Magic wand type array eddy current probe and sensor and detection method thereof

A technology of eddy current detection and eddy current probes, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of inability to copy general detection probes, not too high, promotion restrictions, etc., and achieve simplification of hardware operation structure and procedures, and flexibility The effect of selective detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

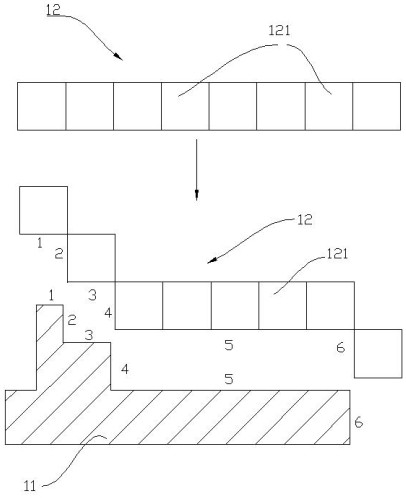

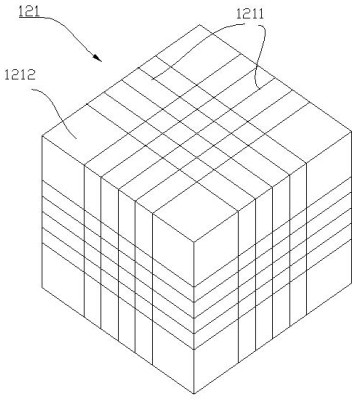

[0030] like figure 1 and figure 2 As shown, an eddy current detection sensor is used for the eddy current detection sensor 121 of the detected object 11 of a large metal device, and includes a coil 1211 and a main body 1212. The intersection is wound around a cube, wherein, during detection, the six surfaces of the sensor cube-shaped main body form the same non-directional eddy current detection surface that intersects in pairs. That is, the same non-directional detection sensors are formed on the six surfaces of the detection sensor cube.

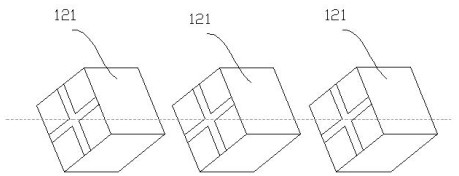

[0031] like figure 2As shown in the figure, three sets of identical coils are alternately used as transmitting and receiving coils in a time interval, and the best detection signal is selected as the required detection result. In each time period, the six faces of the detection sensor cube take turns to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com