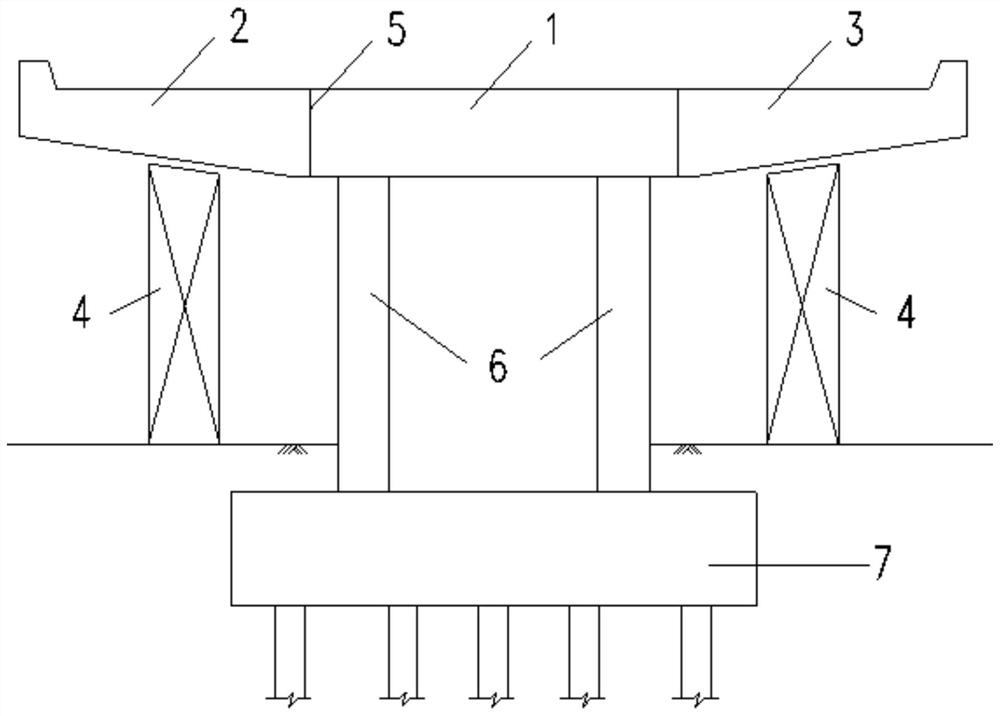

Nested standardized prefabricated assembled bent cap and construction method thereof

A prefabricated assembly and construction method technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of traffic impact on both sides, the saving of unfavorable resources, and the inability of the template to be used in general, so as to speed up the construction speed and facilitate the construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

