Annular combustion chamber model with integrated head structure and assembly method

An annular combustion chamber and combustion chamber technology, applied in teaching models, connecting components, instruments, etc., can solve the problems of inability to take into account the fine structure and low cost, the complex structure of the aero-engine combustion chamber, and the difficulty of taking into account the fineness of the structure, etc. Convenient assembly design, good teaching display value, and the effect of manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

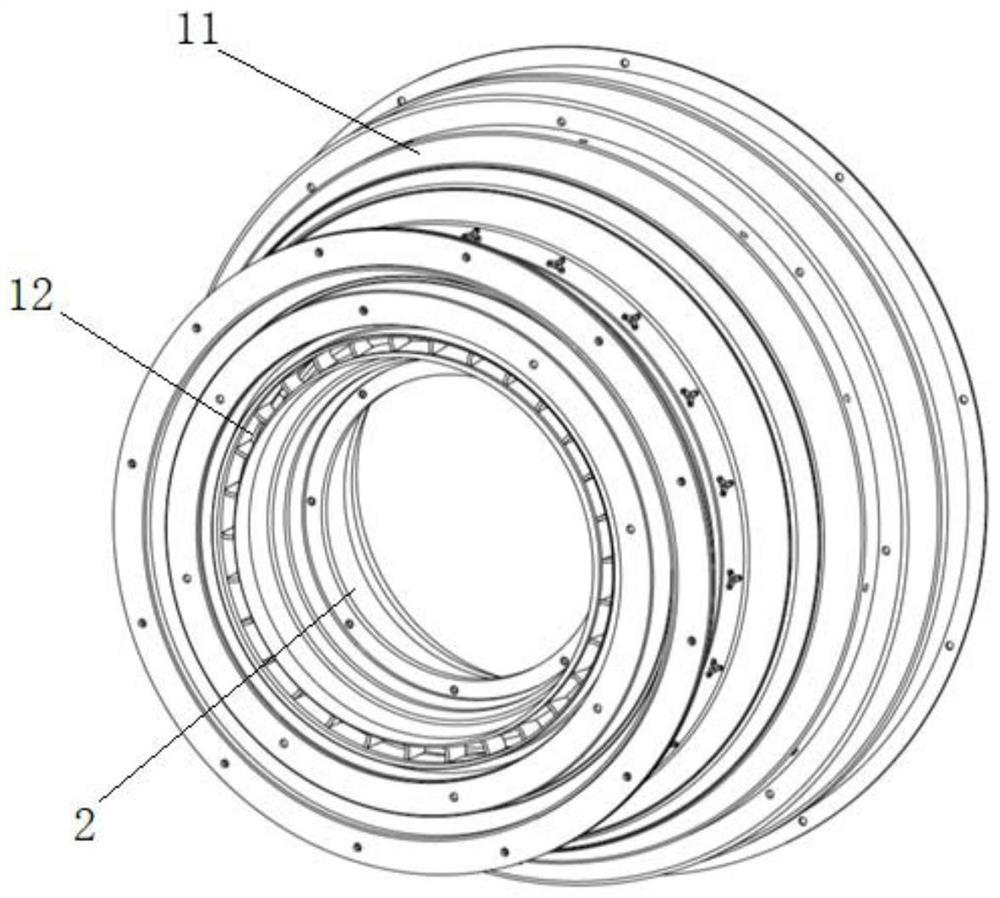

[0046]This embodiment is an annular combustion chamber model with an integrated head structure, which achieves a high-precision restoration of the typical structure of the annular combustion chamber of a modern engine. The parts involved in this embodiment can be processed and have sufficient strength under the conditions of applying the photo-curing 3D printing process. The annular combustion chamber model with an integrated head structure described in this embodiment can be combined with other parts models, including a high-pressure compressor model, a high-pressure turbine model, and a low-pressure turbine model.

