 includes a support cylinder 41, the support cylinder 41 is fixedly connected to the bottom of the crusher body 1, and the support cylinder 41 is inside the support cylinder 41. An elastic seat 42 is fixedly installed on the side of the cavity, a collecting frame 43 is fixedly installed on the top of the elastic seat 42, a screening frame 45 is fixedly connected to the bottom of the collecting frame 43, and a fixed inclined tube 44 is fixedly installed on the left side of the support cylinder 41. A transmission support rod 46 is fixedly welded on the inner wall of the sub-frame 45, and an initial vibration box 47 is fixedly welded at one end of the transmission support rod 46 away from the inner wall of the screening frame 45. The inner cavity of the box 47 is provided with a vibration generator body, the bottom ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap