Multi-working-condition fog-dissipation water-saving noise-reduction cooling tower

A technology for cooling towers and multi-working conditions, applied in the field of cooling towers, can solve problems such as changing the use mode, cooling towers with a single open tower or closed tower, and not suitable for multi-working conditions, so as to reduce the height of water spraying and improve Heat exchange efficiency and overall noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

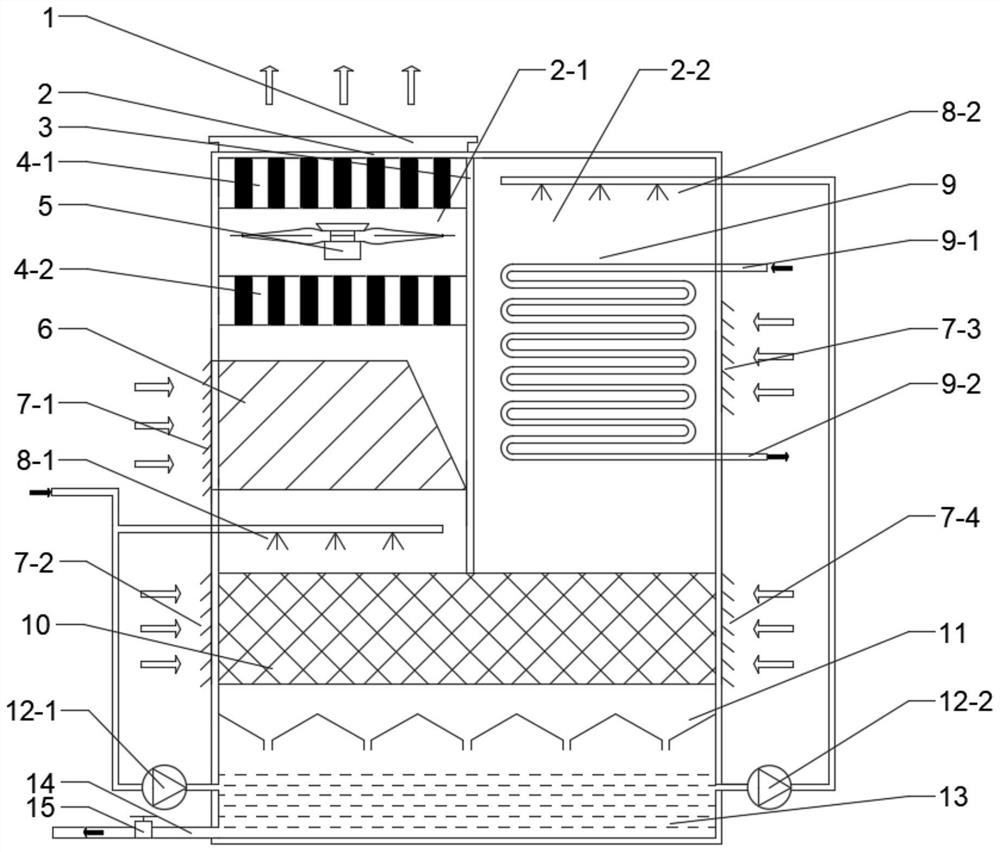

[0032] like Figure 1-Figure 8 As shown in the figure, the present invention is a multi-working-condition mist-eliminating, water-saving, noise-reducing cooling tower, comprising a tower body 2, and the inner cavity of the tower body 2 is divided into an upper cavity and a lower cavity;

