Medium-salt-concentration electrolyte for lithium-sulfur battery

A lithium-sulfur battery and electrolyte technology, applied in lithium batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of capacity decay, side reactions between lithium anode and electrolyte, self-discharge during storage, etc., to achieve the proportion of use The effect of reducing and improving the dissociation ability of lithium salt and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

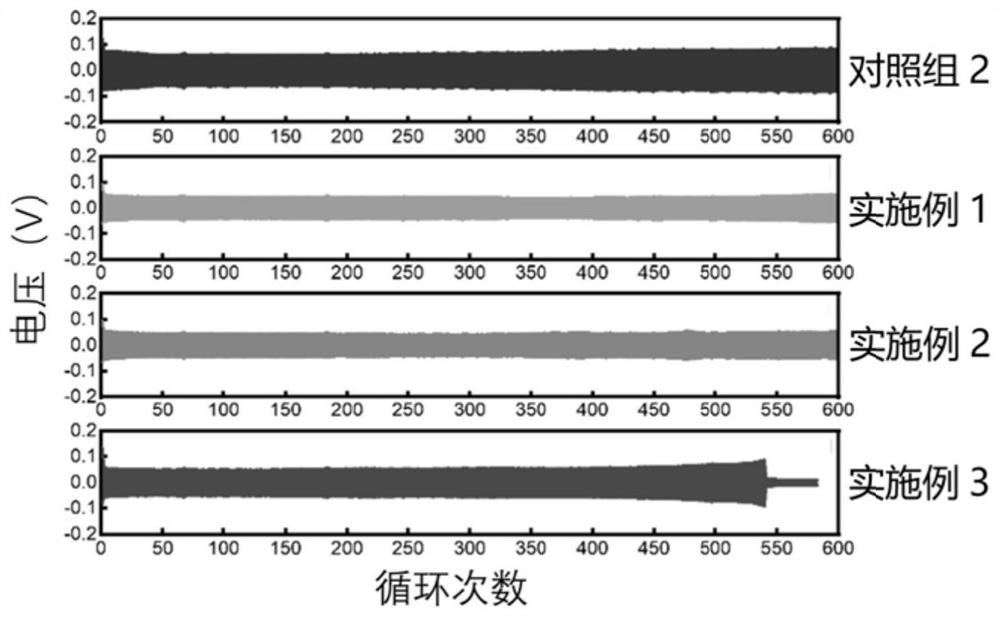

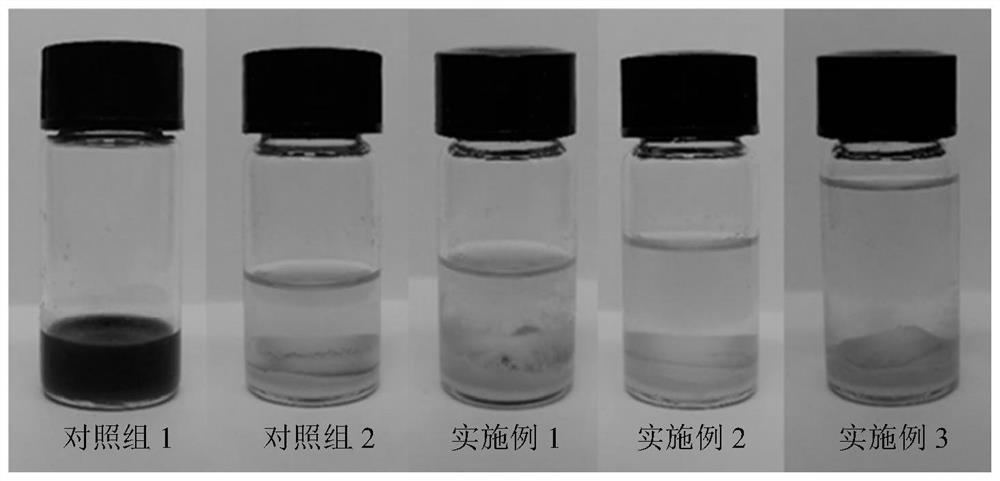

Embodiment 1

[0031] Lithium bis(trifluoromethylsulfonyl)imide, lithium bisfluorosulfonimide, tetrahydrofuran, isopropyl ether, 1,1,2,2-tetrafluoroethyl 2,2,3,3-tetrafluoro The solution was prepared with propyl ether in a ratio of 1:3:8:2:5.

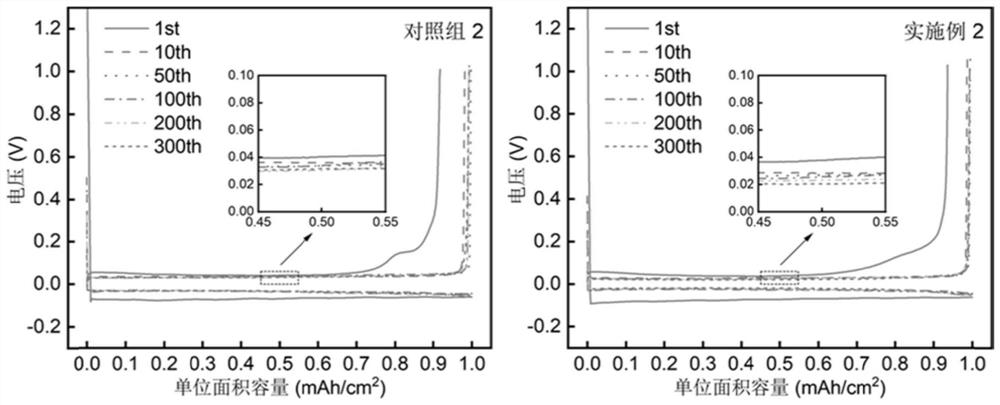

Embodiment 2

[0033] Lithium bis(trifluoromethylsulfonyl)imide, lithium bisfluorosulfonimide, tetrahydrofuran, isopropyl ether, 1,1,2,2-tetrafluoroethyl 2,2,3,3-tetrafluoro The solution was prepared with propyl ether in a ratio of 1:3:8:2:9.

Embodiment 3

[0035] Lithium bis(trifluoromethylsulfonyl)imide, lithium bisfluorosulfonimide, tetrahydrofuran, isopropyl ether, 1,1,2,2-tetrafluoroethyl 2,2,3,3-tetrafluoro The solution was prepared with propyl ether in a ratio of 1:3:8:2:18.

[0036] control group 1

[0037] The electrolyte of the control group was prepared by dissolving lithium bis(trifluoromethylsulfonyl)imide in a mixed solvent of ethylene glycol dimethyl ether-1,3-dioxolane with a volume ratio of 1:1. With a concentration of 1 mol / L, this electrolyte is the most widely used electrolyte in current lithium-sulfur batteries.

[0038] control group 2

[0039] A solution was prepared by bis(trifluoromethylsulfonyl)imide lithium, lithium bisfluorosulfonimide, tetrahydrofuran and isopropyl ether in a ratio of 1:3:8:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com