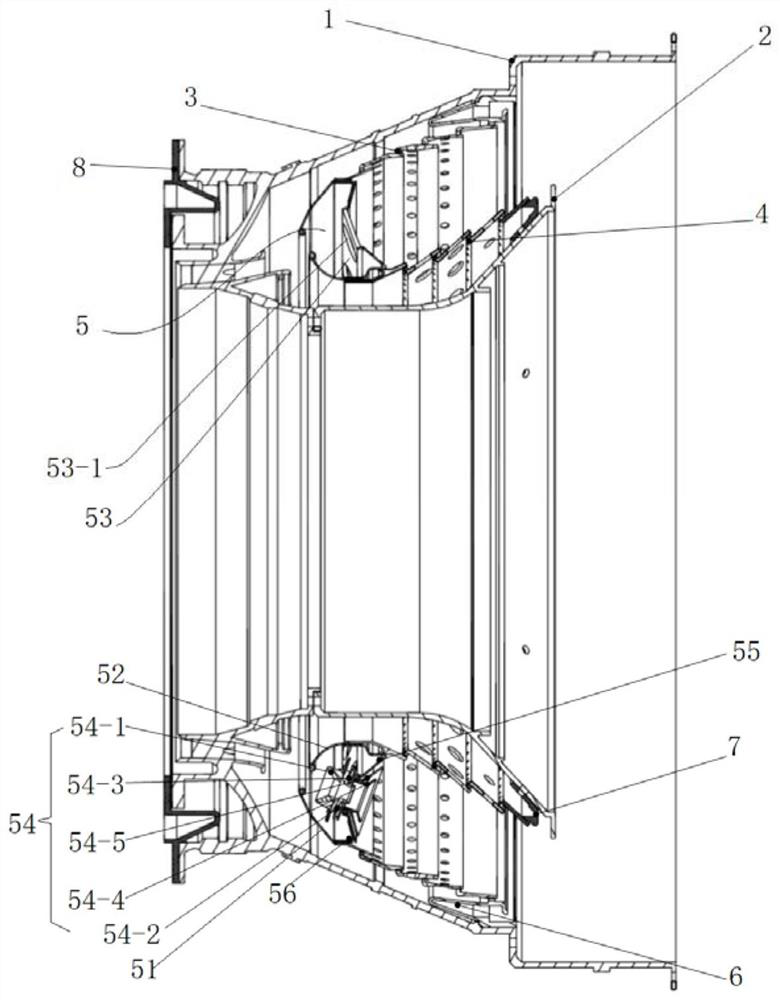

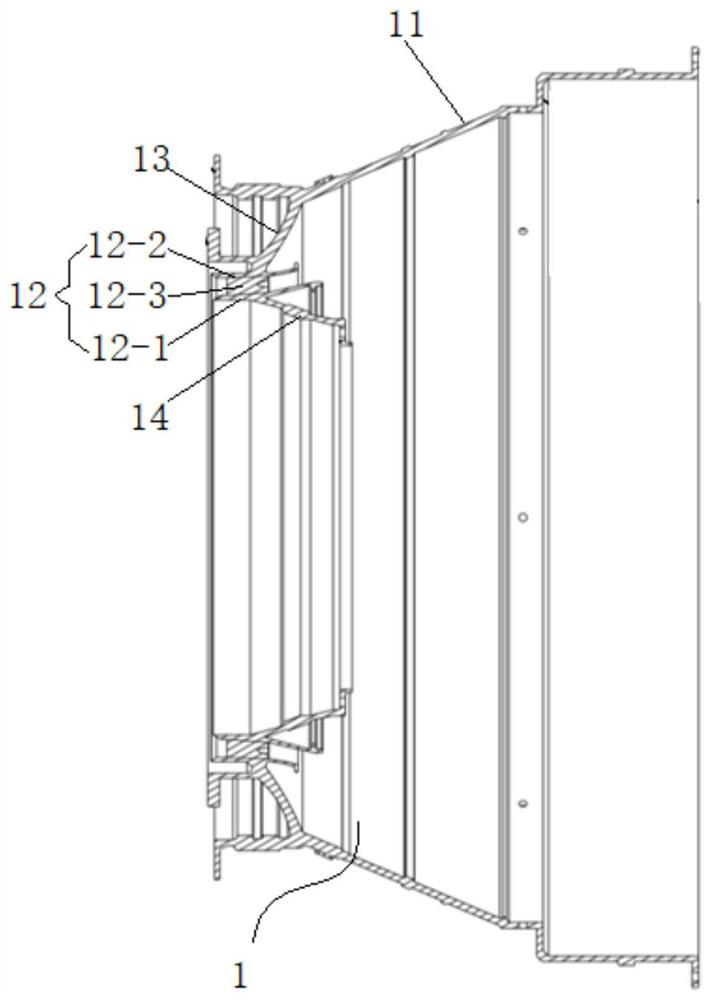

[0047] like Figure 1 to Figure 9 As shown, this embodiment provides an annular combustion chamber model with an integrated head structure, including an outdoor casing 1, an indoor casing 2, an outer casing 3 of a flame tube, an inner casing of the flame tube 4 and a flame tube head 5 ;

[0048] The combustion outdoor casing 1 includes a combustion outdoor casi...

Embodiment 2

[0067] The present embodiment provides a method for assembling an annular combustion chamber model with an integrated head structure, including the following steps:

[0068] Step 1, connect and fix the flame tube head, then connect the flame tube head with the flame tube outer shell and the flame tube inner shell respectively to form the flame tube as a whole;

[0069] Step 2, connect and fix the inner support ring with the casing in the combustion chamber, and connect the rear end of the casing in the combustion chamber to the turbine inlet guide of the high-pressure turbine model;

[0070] Step 3, install the combustion outdoor casing, and the combustion outdoor casing is connected to the combustion indoor casing, the outer support ring, and the high-pressure turbine model in sequence;

[0071] In step 4, the sealing ring is connected with the casing outside the combustion chamber, and the connection between the combustion chamber and the high-pressure compressor model is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com