Anti-static hydrogenation gun for hydrogen refueling station

A technology of hydrogen refueling station and hydrogen refueling gun, which is applied in the method of container discharge, equipment loaded into pressure vessel, container filling method, etc., can solve the problems of hydrogen loss, waste, danger of hydrogen refueling station, etc. The effect of reducing the loss of equipment, facilitating recycling and reuse, and reducing equipment leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

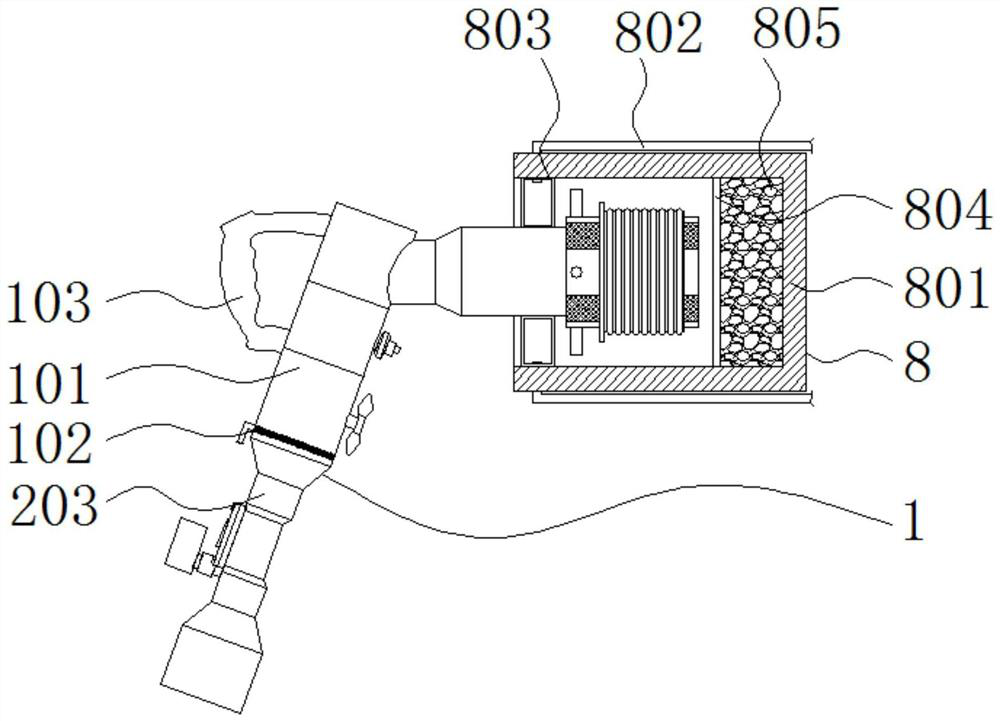

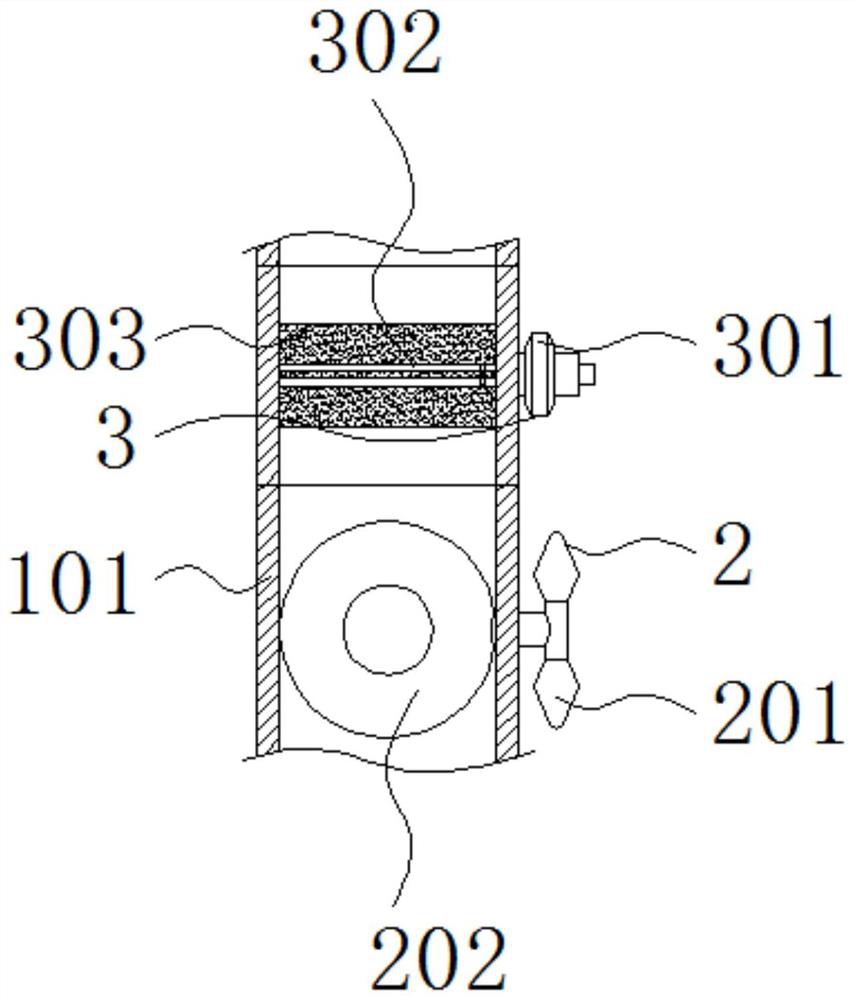

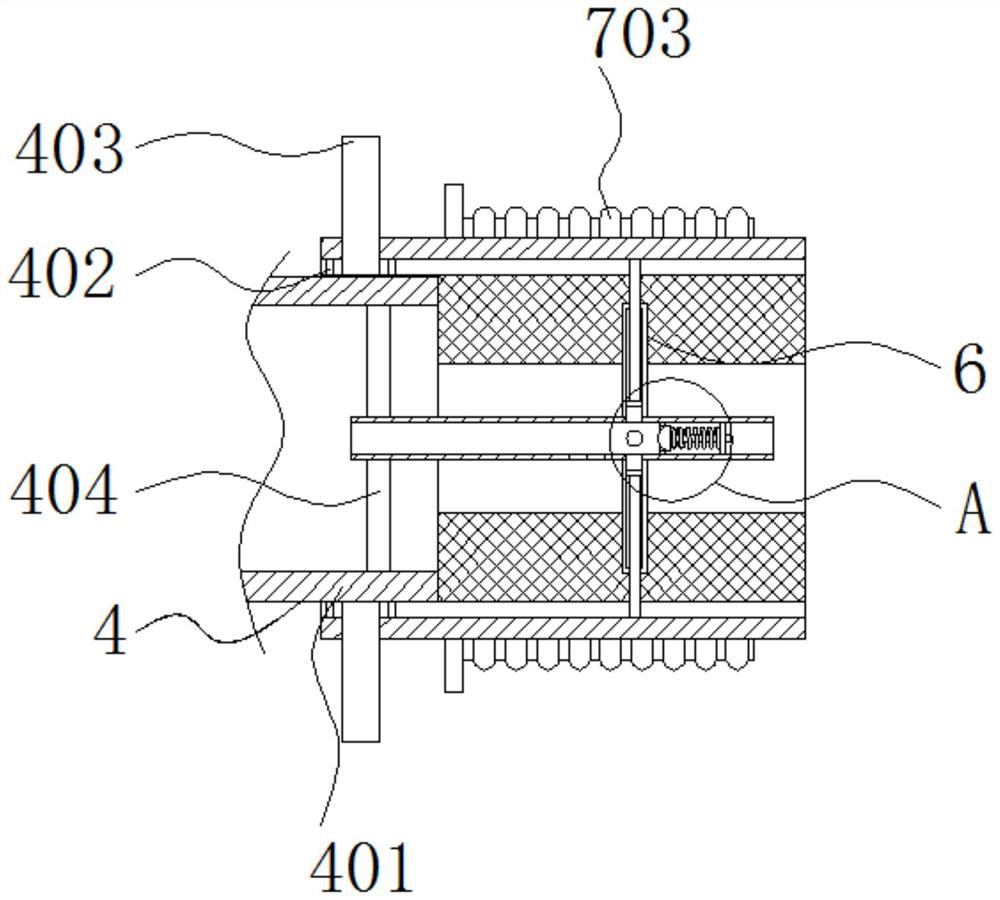

[0061] like figure 1 As shown, an anti-static hydrogen refueling gun for a hydrogen refueling station includes a casing mechanism 1 including: an outer casing 101; 101 and the static electricity on the valve mechanism 2 are conducted away, so as to prevent the static electricity carried by human hands or the outer casing 101 from affecting hydrogenation; the handle 103 is fixedly installed on the left side of the outer casing 101, outside the variable sleeve mechanism 7 An absorption mechanism 8 is provided, and the absorption mechanism 8 includes: a box body 801; an inflation pipe 802 is connected to the upper and lower ends of the box body 801. The connection between the connector 401 and the absorption mechanism 8 leaks air; the airbag 803 is sealed, which is fixed at the inner left end of the box body 801; the grid plate 804 is installed in the inner middle of the box body 801; In the space surrounded by the grid 804 and the box body 801, the hydrogen leaked from the equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com