Novel autoclaved heat-preservation light aerated block

An air-entraining block, lightweight technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of difficult distance control, poor card and effect, poor stability, etc., to improve stability, improve tightness, Easy to connect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

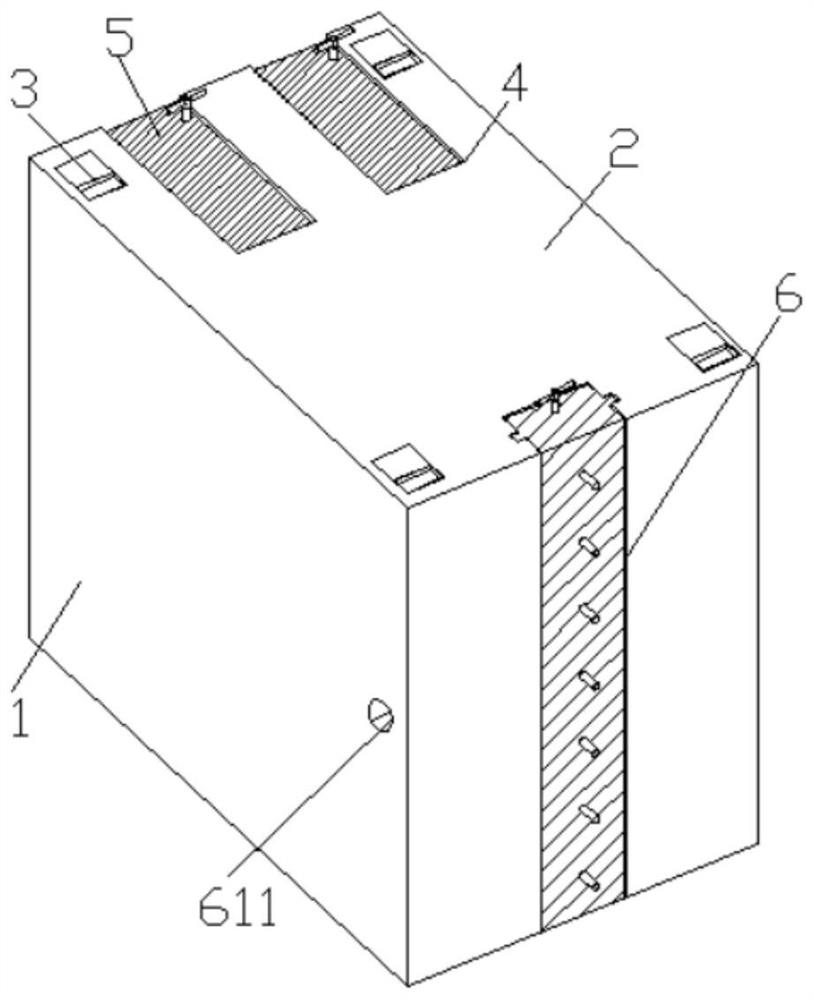

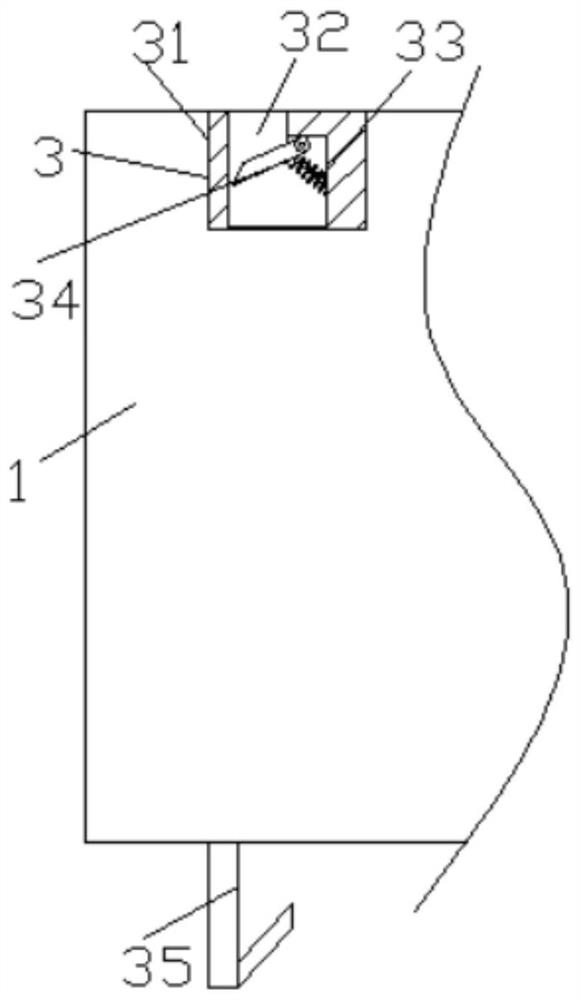

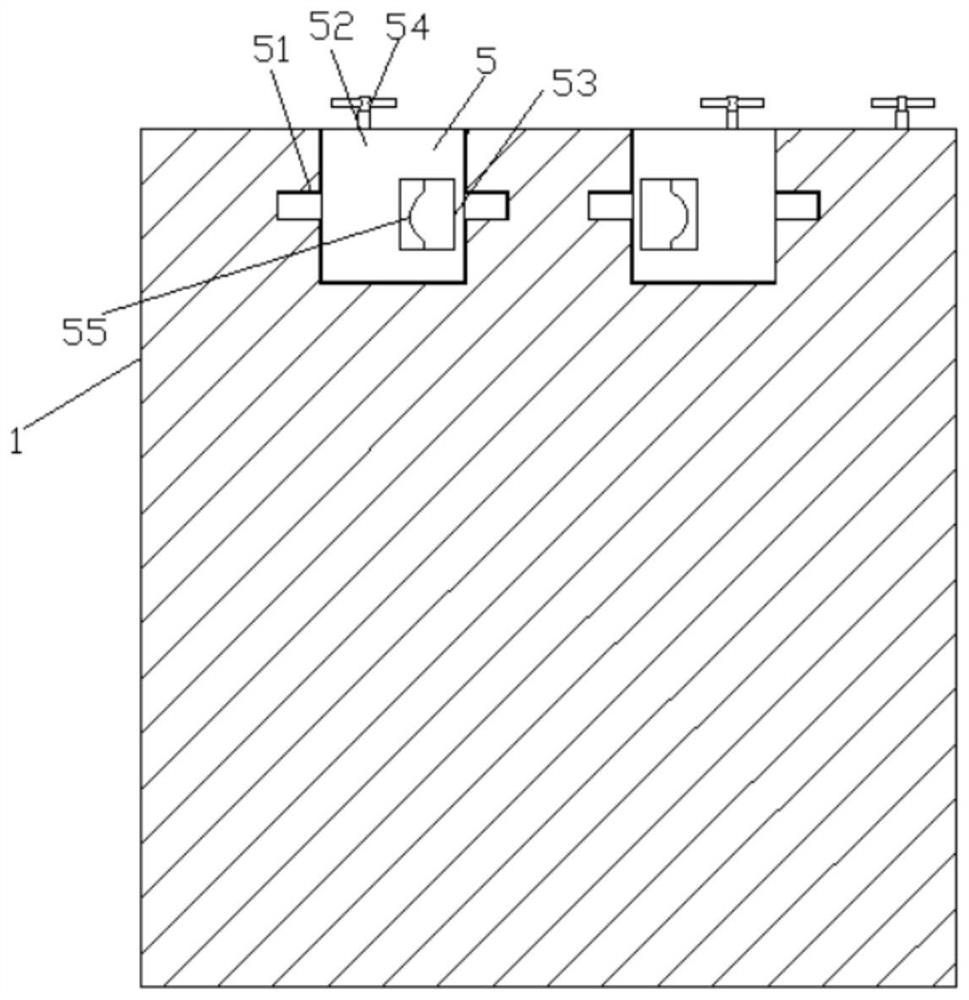

[0034] see figure 1 and figure 2 , a new type of autoclaved thermal insulation lightweight aerated block of the present invention, the main body 1 of the aerated block, the top part 2, the connecting assembly 3, the chute 4, the card and the assembly 5 and the limit assembly 6, the top of the main body 1 of the aerated block A top part 2 is provided, a chute 4 is provided at the left end of the main body 1 of the gas filling block, and the connecting assembly 3 is connected with the four corners of the top part 2. The connecting assembly 3 includes a limit frame 31, a guide cavity 32, a return spring 33, a card and a support The plate 34 and the upper plate 35, the limit frame 31 is embedded in the top part 2, which can provide the card and the limit space, the limit frame 31 is provided with a guide cavity 32, which is convenient for the upper support plate 35 to be inserted, and the side of the guide cavity 32 It is elastically connected with the return spring 33, which ca...

Embodiment 2

[0039] In a new type of autoclaved heat preservation and lightweight aerated block of the present invention, the upper and lower ends of the inner left part of the inner comprehensive plate 61 are rotatably connected with the receiving rod 63 , and the right side of the inner comprehensive plate 61 is slidably connected with the side of the limit push rod 66 .

[0040] The present invention provides a novel autoclaved thermal insulation lightweight aerated block through improvement, and its working principle is as follows;

[0041] First, when using the device, first place the device in the work area;

[0042] Second, when connecting the air-entraining block main body 1 at the upper and lower ends, the upper plate 35 at the bottom of the air-entraining block main body 1 at the upper end can be inserted into the guide cavity 32 in the limit frame 31 at the upper end of the air-entraining block main body 1 Inside, the upper plate 35 can press the card and the support plate 34 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com