Digital electronic detonator presplitting blasting engineering method

A technology of digital electronic detonator and pre-splitting blasting, which is applied in the field of digital electronic detonator pre-splitting blasting engineering, can solve the problems of large shock waves, loud noises, and large seismic wave hazards, and achieves improved efficiency, simple operation methods, and elimination of seismic waves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

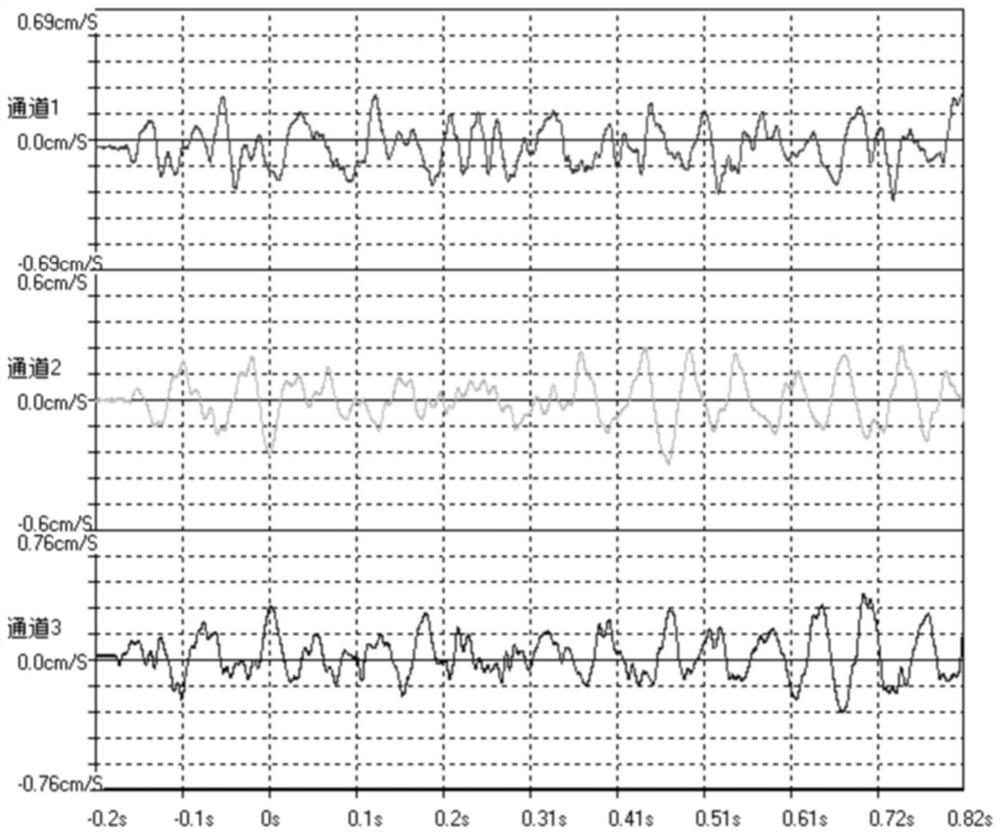

[0057] Example 1: Channel 1

[0058] One of the blasting operation points: there is a restaurant 160 meters on the north side, residents 200 meters on the west side, and 380 meters away from a nearest town. The conditions are extremely complex and cannot be carried out with traditional pre-split blasting. The surrounding hotels, residents and a nearest town were not affected, and the slope treatment work was completed.

[0059] Include the following steps:

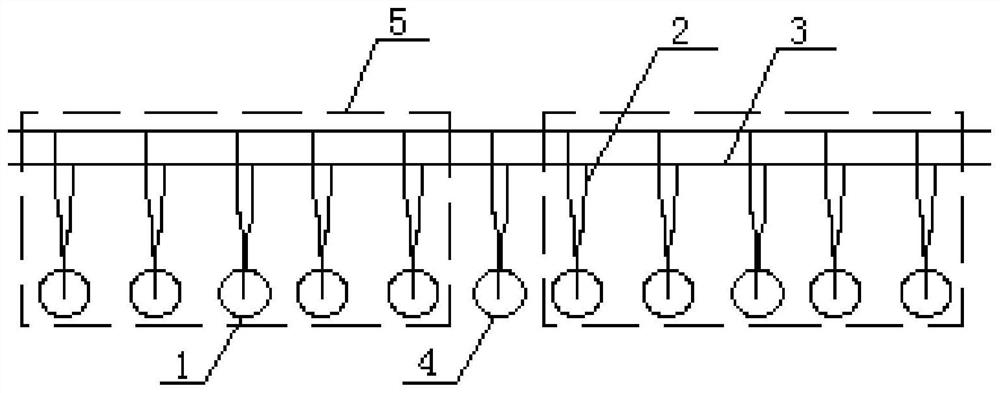

[0060] Step S1, densely drilling holes along the straight line at the boundary of the reserved working face for engineering blasting, with a hole diameter of 50 mm and a spacing of 500 mm to form pre-split blasting holes 1;

[0061] Step S2, connect the detonating cord and the charge coil to form a charge string, use uncoupled charge to load into the pre-split blast hole 1, insert the charge coil at the top of the blast hole into the digital electronic detonator 2, and block the pre-split blast hole 1 at the top;

[0062] ...

Embodiment 2

[0065] Example 2: Channel 2

[0066] The second blasting operation point: It is closer than the first operation point, 130 meters away from the hotel on the north side, 180 meters away from the residents on the west side, and 340 meters away from a nearest town. Using this technical method, pre-split blasting was carried out, and the surrounding restaurants, residents and A recent town was not affected.

[0067] Include the following steps:

[0068] Step S1, densely drilling holes along the straight line at the boundary of the reserved working face for engineering blasting, with a hole diameter of 90 mm and a spacing of 1000 mm to form pre-split blasting holes 1;

[0069] Step S2, connect the detonating cord and the charge coil to form a charge string, use uncoupled charge to load into the pre-split blast hole 1, insert the charge coil at the top of the blast hole into the digital electronic detonator 2, and block the pre-split blast hole 1 at the top;

[0070] Step S3, all ...

Embodiment 3

[0073] Example 3: Channel 3

[0074] The third blasting operation point: closer than the first two operation points, only 90 meters from the hotel on the north side, 100 meters from the residents on the west side, and 300 meters from a nearest town. This technical method was used to carry out pre-split blasting, which was completed at one time. The surrounding hotels, residents and a nearest town were not affected at all.

[0075] Include the following steps:

[0076] Step S1, densely drill holes along the straight line at the boundary of the reserved working face for engineering blasting, with a hole diameter of 130 mm and a spacing of 1500 mm to form pre-split blasting holes 1;

[0077] Step S2, connect the detonating cord and the charge coil to form a charge string, use uncoupled charge to load into the pre-split blast hole 1, insert the charge coil at the top of the blast hole into the digital electronic detonator 2, and block the pre-split blast hole 1 at the top;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com