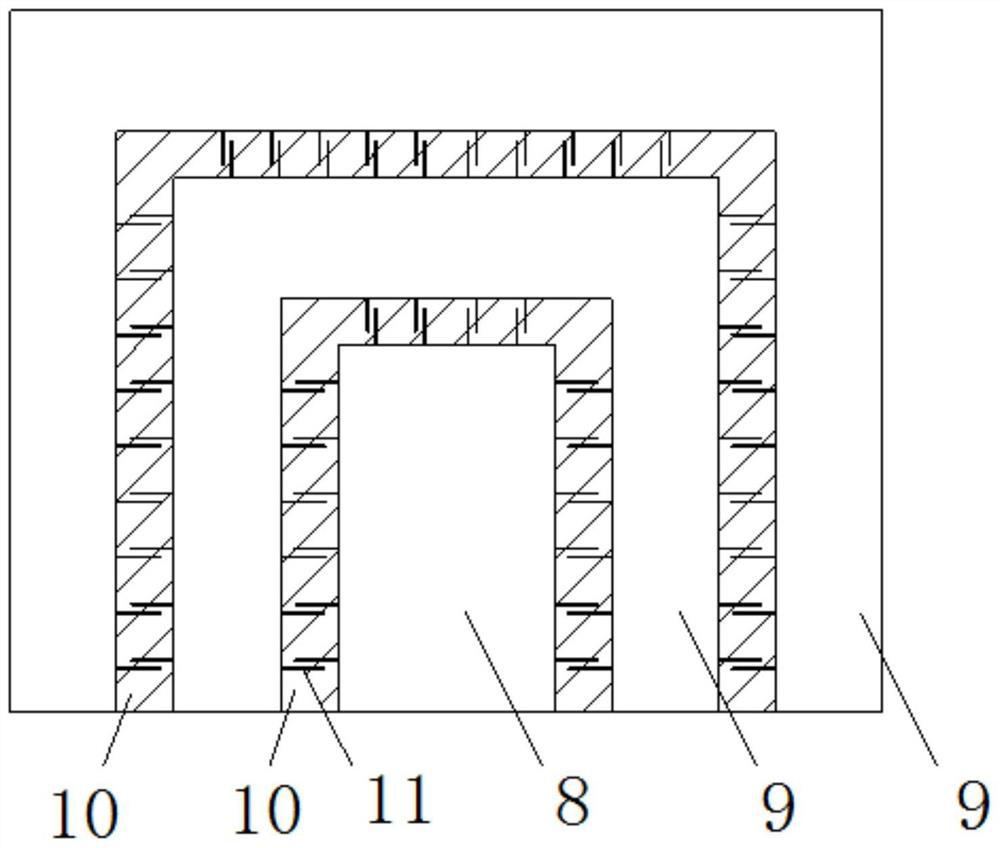

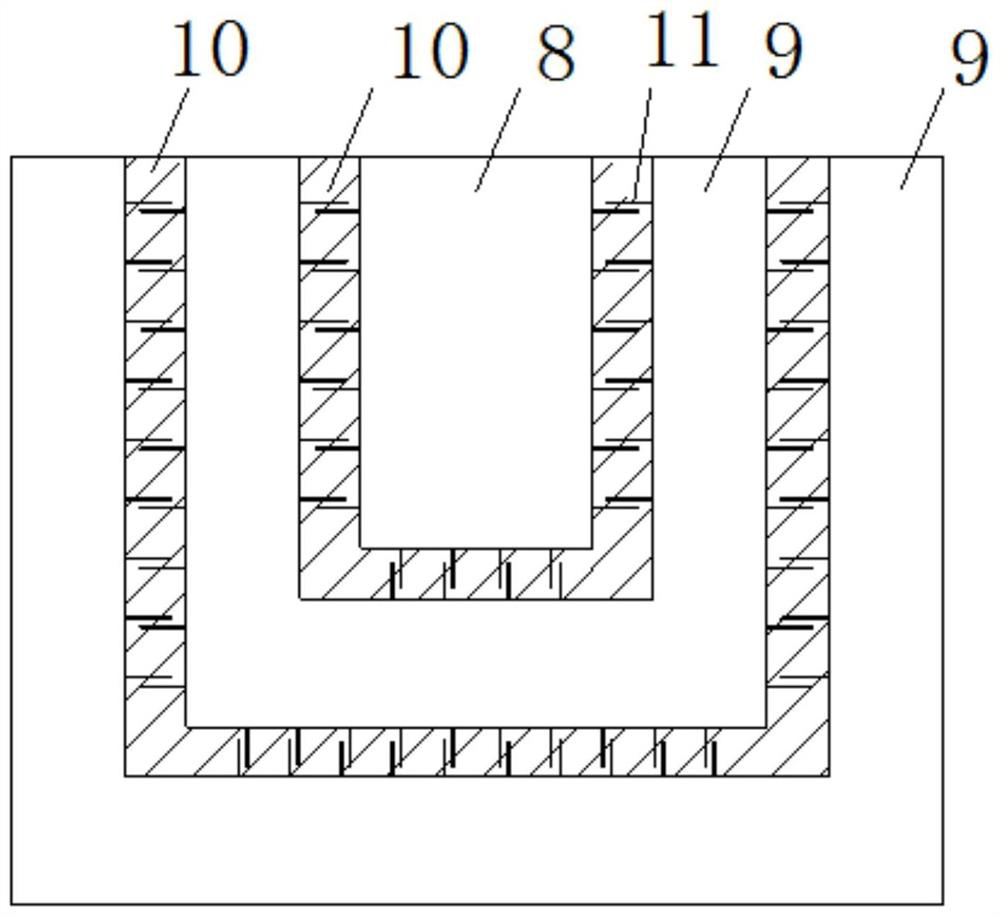

[0033] like figure 2 and image 3 As shown, the nested standardized prefabricated assembled cover beam; including prefabricated core block 8 and at least one prefabricated nested block 9;

[0034] The prefabricated core block 8 is a rectangular strip structure, the length can be determined according to the length of the actual project cover beam, and the three sides in the length direction are nested in the embedding groove of the first prefabricated nesting block 9;

[0035] The length of each prefabricated nesting block 9 is matched with the prefabricated core block 8, and is a strip-shaped structure with a cross-section of a "concave" shape, and the middle part of the surface on one side along the length direction is provided with embedded grooves penetrating both ends;

[0036] The embedding groove of each prefabricated nesting block 9 matches the shape of the previous prefabricated nesting block 9 , or matches the shape of the prefabricated core block 8 .

[0037] In s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com