Environment test condition cutting method and environment test control system based on equipment environment profile and environment equivalent analysis

An environmental test and environmental technology, applied in the field of environmental test, can solve problems such as the inability to quantify the characterization of environmental equivalents, and achieve the effects of shortening test time, rational design, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

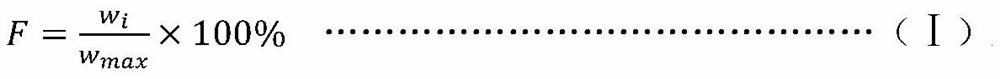

Method used

Image

Examples

Embodiment 1

[0058] A method for tailoring environmental test conditions based on equipment environmental profile and environmental equivalent analysis, the steps comprising:

[0059] Step 1: Determine the test environment factors according to the equipment service area.

[0060] Equipment or its components / materials must experience different application scenarios during its life cycle. Different application scenarios represent different environmental profiles, and environmental factors have different effects and destructive effects on equipment under each profile. Generally, in the outdoor state, the equipment is mainly affected by environmental factors such as high and low temperature, humidity and heat, and solar radiation. In the storage state in the warehouse, the influence of temperature (accumulated temperature) is more prominent, and the impact on solar radiation is small or even negligible.

[0061] In this step, the environmental factors or factor combination categories (referred...

Embodiment 2

[0140] An environmental test (computer) control system, comprising a memory, a processor and a program stored on the memory and can be run on the processor; the program includes a runnable test environmental factor data module, environmental equivalent and its conversion coefficient data modules, calculation modules, input modules and output modules;

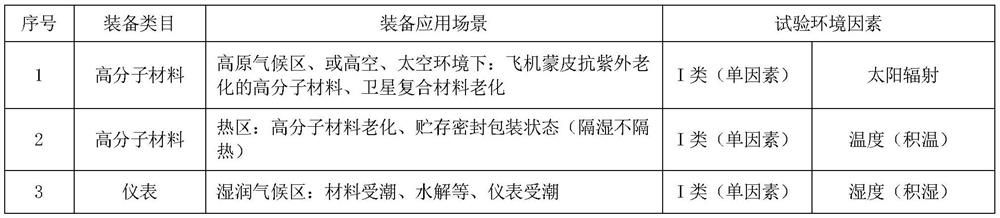

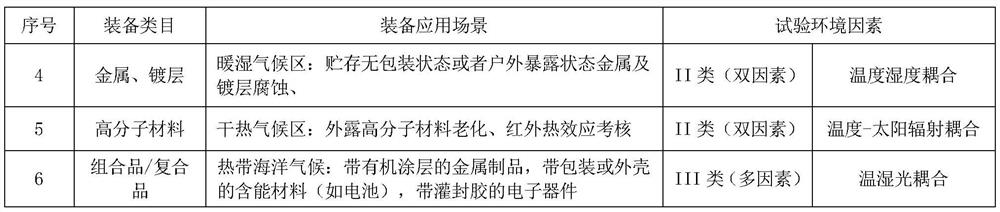

[0141] Among them, the test environment factor data module includes the content in Table 1 that can be read and called;

[0142] Table 1 Test environmental factors

[0143]

[0144] Wherein, the environmental equivalent and its conversion coefficient data module includes the contents in Table 2 to Table 6 that can be read and called;

[0145] Table 2 Storage accumulated temperature environmental equivalents and their conversion coefficients by geographical area

[0146]

[0147] Table 3 Temperature-humidity coupled environmental equivalents and their conversion coefficients by geographic region

[0148]

[0149] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com