Novel efficient oil smoke purification device

A kind of oil fume purification and high-efficiency technology, which is applied in the direction of oil fume removal, transportation and packaging, and household stoves/stoves. Labor intensity, the effect of ensuring the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

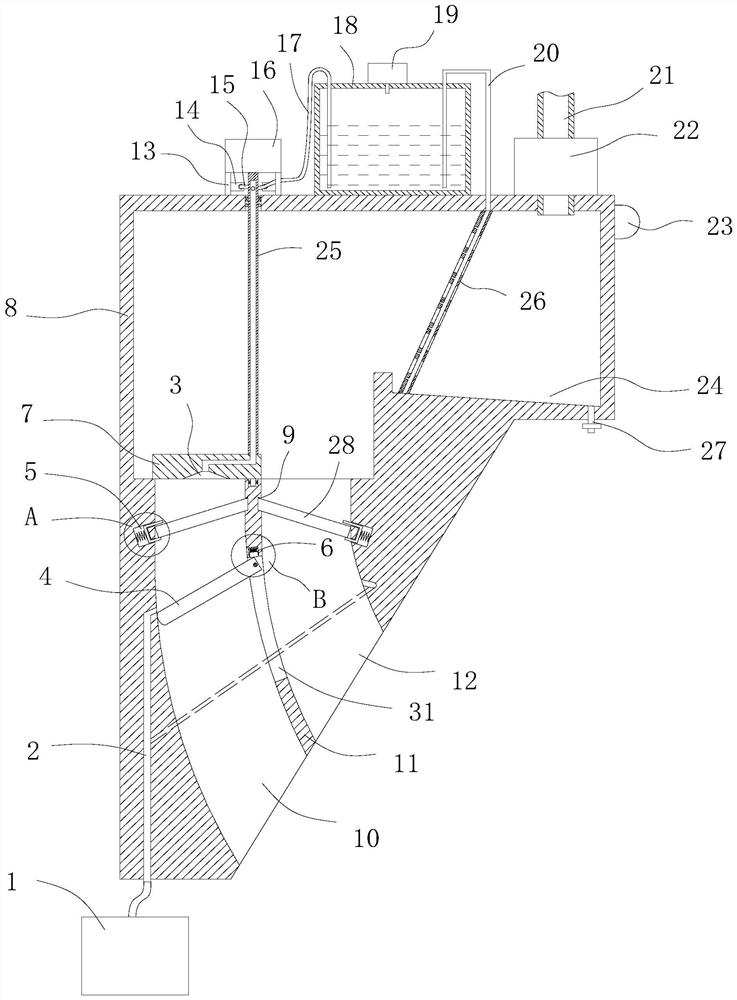

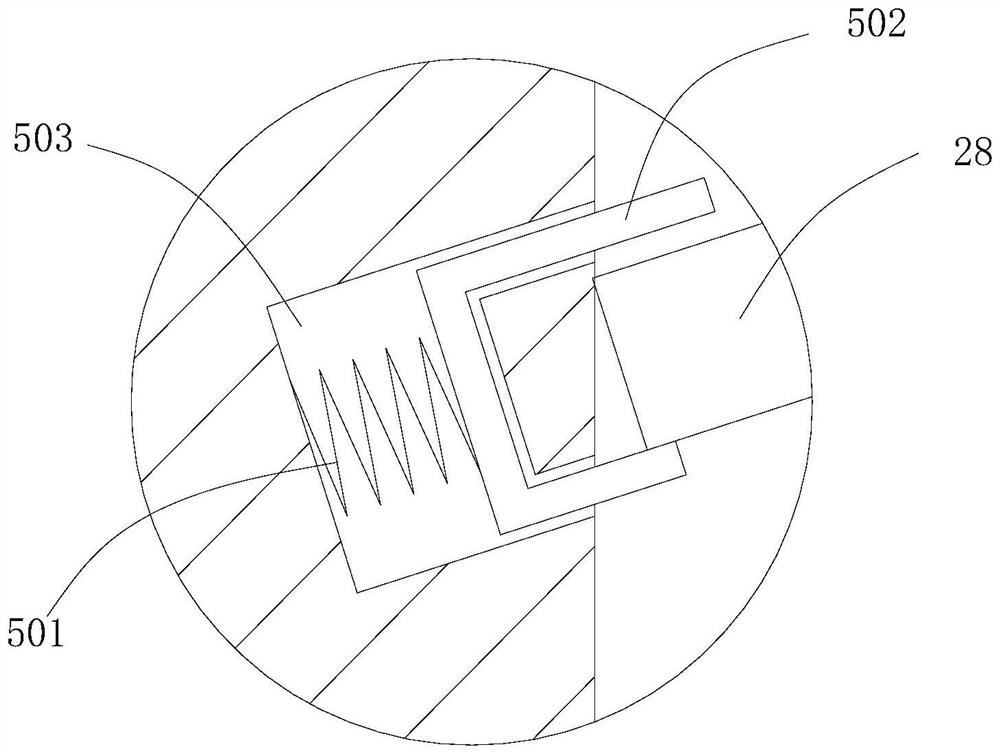

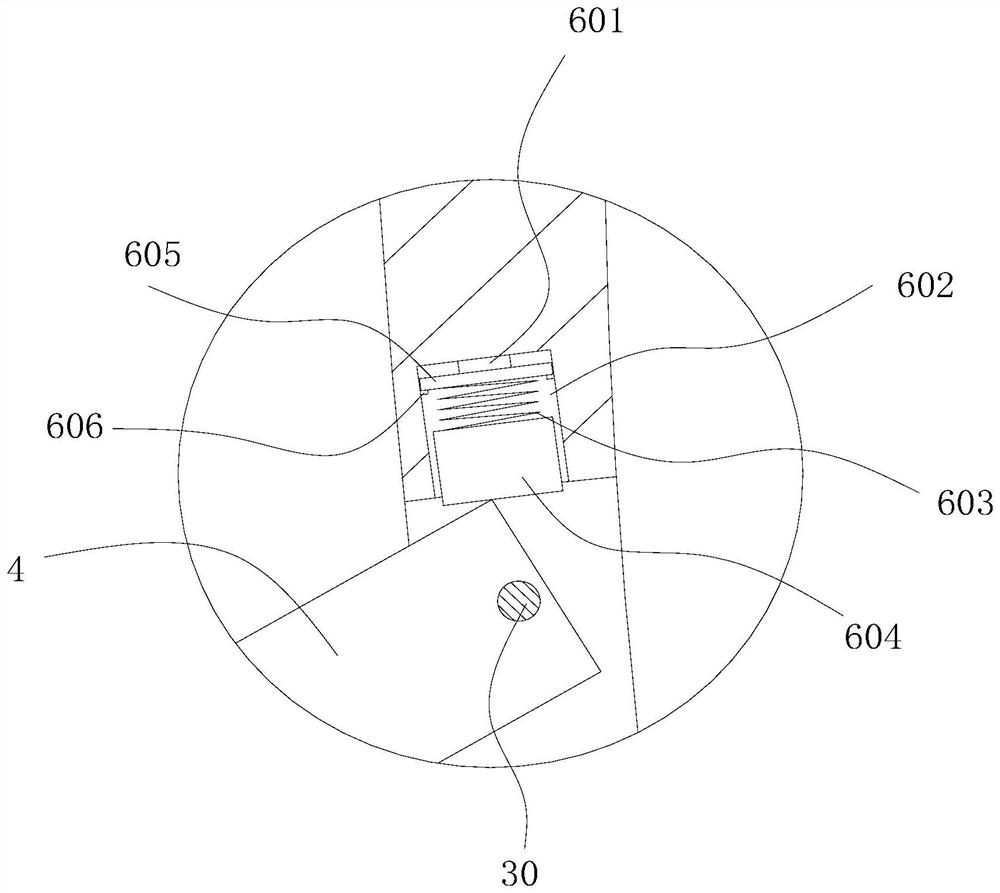

[0052] A novel high-efficiency oil fume purification device includes a casing 8, the top of the casing 8 is connected with an exhaust pipe 21, the exhaust pipe 21 is provided with a suction pump 22, and the lower end of the casing 8 is provided with a general air intake The main air inlet duct is provided with a partition 11, which divides the general air inlet duct into a first air inlet duct 10 and a second air inlet duct 12. The first air inlet duct 10 and the second air inlet duct 12. A filter screen 28 is provided in the two air inlet pipes 12. An opening 31 located below the filter screen 28 is formed on the partition plate 11. The upper end of the opening 31 is rotatably connected with a rotating shaft 30, and the rotating shaft 30 is fixedly connected with a rotating shaft 30. The baffle plate 4 is adapted to the inner walls of the pipes of the first air inlet duct 10 and the second air inlet duct 12. The rotating shaft 30 is connected with a self-locking motor 32, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com