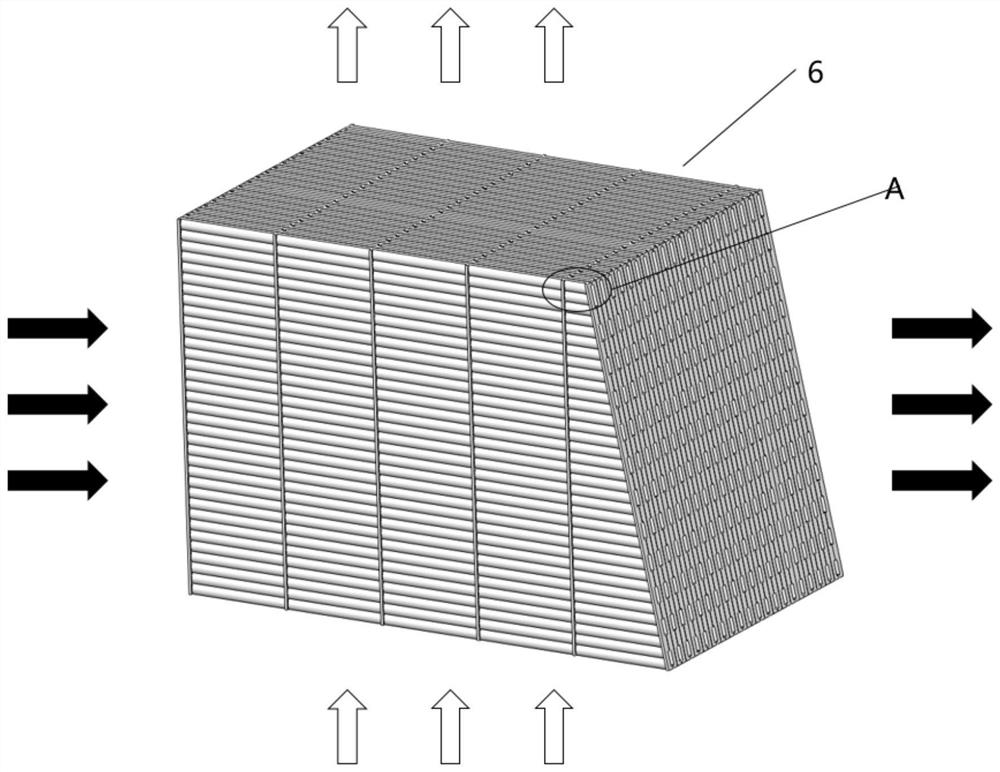

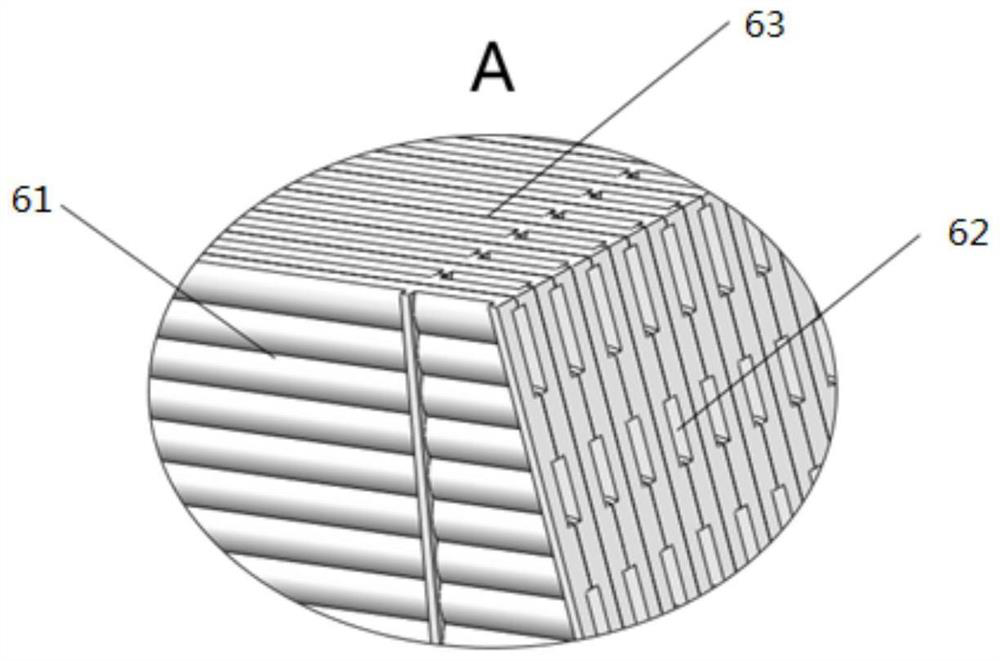

[0033] The upper cavity of the tower body 2 is provided with a partition 3, and the partition 3 divides the upper cavity into a left cavity 2-1 and a right cavity 2-2, and the left cavity 2-1 goes from top to bottom The bottom is provided with an air outlet 1, a fan 5, a mist elimination module 6 and a first spray device 8-1 in sequence, and a first shutter 7-1 is provided on the side wall of the tower body 2 facing the mist elimination module 6. , the right chamber 2-2 is provided with a second spray device 8-2 and a heat exchanger 9 in sequence, the heat exchanger inlet 9-1 is located above the heat exchanger outlet 9-2, and the heat exchanger 9 is facing A third louver 7-3 is arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com