Automatic protection type high-pressure hydrogen filling hose structure and protection method thereof

A high-pressure hydrogen, automatic protection technology, applied in the container filling method, container discharge method, pipe components and other directions, can solve the problems of violent shaking of the hose, separation, casualties, etc., and achieve the effect of avoiding property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

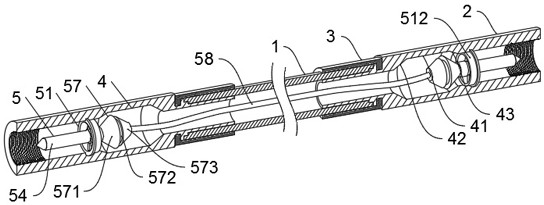

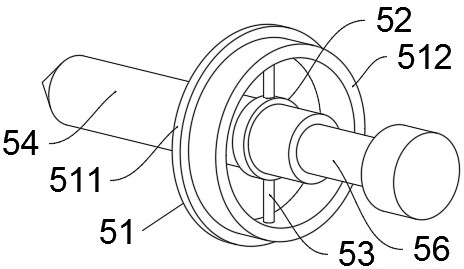

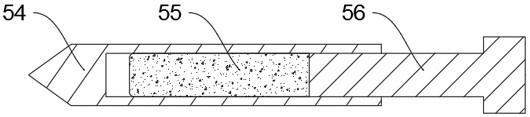

[0039]Embodiment: In the use of the present invention, when a catastrophic failure occurs such as the separation of the joint 2 from the pipe body 1, the severe damage of the pipe body 1 or the excessive extension of the pipe body 1, the pipe body 1 will continue due to the high-pressure hydrogen being ejected through the crack. Swing violently, and then make the wire rope 58 taut or swing, when the pulling force of the wire rope 58 is greater than the magnetic force between the outer magnetic rod 54 and the inner magnetic rod 55, the inner magnetic rod 55 begins to move in the direction of the pipe body 1, thereby making the blockage The plate 57 moves in the direction of the pipe body 1 until the second side plate 573 contacts the second inclined surface 43. At this time, the circulation channel between the joint 2 and the pipe body 1 is blocked by the blocking plate 57, and hydrogen cannot enter the pipe body. 1 inside, thereby preventing the tube body 1 from shaking violent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com