Whole cabinet test center

A test center and whole cabinet technology, applied in the direction of machine/structural component testing, measuring devices, instruments, etc., can solve time-consuming and labor-intensive problems, save labor costs, improve test efficiency, and facilitate the placement of cabinets in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] At present, there are mainly two kinds of test sites for the whole cabinet. One kind of site only provides basic power and cooling liquid, and the whole cabinet server is placed in a cold environment. It is impossible to meet the large-scale and long-term testing requirements of the entire cabinet server; another method is to transform the cabinets in the micro-modular data center into test positions through prefabrication. In this way, the cold aisle can be retained, and the cooling capacity of the data center is greatly improved. However, the manual loading and unloading method cannot ensure that the cabinets move in a straight line, and the test is time-consuming and labor-intensive.

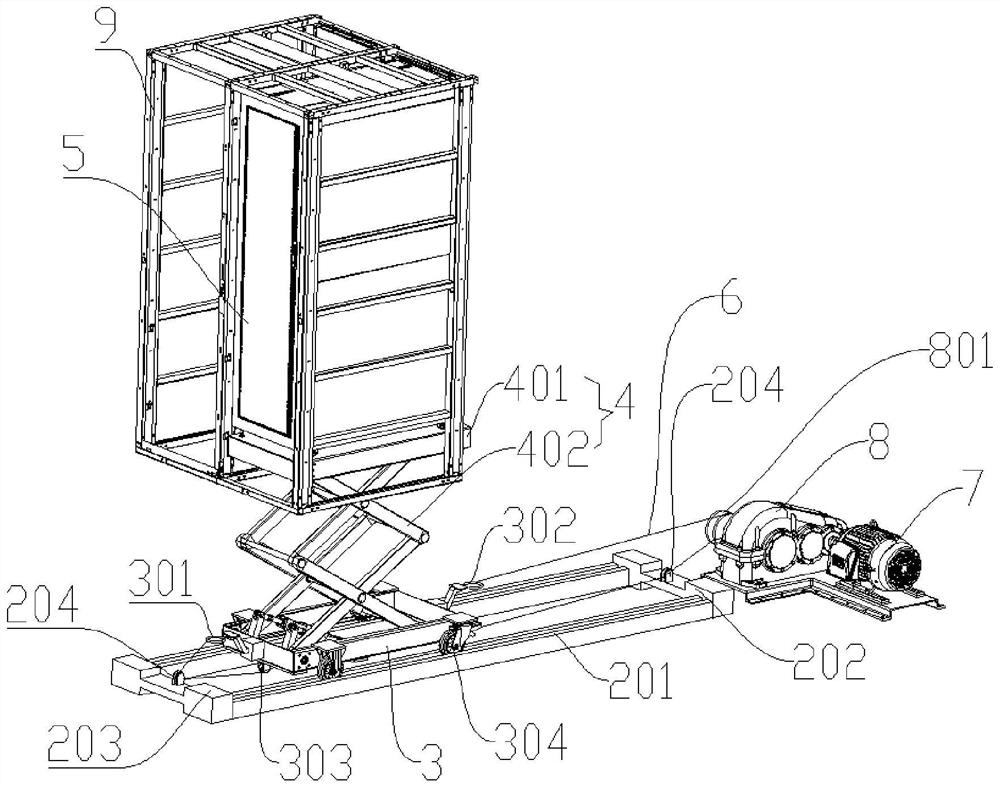

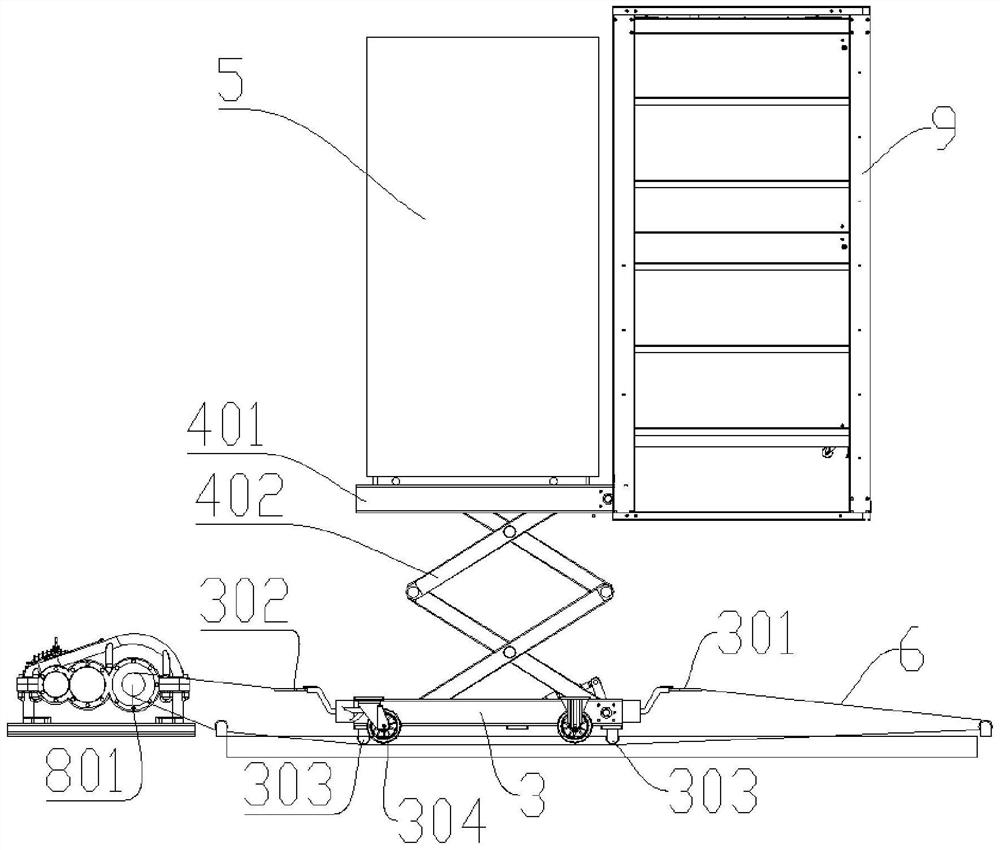

[0031] To this end, this embodiment provides a complete cabinet test center, which can ensure that the cabinet 5 to be tested moves in a straight line, thereby saving labor costs.

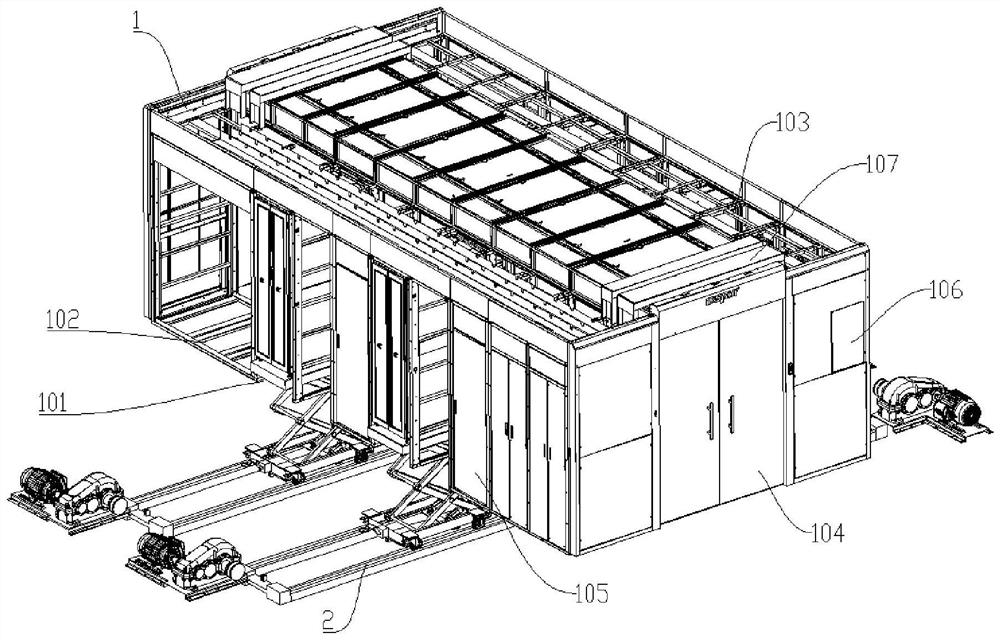

[0032] In one embodiment, as figure 1 As shown, the whole cabinet test center includes a micro-module d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com